A kind of spinning method of cotton hemp slub fancy yarn

A fancy yarn and slub technology, which is applied to the spinning of cotton and hemp slub fancy yarns, and the field of ring spinning cotton and hemp slub fancy yarns, and can solve the problem that the properties of hemp cannot be fully utilized, and the cotton and hemp blended Single yarn style and other problems, to achieve the effect of strong three-dimensional fabric style, stable quality and good drafting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A spinning method of cotton-linen slub yarn, which comprises drawing cotton roving and linen roving separately, converging and accumulating, twisting and winding to obtain cotton-linen slub yarn;

[0040] The quantitative of cotton roving is 5g / 10m; the raw material of the hemp roving of hemp roving is ramie, and quantitative is 5g / 10m; The set twist of cotton and hemp fancy yarn is unchanged, and the set twist is 300 twist / m;

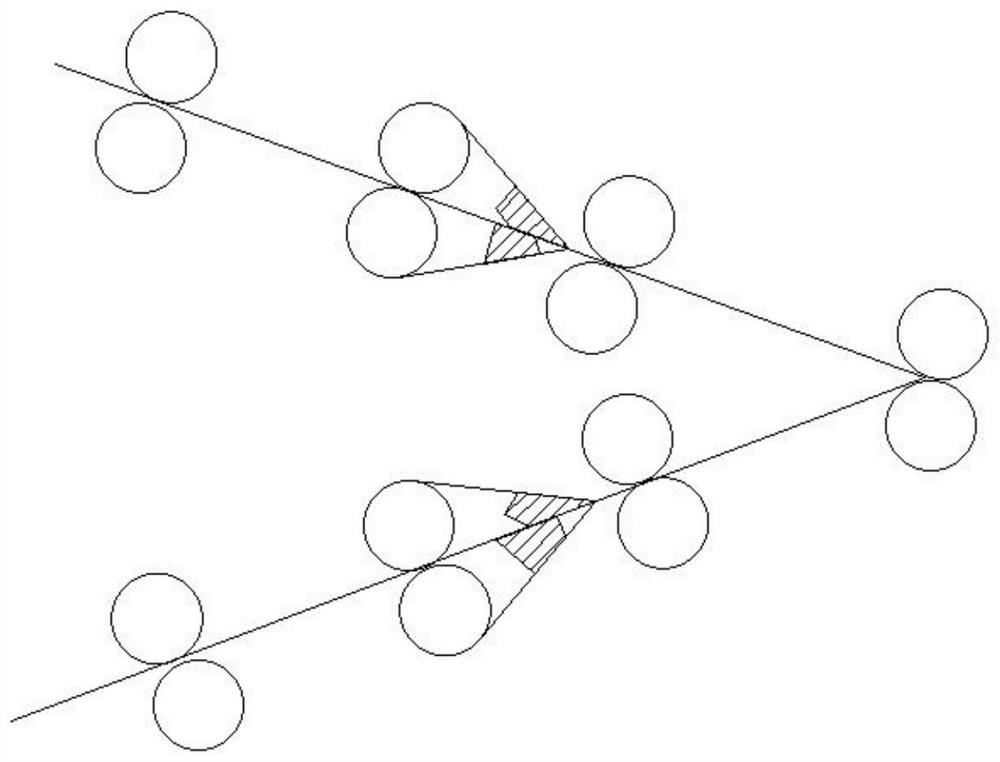

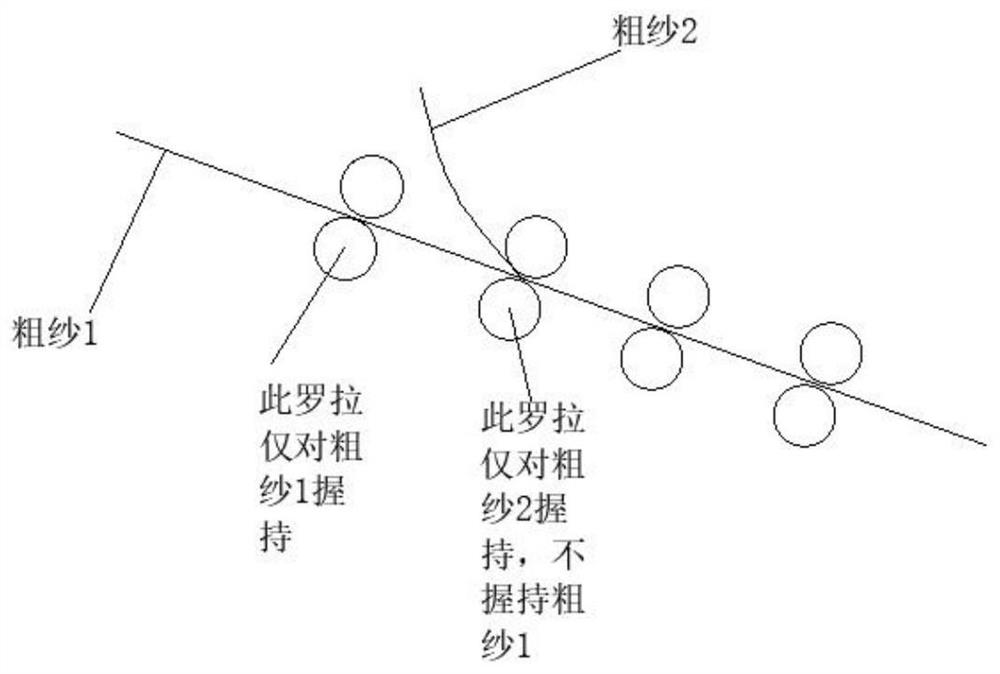

[0041] The drafting of cotton roving is independently drafted by drafting mechanism Ⅰ; the drafting of hemp roving is independently drafted by drafting mechanism Ⅱ; drafting mechanism Ⅰ and drafting mechanism Ⅱ are independently controlled;

[0042] The sum of the feeding weights of cotton roving and hemp roving remains unchanged; the feeding weight ratio of cotton roving and hemp roving changes linearly from 100:0 to 0:100 when transitioning from cotton yarn segment to hemp yarn segment; transitioning from hemp yarn segment to cotton yarn segmen...

Embodiment 2

[0046] A spinning method of cotton-linen slub yarn, which comprises drawing cotton roving and linen roving separately, converging and accumulating, twisting and winding to obtain cotton-linen slub yarn;

[0047] The quantitative of cotton roving is 10g / 10m; the raw material of the hemp roving of hemp roving is hemp, and the quantitative is 10g / 10m; the set twist of cotton twist fancy yarn remains unchanged, and the set twist is 400 twist / m;

[0048] The drafting of cotton roving is independently drafted by drafting mechanism Ⅰ; the drafting of hemp roving is independently drafted by drafting mechanism Ⅱ; drafting mechanism Ⅰ and drafting mechanism Ⅱ are independently controlled;

[0049] The sum of the feeding weights of cotton roving and hemp roving remains unchanged; the feeding weight ratio of cotton roving and hemp roving changes linearly from 100:0 to 0:100 when transitioning from cotton yarn segment to hemp yarn segment; transitioning from hemp yarn segment to cotton yarn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com