Steam heating device of short fiber production line

A steam heating device and production line technology, applied in the field of polyester staple fiber production, can solve the problems of poor drawing quality of polyester fibers, uneven heating of polyester fibers, poor heating of polyester fibers, etc., to improve drawing quality and improve Heating effect, effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

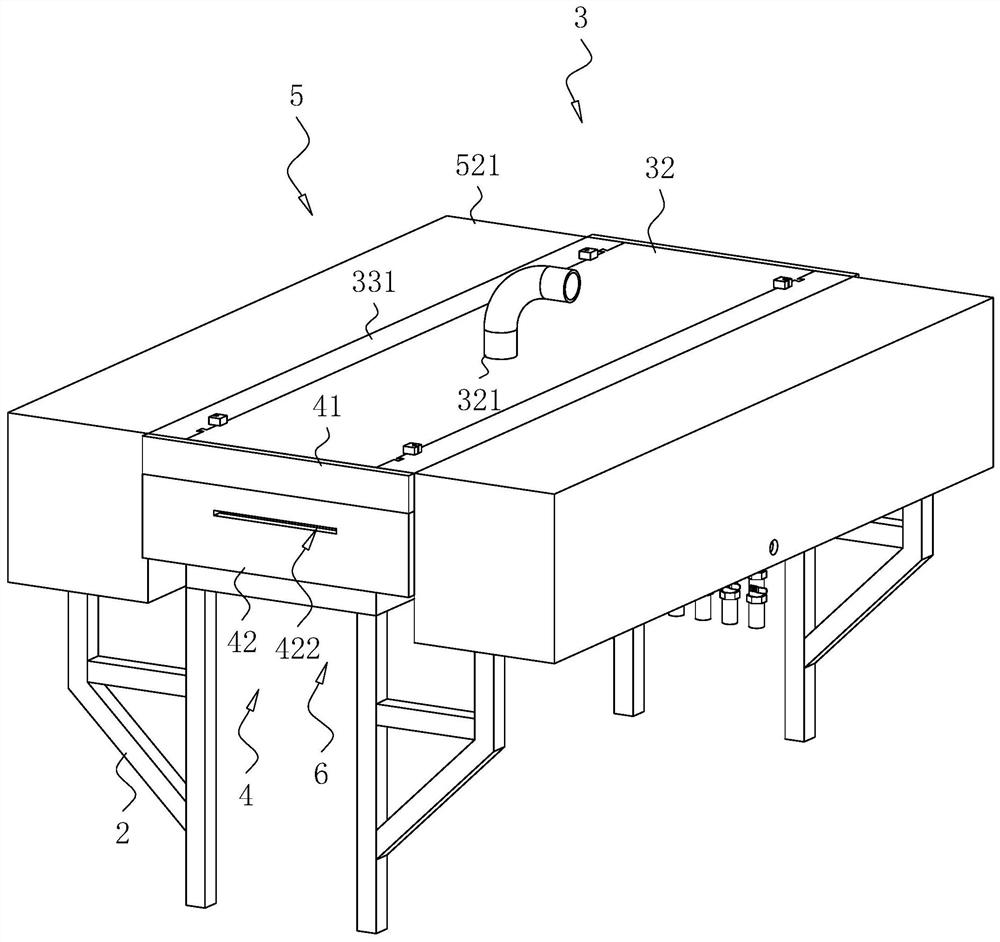

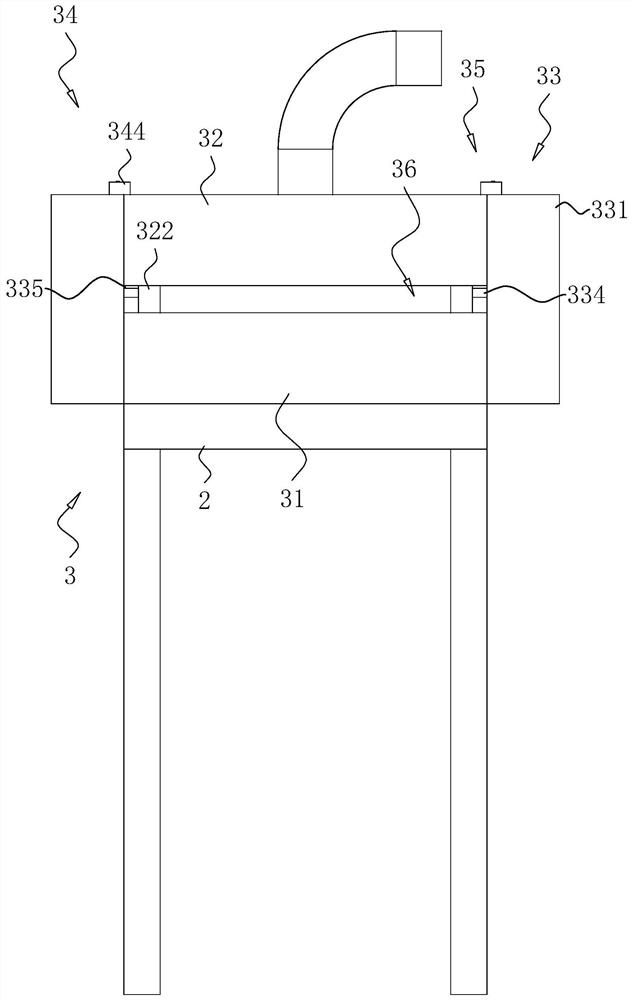

[0038] The following is attached Figure 2-9 The application is described in further detail.

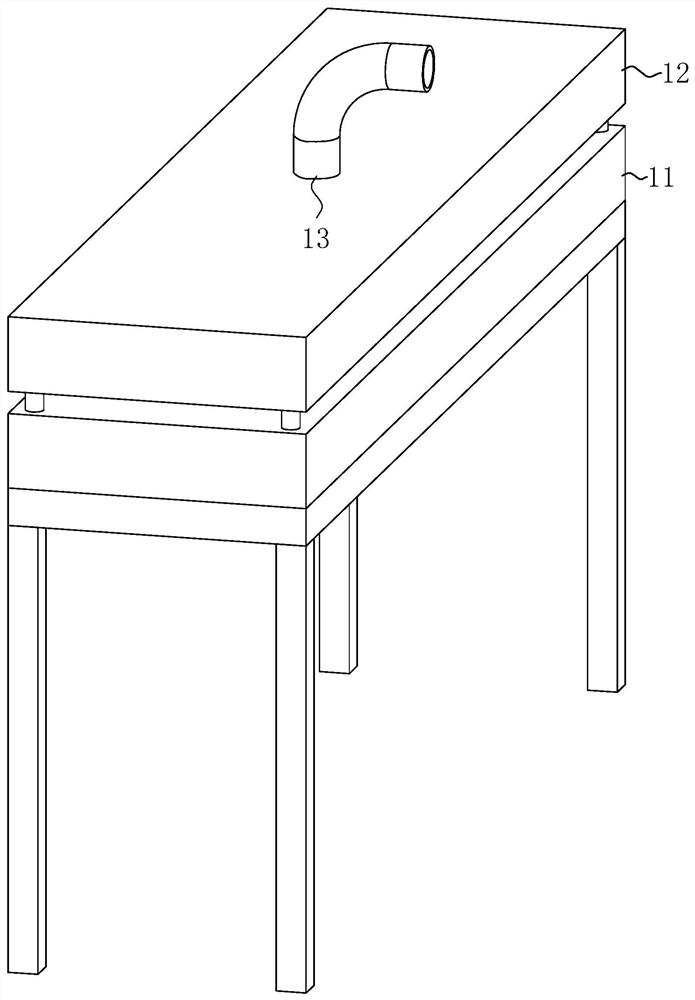

[0039] The embodiment of the present application discloses a steam heating device for a short fiber production line. refer to figure 2A steam heating device for a staple fiber production line includes a support frame 2, a heating box 3 connected to a steam source is arranged on the support frame 2, the steam source provides steam for the heating box 3, polyester fibers pass through the heating box 3, and the polyester fiber One end of the fiber penetration is the penetration end of the heating box 3, and the end of the polyester fiber penetration is the penetration end of the heating box 3. A heat preservation mechanism 5 is provided, and a condensing mechanism 6 is arranged on the lower surface of the heating box 3 .

[0040] The polyester fiber passes through the heating box 3, and the steam heats the polyester fiber to soften the polyester fiber, which is convenient for drawin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com