Fabricated steel structure flower basket structure

A steel structure and assembly technology, which is applied in the direction of building construction, construction, and building material processing, can solve problems such as time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

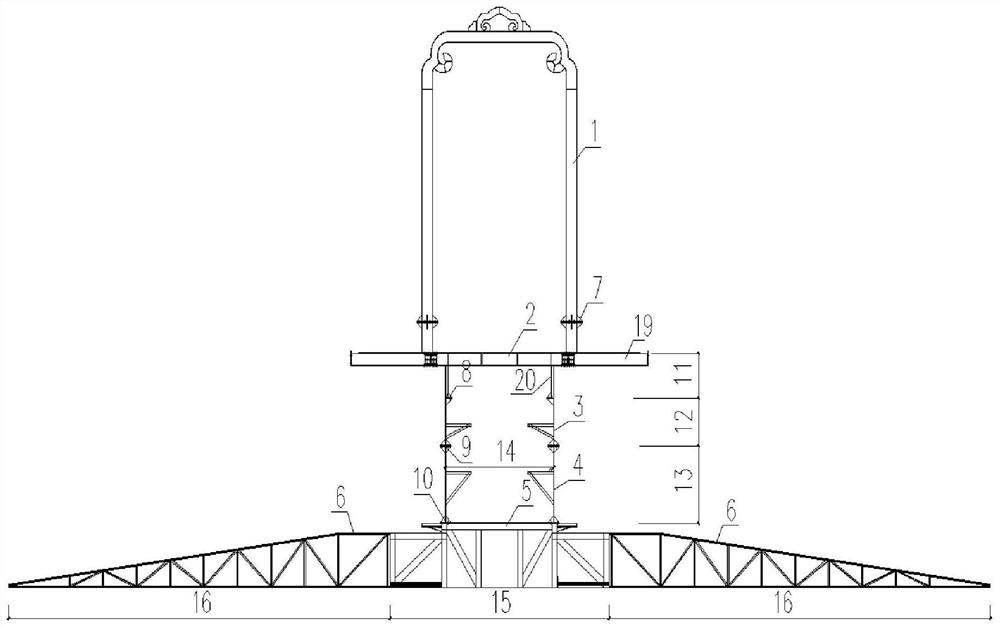

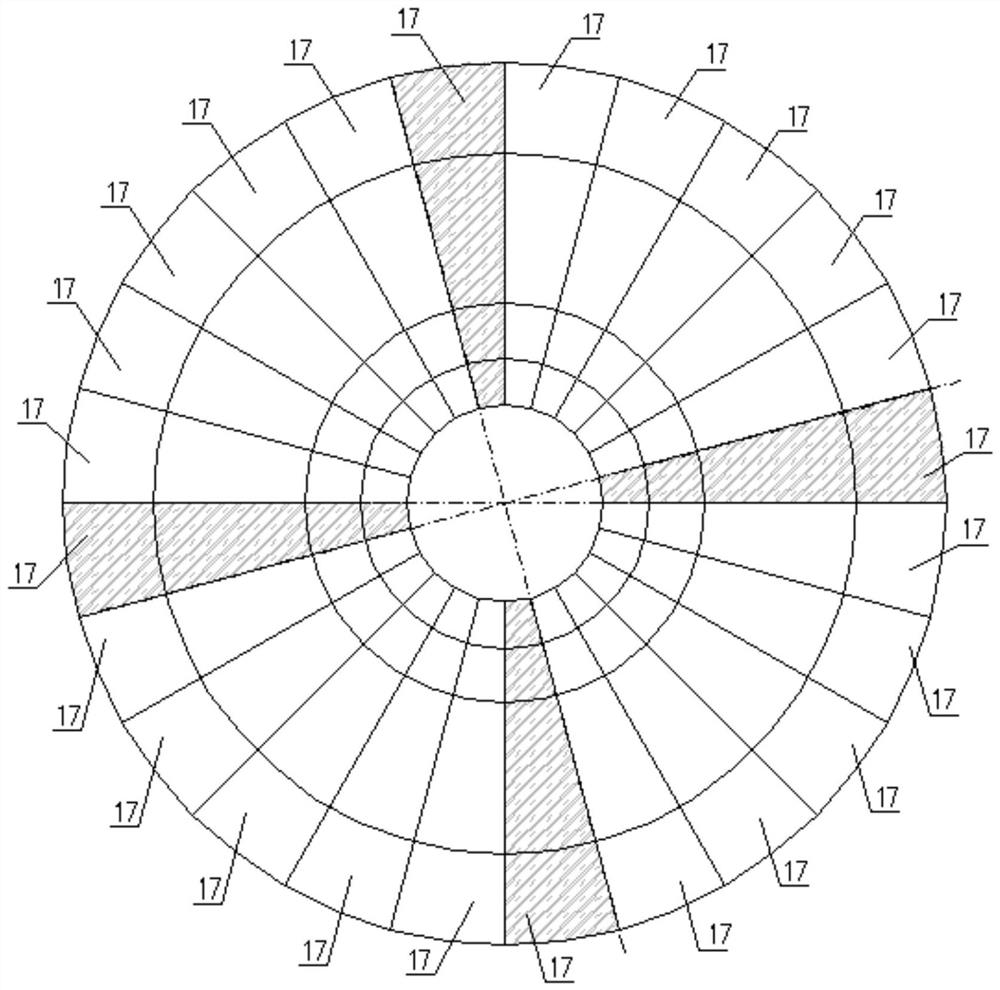

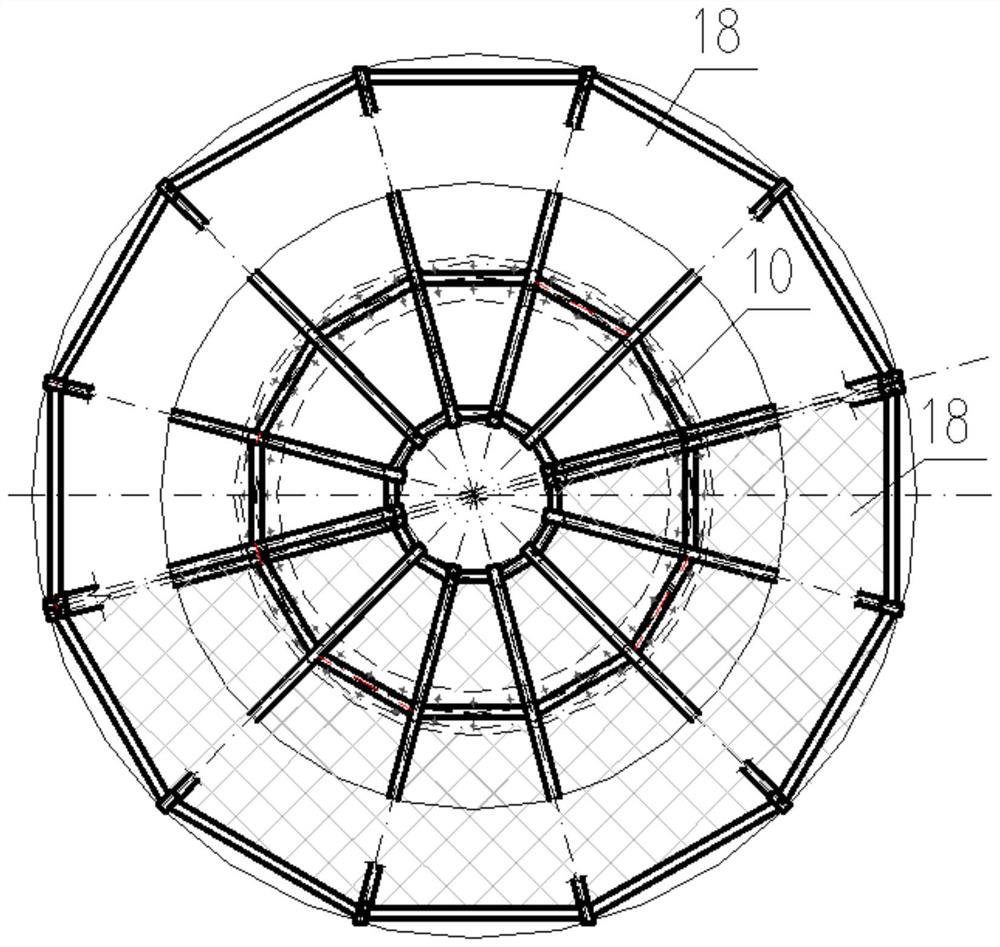

[0014] The present invention includes a basket core 1, a basket plate 2, an upper supporting basket tube 3, a lower supporting basket tube 4, a basket supporting frame 5, a flower bracket 6, a connection node 7 between the basket core and the basket plate, and the basket plate and the upper supporting basket tube Connection node 8, upper support basket and lower support basket connection node 9, lower support basket and basket support frame connection node 10, blue plate height 11, upper support basket height 12, lower support basket height 13, basket Tube diameter 14, basket support frame diameter 15, flower bracket length 16, flower bracket slices 17, basket support frame slices 18, steel platform installed inside the basket 19, basket inner tube 20, basket support steel The beam 21, the connecting beam 22 between the basket supporting steel beams, and the sub-block 23 for making the basket.

[0015] Before the on-site installation, the basket core 1, the basket plate 2, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com