Spinning method of cotton and linen fancy yarns

A cotton-linen fancy and fancy yarn technology, which is applied to spinning machines, yarns, textiles and papermaking, can solve the problems that the performance of linen can not be fully utilized, and the style of cotton-linen blended yarn is single, so as to achieve soft hand feeling, The effect of full three-dimensional fabric and good draft quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for spinning cotton-twisted fancy yarns, in which cotton rovings and hemp rovings are drawn separately, converged and gathered, twisted and wound to obtain cotton-twisted fancy yarns;

[0039] Cotton roving quantitative is 5g / 10m; The raw material of the hemp roving of hemp roving is ramie, quantitative is 5g / 10m; The set twist of cotton and hemp fancy yarn is constant, and set twist is 300 twist / m;

[0040] The sum of the feeding weights of cotton roving and hemp roving remains unchanged; the feeding weight ratio of cotton roving and hemp roving changes alternately from 70:30 to 30:70 and then to 70:30, specifically: when the proportion of cotton fiber When linearly increasing, hemp fiber decreases linearly in proportion; when the proportion of cotton fiber decreases linearly, hemp fiber increases linearly in proportion;

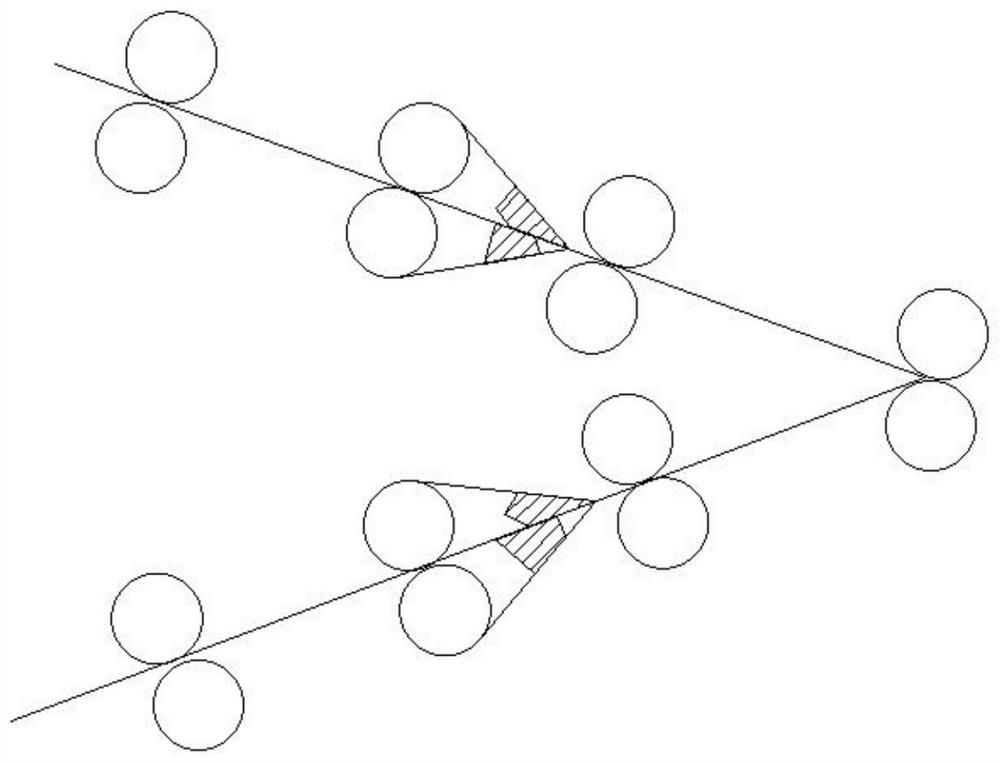

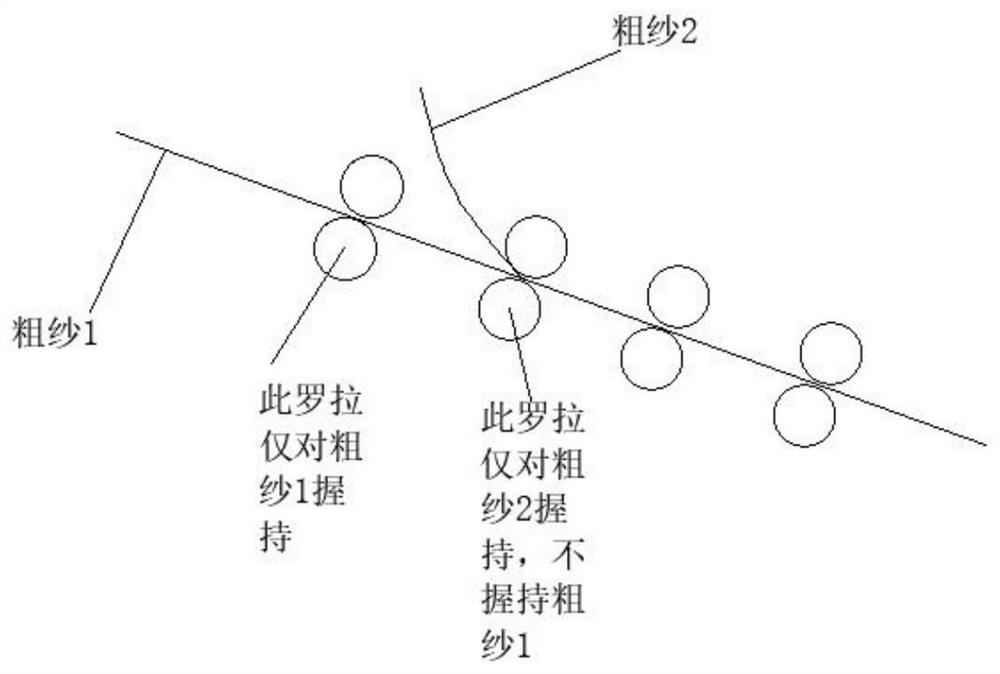

[0041] The drafting of cotton roving is independently drafted by drafting mechanism Ⅰ; the drafting of hemp roving is independently drafted...

Embodiment 2

[0045] A method for spinning cotton-twisted fancy yarns, in which cotton rovings and hemp rovings are drawn separately, converged and gathered, twisted and wound to obtain cotton-twisted fancy yarns;

[0046] The quantitative value of cotton roving is 8g / 10m; the raw material of hemp roving is flax, and the quantitative value is 8g / 10m; the set twist of cotton and hemp fancy yarn remains unchanged, and the set twist is 400 twists / m;

[0047] The sum of the feeding weights of cotton roving and hemp roving remains unchanged; the feeding weight ratio of cotton roving and hemp roving changes alternately from 70:30 to 30:70 and then to 70:30, specifically: when the proportion of cotton fiber When linearly increasing, hemp fiber decreases linearly in proportion; when the proportion of cotton fiber decreases linearly, hemp fiber increases linearly in proportion;

[0048] The drafting of cotton roving is independently drafted by drafting mechanism Ⅰ; the drafting of hemp roving is ind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| drape coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com