Method for detecting pretightening force of high-strength bolt

A technology of high-strength bolts and detection methods, applied in force/torque/work measuring instruments, measuring torque/torsional force during tightening, measuring devices, etc., can solve problems such as difficulty in use, wave speed error, etc. The effect of stable excitation frequency and stable measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further specifically described below in conjunction with the accompanying drawings and embodiments.

[0032] See Figure 1~ Figure 8 , the detection method of high-strength bolt preload provided by the invention specifically comprises the following steps:

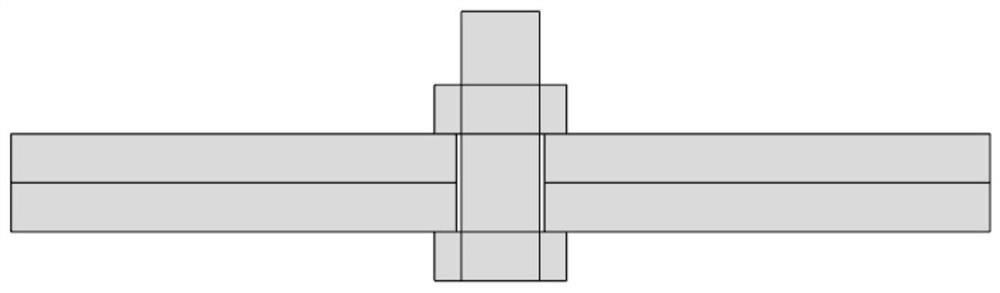

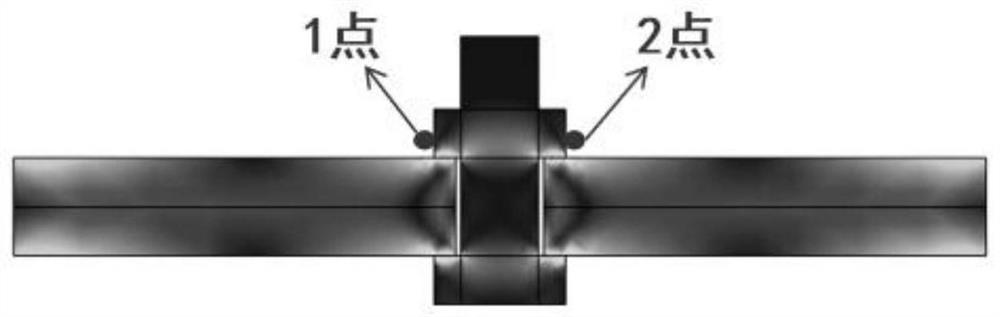

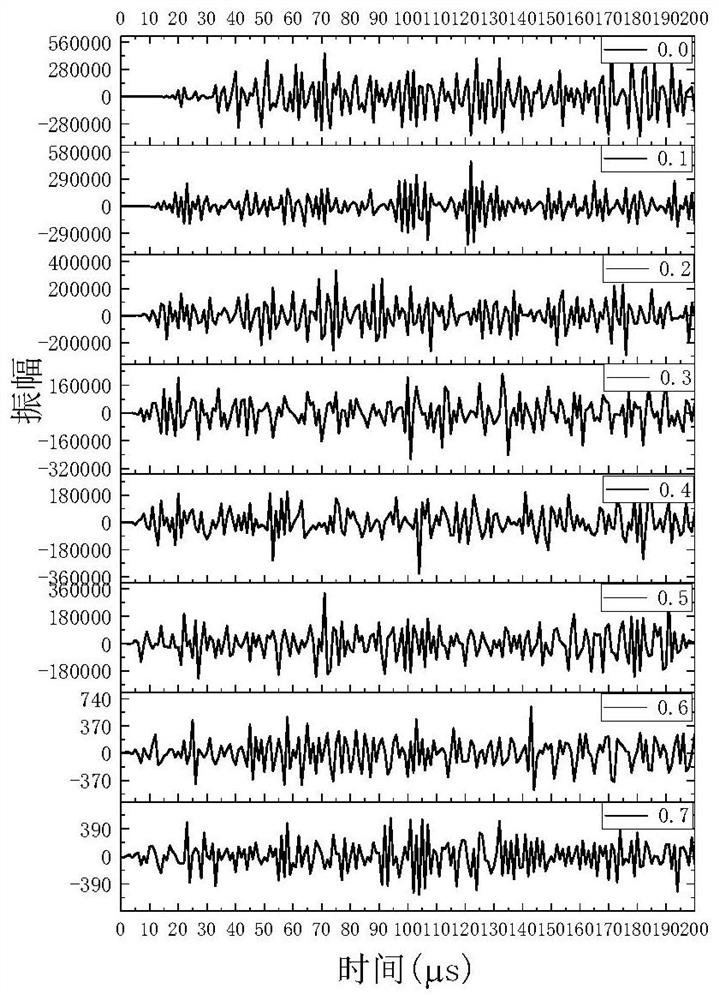

[0033] (1) Select a model with a bolt diameter of 16mm, according to the actual situation of high-strength bolts in steel structure engineering (such as Figure 1a Shown) Set the elastic modulus (Ε), density (ρ), Poisson's ratio (μ) of the relevant material, and establish high-strength bolts at different preloads in COMSOL Multiphysics (that is, the preload reaches the high-strength bolt 0, 10%, 20%, 30%, 40%, 50%, 60%, 70% of the tensile strength design value) when the finite element model, using material parameters as shown in Table 1:

[0034] Table 1

[0035] Elastic modulus (GPa) Density(kg / m3) Poisson's ratio steel plate 200 7850 0.3 bolt 209 7850 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com