Spinning method for cotton and linen slub yarns

A fancy yarn and slub technology, which is applied in the spinning of cotton-linen slub fancy yarn and the field of ring-spun cotton-linen slub fancy yarn. Problems such as single yarn style

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A spinning method of cotton-linen slub yarn, which comprises drawing cotton roving and linen roving separately, converging and accumulating, twisting and winding to obtain cotton-linen slub yarn;

[0040] The quantitative of cotton roving is 5g / 10m; the raw material of the hemp roving of hemp roving is ramie, and quantitative is 5g / 10m; The set twist of cotton and hemp fancy yarn is unchanged, and the set twist is 300 twist / m;

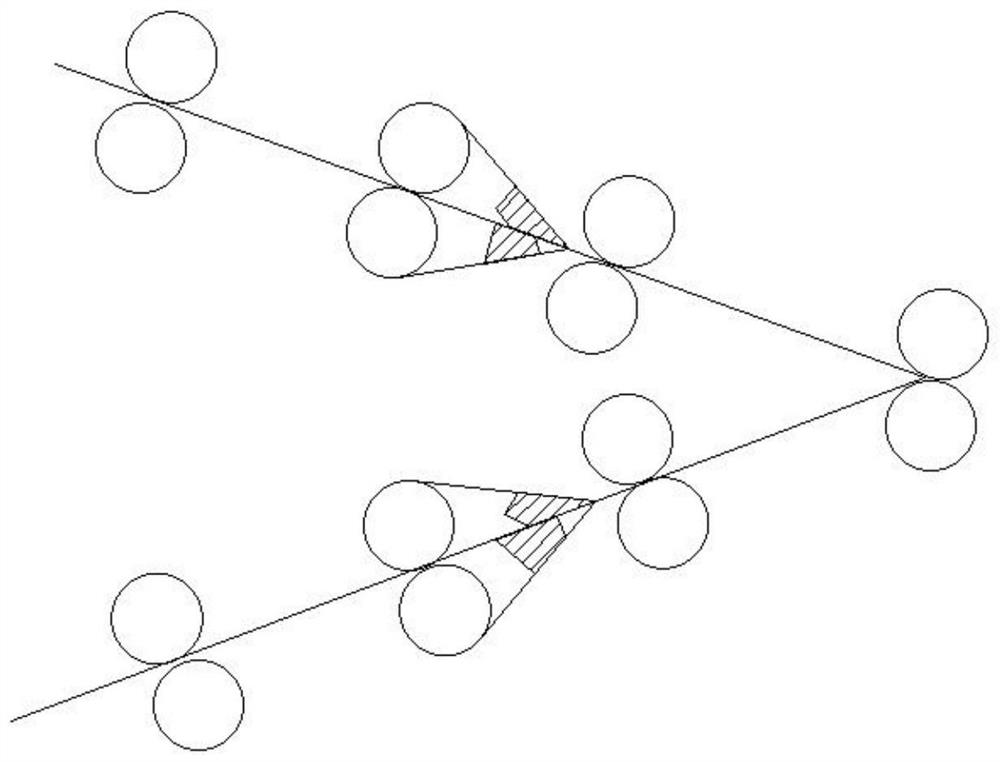

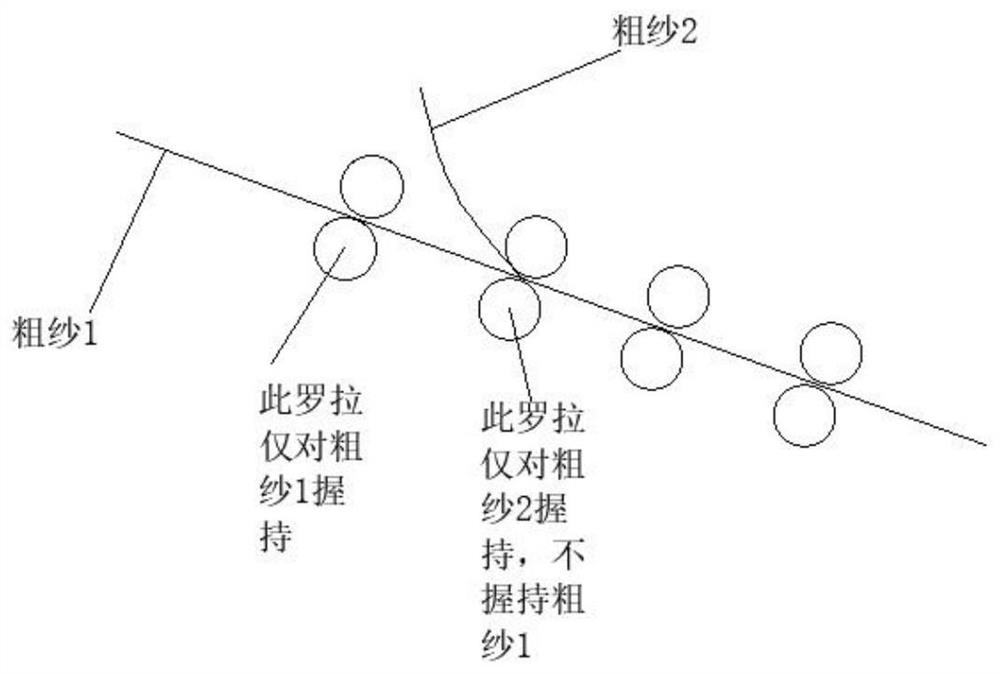

[0041] The drafting of cotton roving is independently drafted by drafting mechanism Ⅰ; the drafting of hemp roving is independently drafted by drafting mechanism Ⅱ; drafting mechanism Ⅰ and drafting mechanism Ⅱ are independently controlled;

[0042] The sum of the feeding weights of cotton roving and hemp roving remains unchanged; the feeding weight ratio of cotton roving and hemp roving changes linearly from 100:0 to 0:100 when transitioning from cotton yarn segment to hemp yarn segment; transitioning from hemp yarn segment to cotton yarn segmen...

Embodiment 2

[0046] A spinning method of cotton-linen slub yarn, which comprises drawing cotton roving and linen roving separately, converging and accumulating, twisting and winding to obtain cotton-linen slub yarn;

[0047] The quantitative of cotton roving is 10g / 10m; the raw material of the hemp roving of hemp roving is hemp, and the quantitative is 10g / 10m; the set twist of cotton twist fancy yarn remains unchanged, and the set twist is 400 twist / m;

[0048] The drafting of cotton roving is independently drafted by drafting mechanism Ⅰ; the drafting of hemp roving is independently drafted by drafting mechanism Ⅱ; drafting mechanism Ⅰ and drafting mechanism Ⅱ are independently controlled;

[0049] The sum of the feeding weights of cotton roving and hemp roving remains unchanged; the feeding weight ratio of cotton roving and hemp roving changes linearly from 100:0 to 0:100 when transitioning from cotton yarn segment to hemp yarn segment; transitioning from hemp yarn segment to cotton yarn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Air permeability | aaaaa | aaaaa |

| Bending length | aaaaa | aaaaa |

| Air permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com