Prefabricated and assembled fish belly corrugated steel web body prestressed steel-concrete composite simply supported girder bridge and its construction method

A corrugated steel web, prefabricated assembly technology, applied in the direction of erecting/assembling bridges, bridges, bridge materials, etc., can solve the problems of durability restricting wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

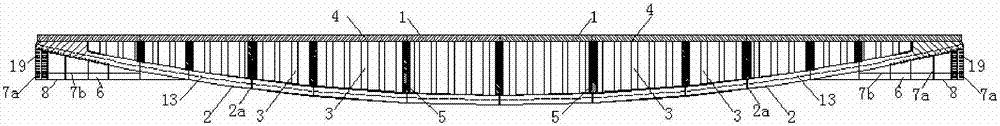

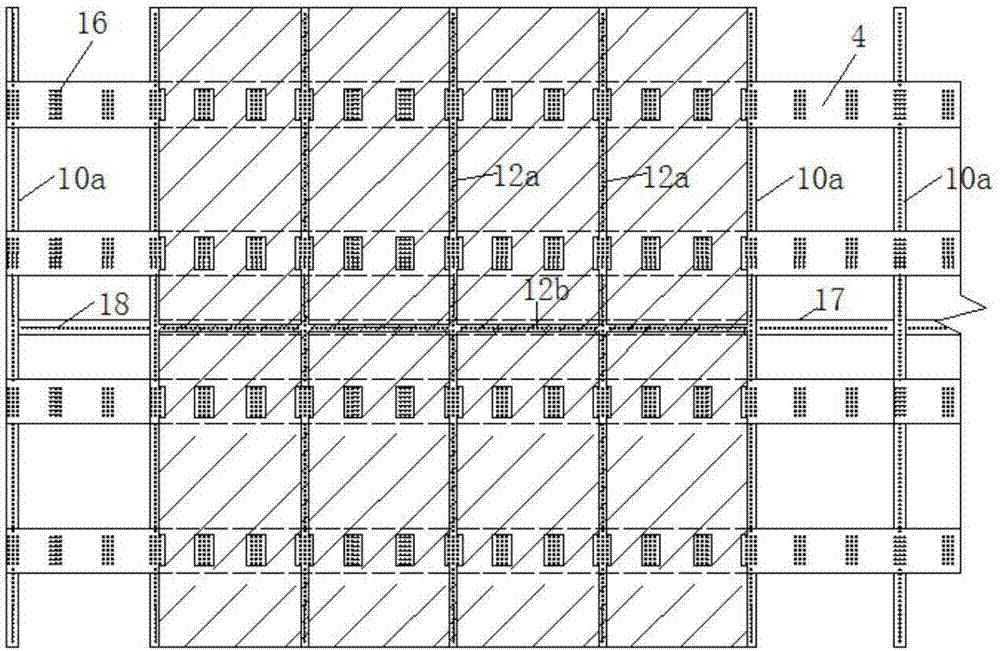

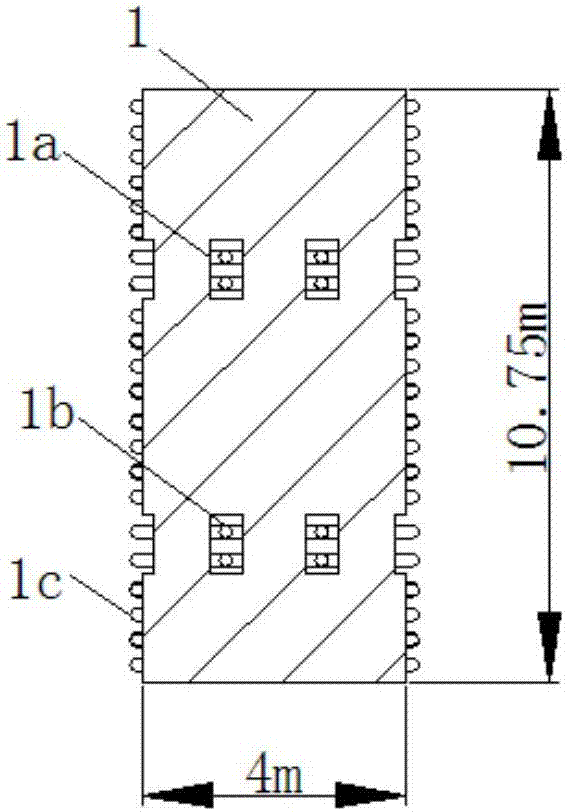

[0035] 1. The basic structure of prefabricated and assembled fish-belly corrugated steel web prestressed steel-concrete composite simply supported beam bridge

[0036] The prefabricated fish-belly corrugated steel web girder and the prefabricated concrete bridge deck are adopted, the lower flange of the fish-belly corrugated steel web girder adopts steel-clad concrete members, and the concrete of the lower flange ladle-clad concrete members is tensioned and prestressed. (See figure 1 ), its rise-span ratio is controlled between 1 / 15-1 / 20, and the fish belly line of the lower flange is a catenary or parabola; Between 2 / 3. The length control of the web along the main girder near the support area is determined according to the design shear force of the main girder, and the shear force near the support should satisfy:

[0037] V≤t f h f f v +0.75A g f g tanθ+A s f s tanθ

[0038] In the formula, V is the design shear force, tf is the thickness of the web, hf is the heigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com