Synchronous controlling method for main transmission equipment of terylene short fibre post-treatment combination machine production line

A technology of synchronous control and polyester staple fiber, applied in the direction of motor speed or torque control, control system, electrical program control, etc., can solve the problems that it is difficult to guarantee the draft ratio and the synchronous performance of the transmission motor, etc., to achieve Improve drawing quality, ensure synchronous operation and reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

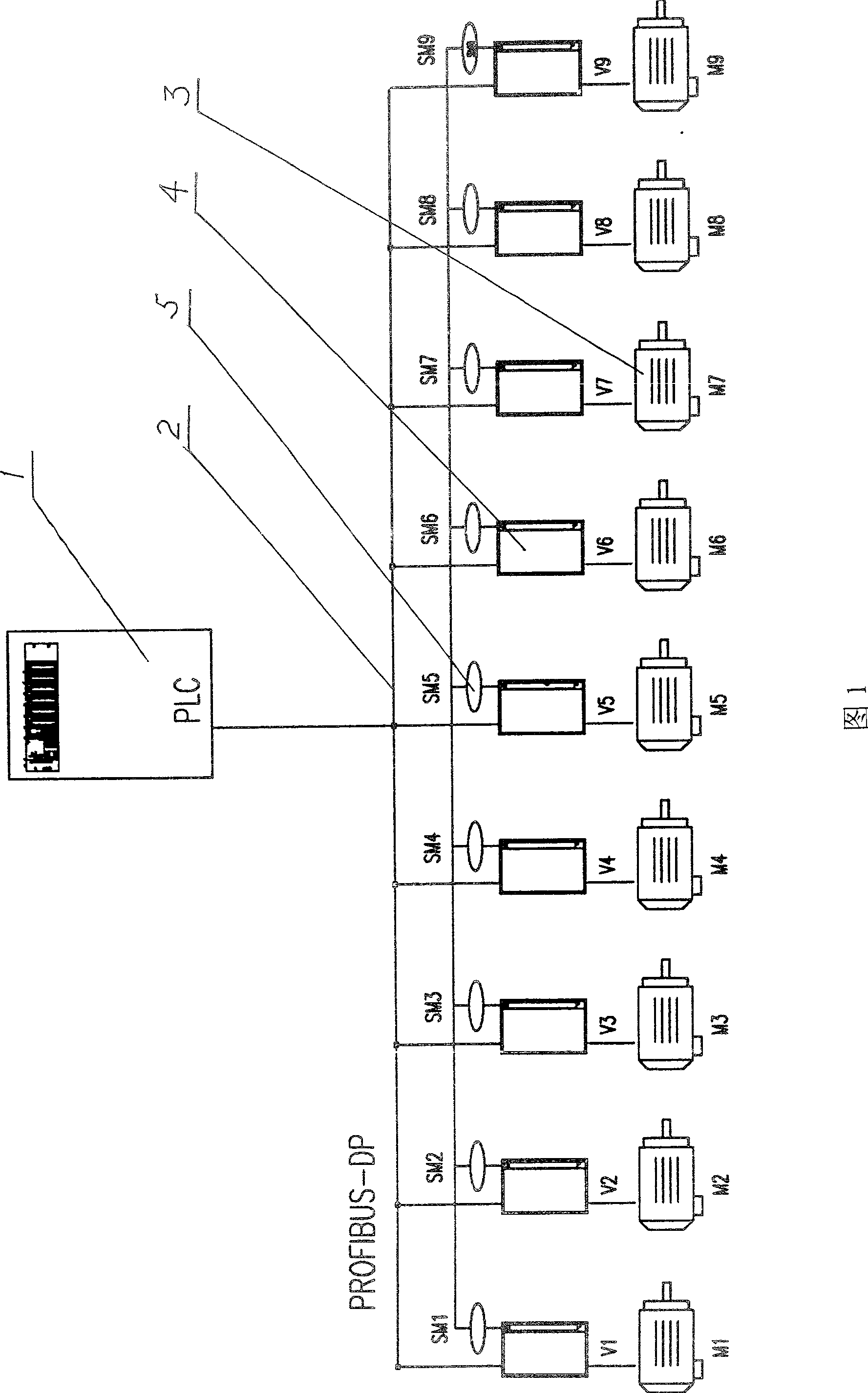

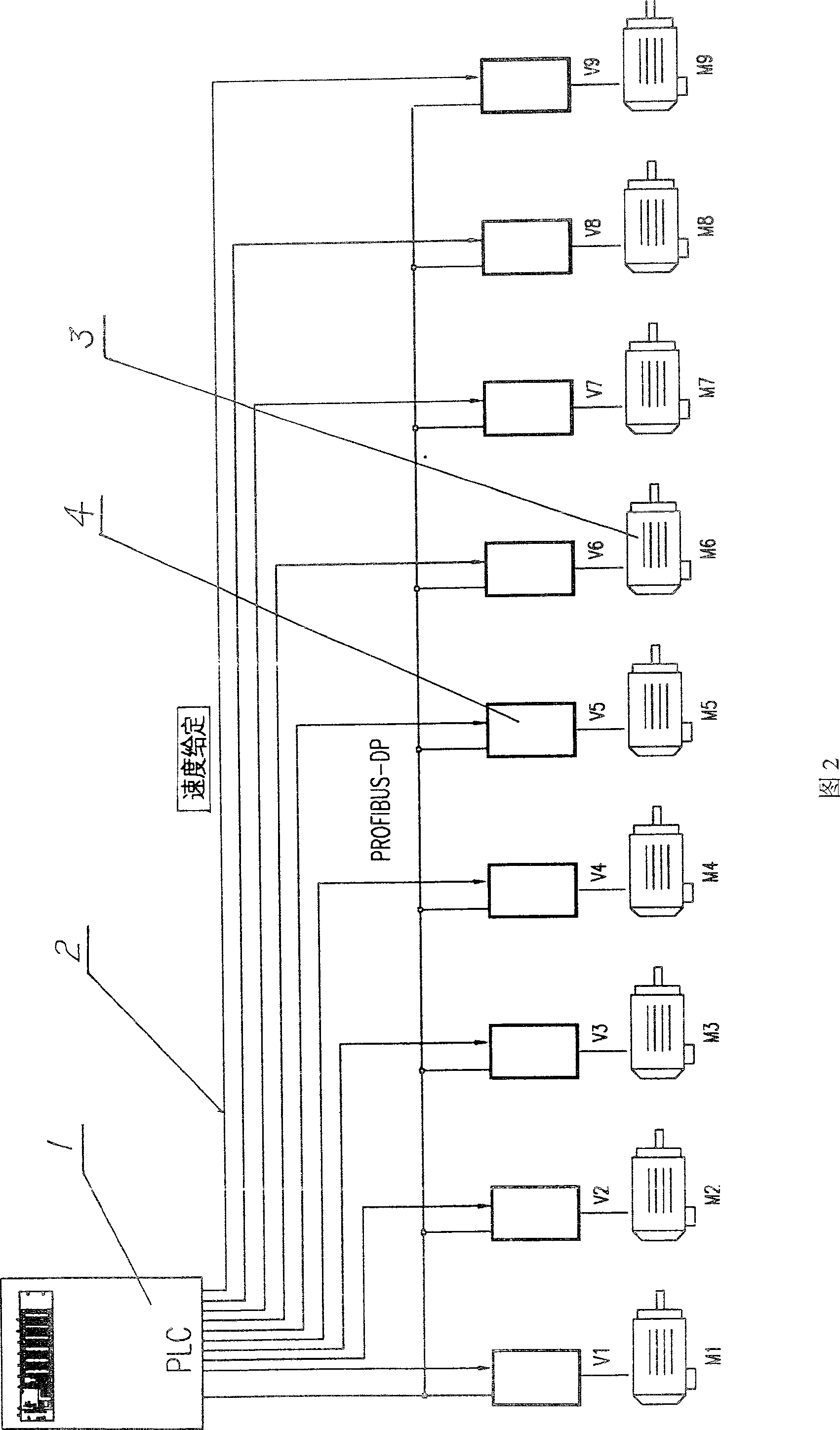

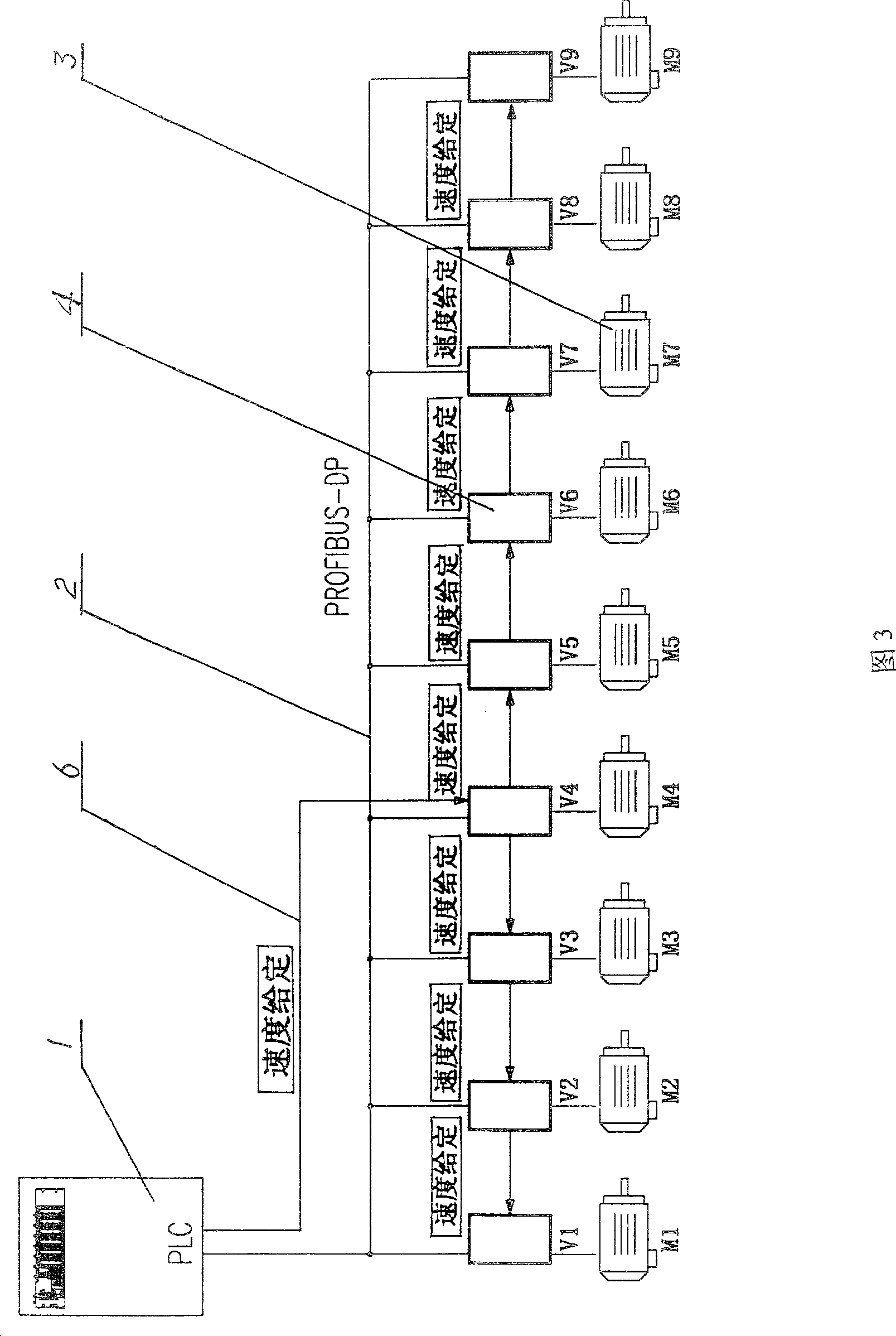

[0023] As shown in Figure 3, it is a synchronous control method structural diagram of the main transmission equipment of the polyester staple fiber post-processing combined machine production line of the present invention, and the main transmission equipment of the polyester staple fiber post-processing combined machine production line is controlled by a programmable controller 1 (PLC ) through the PROFIBUS-DP field bus network 2 to connect with the inverters 4 (V1-V9) connected to 9 main drive motors 3 (M1-M9) in one-to-one correspondence, and each main drive motor 3 and inverter 4 form a The transmission device and the programmable controller 1PLC are connected to the inverter 4 with the highest power among them through the PROFIBUS-DP field network bus 6, and the inverter 4 with the highest power among them is connected in series with other inverters.

[0024] Such as Figure 4 As shown, it is a program flow chart of the synchronous control method of the present invention. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com