Condensate pump arrangement method

A technology of condensate pump and arrangement method, applied in steam engine installations, machines/engines, mechanical equipment, etc., can solve problems such as difficulty in sampling negative pressure water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

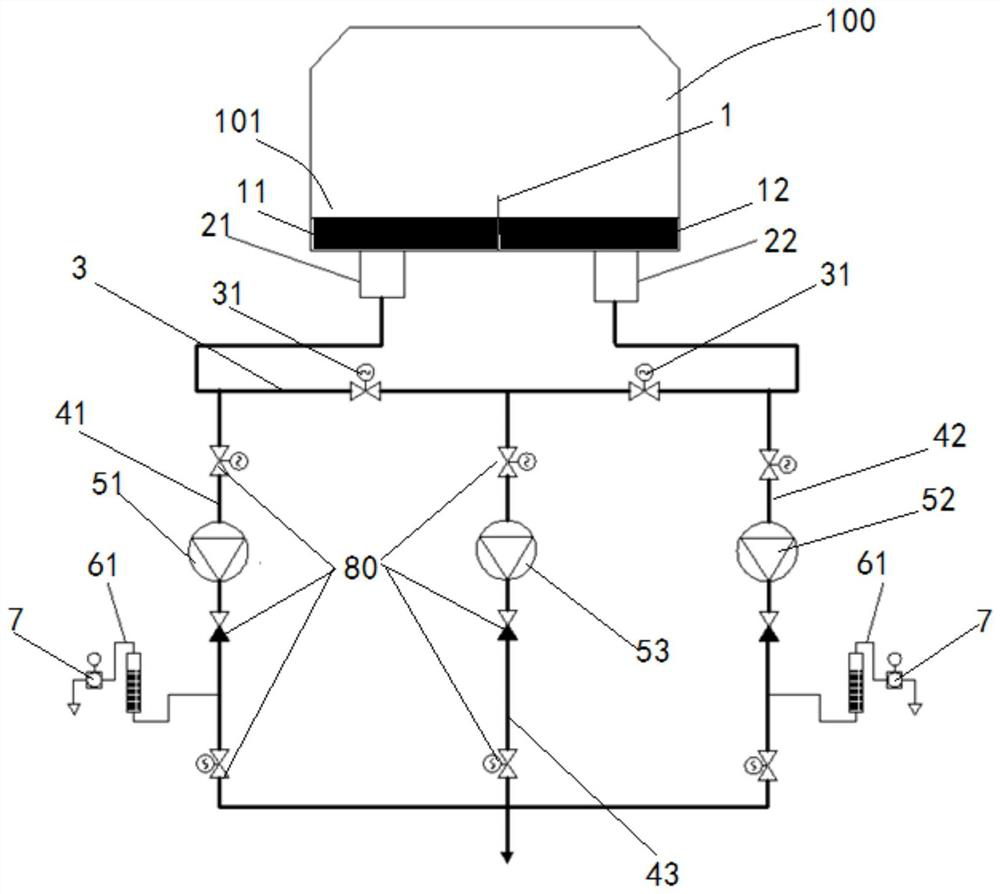

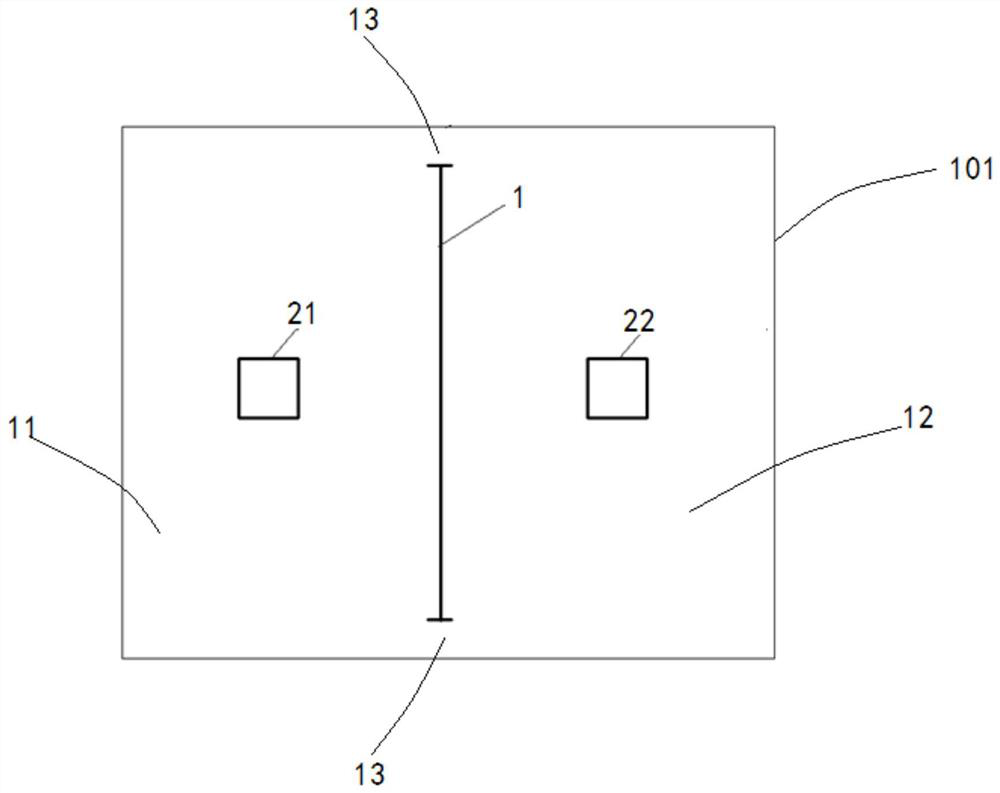

[0038]SeeFigure 1 ~ 2A condensate pump arrangement method provided by the present invention includes: a partition plate 1 is disposed vertically in the inner surface of the bottom plate of the condenser 100, the separator 1 to condense the condensed water cavity in the hot well 101 The first condensate cavity 11 and the second condensate cavity 12, the first condensate cavity 11, and the second condensate cavity 12 are communicated between the first condensate cavity 12; in the hot well 101 corresponding to the first condensate cavity 11. The outer surface of the bottom plate is provided with a first collector 21, and the inlet end of the first collector 21 communicates with the inner side of the first condensate chamber 11, outside the bottom plate corresponding to the hot well 101 of the second condensate cavity 12. A second collector 22 is provided with an inner side of the second collector 22 in the inner side of the second condensate chamber 12; the water end of the first colle...

Embodiment 2

[0060]The sides of the partition plate 1 have a gap 13 between the adjacent side walls of the hot well 101, and the first condensed water chamber 11 and the second condensate cavity 12 are passed through the The gap 13 forms a communication.

[0061]The gap 13 is provided on both sides to ensure stability of the first condensate cavity 11 and the second condensate cavity 12, ensuring that the first condensate cavity 11 and the second condensate cavity 12 are consistent.

[0062]The rest is the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com