Thread-based under-pressure oil pipe leakage repairing device

The technology of oil pressure pipe and thread is applied in the field of leak repairing device for oil pipe under pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

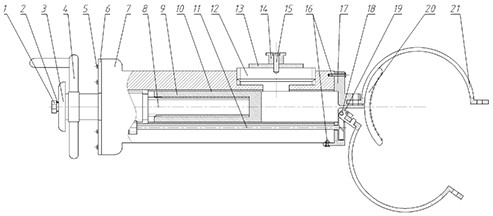

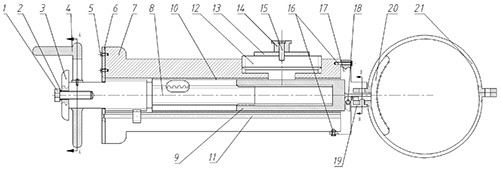

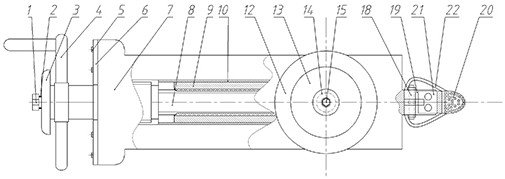

[0021] In order to make the purpose of the present invention, the technical solution and the advantages clearer, the present invention will be further elaborated below in conjunction with the accompanying drawings. Wheel, 8 main rotating rod, 9 push sleeve, 10 leak-proof partition sleeve, 5 front pressure plate bolt, 6 rear pressure plate, 7 cavity, 11 transmission gear shaft, 12 push cover, 13 gland piece, 14 knurled screw cover , 15 Push cover pressing bolt, 16 Front pressure plate bolt, 17 Front pressure plate, 18 Control gear shaft, 22 Injection needle, 19 Flange buckle, 20 Rubber hole film, 21 Universal double-hole trap flange and other parts, the specific operation Proceed as follows:

[0022] 1. Install the upper universal 21 double-hole leak-trapping flange on the groove connecting the flange port above the 17 front pressure plate of the device;

[0023] 2. Connect the 22 injection needle of the device with the 20 rubber hole film jack, and after fixing it, insert the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com