Automatic conversion method for data acquired by intelligent wagon balance

A technology for automatic conversion and data collection, which is applied in the field of automatic conversion and data collection by smart weighbridges, and can solve problems such as low efficiency, complicated process, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

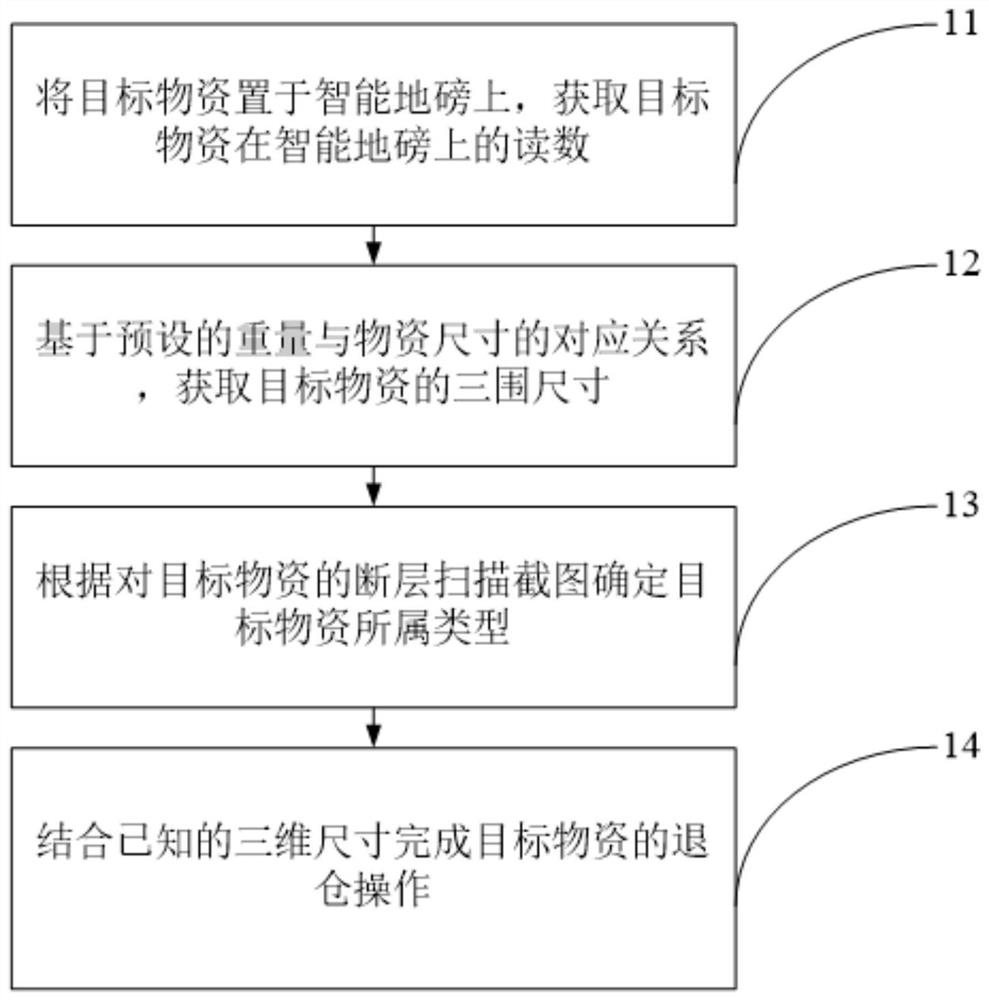

[0035] Specifically, the automatic conversion method for data collected by intelligent weighbridge proposed in the embodiment of this application, such as figure 1 As shown, the automatic conversion method includes:

[0036] 11. Put the target material on the smart weighbridge, and obtain the reading of the target material on the smart weighbridge;

[0037] 12. Obtain the measurements of the target material based on the preset correspondence between weight and material size;

[0038] 13. Determine the type of the target material according to the tomographic screenshot of the target material;

[0039] 14. Combining the known three-dimensional dimensions to complete the withdrawal operation of the target materials;

[0040] Wherein, the intelligent platform scale includes a preset number of load cells, and the load cells transmit data through wireless communication technology, and the sum of the readings of all the load cells is used as the total weight of the target material....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com