Electric windproof lever

A pull rod and electric technology, applied in the direction of transportation and packaging, load suspension components, traveling mechanism, etc., can solve problems such as incompatibility, time-consuming and laborious, and inability to realize automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention. Any similar structures and similar changes of the present invention shall be included in the protection scope of the present invention. The commas in all indicate the relationship of and.

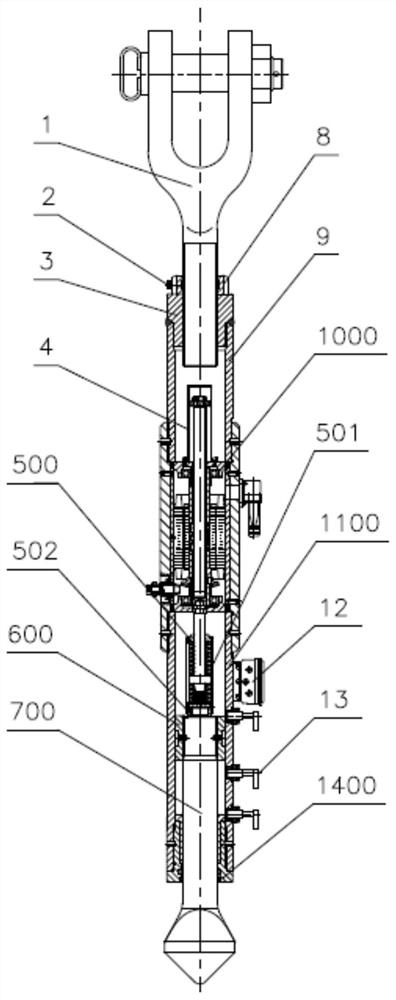

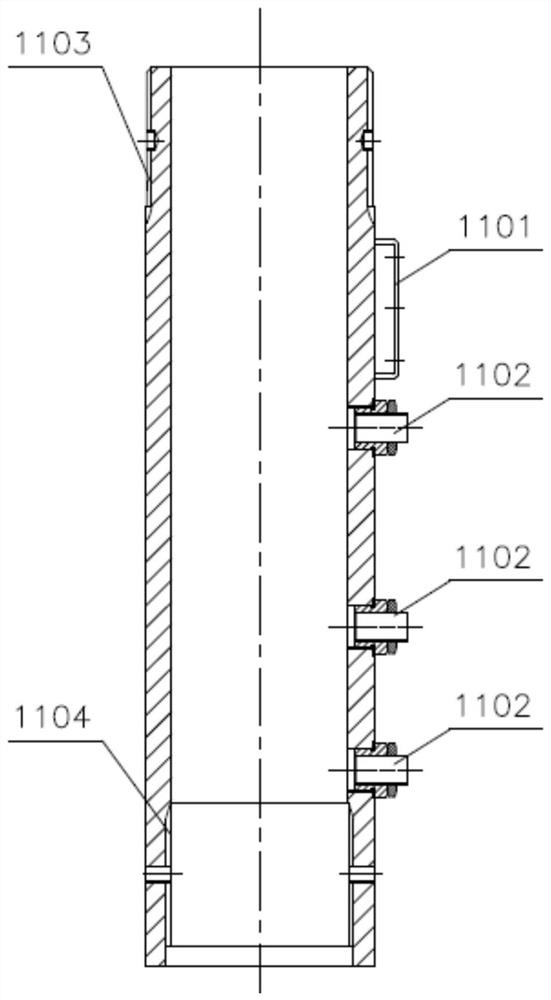

[0033] like figure 1 As shown in the figure, the new electric windproof pull rod provided by the embodiment of the present invention includes: a shackle rod 1, an upper rod 9, a lock head shaft telescopic motor 1000, a lower rod 1100, a buffer coupling 500, a lock head shaft 700, a lock head The sliding seat 600 on the shaft and the sliding seat 1400 of the lock shaft.

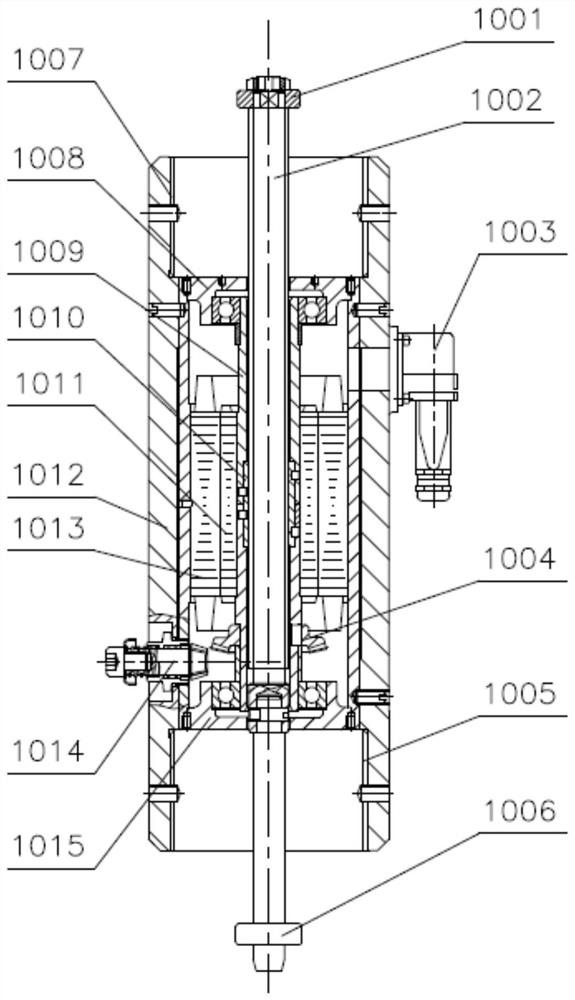

[0034] like figure 1 , figure 2 As shown, the shaft of the upper rod 9 is a steel pipe with a certain wall thickness, the upper end of the shaft of the upper rod 9 is fixed coaxially with the tubular shackle a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com