Lateral pushing type double-layer conveying system for butt joint of vertical storehouses

A technology of double-layer conveying and vertical warehouse, applied in the field of warehousing and logistics, can solve the problems of increased labor cost and poor safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

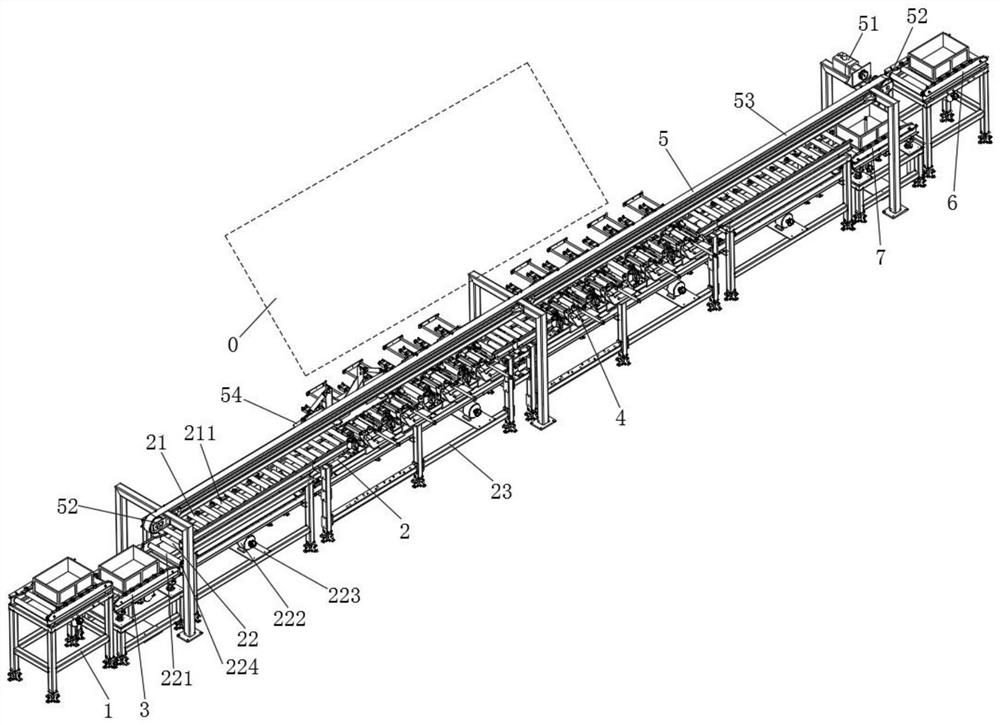

[0065] Such as figure 1 As shown, a side-push double-layer conveying system for docking of vertical warehouses, including

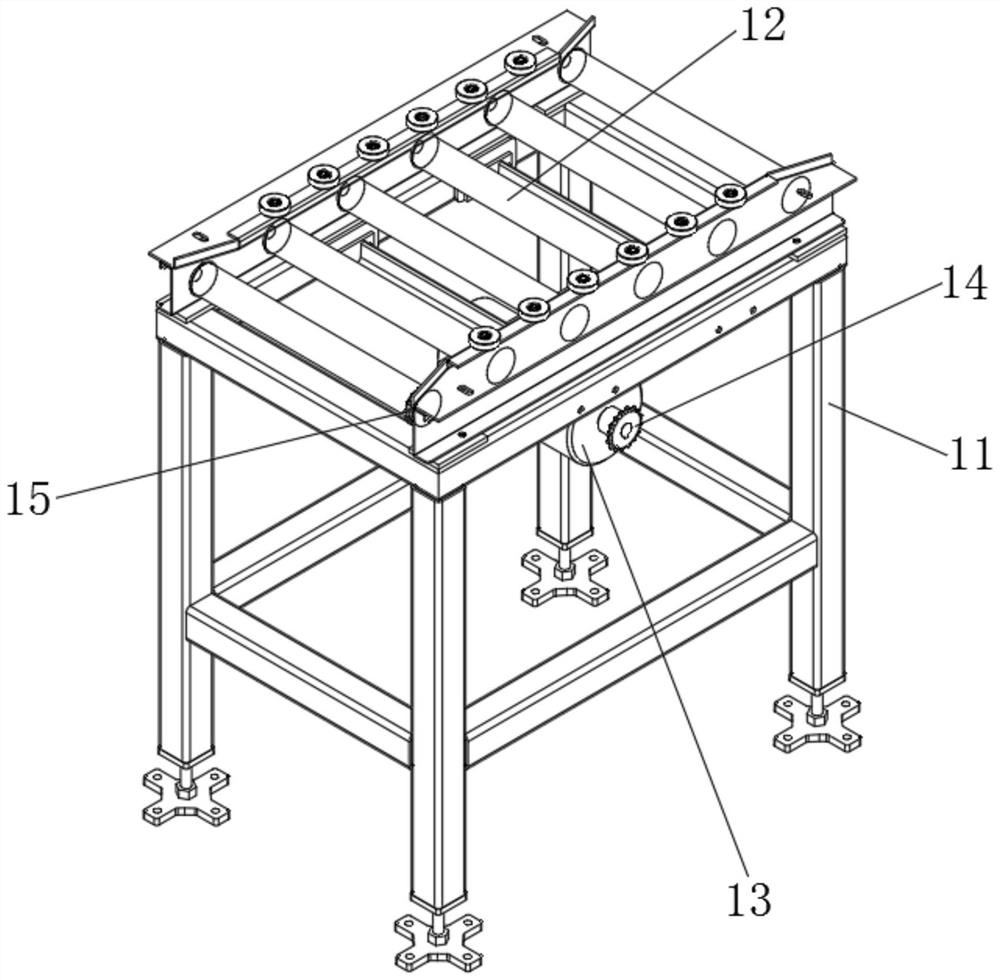

[0066] Inbound conveyor line 1 for inbound delivery of goods;

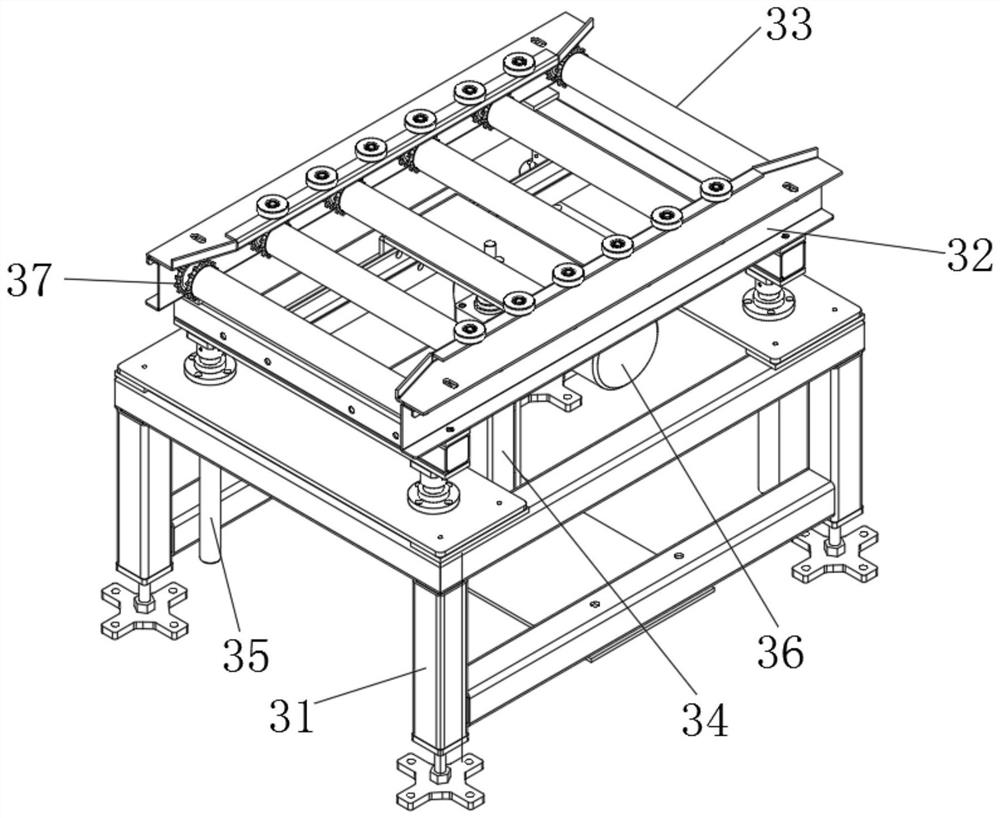

[0067] A double-layer conveyor line 2 for docking with the vertical warehouse 0. The double-layer conveyor line 2 includes two rows of upper-layer conveyor lines 21 and lower-layer conveyor lines 22 arranged in parallel;

[0068] The first lifting and docking conveyor line 3 used to connect the storage conveyor line 1 and the double-layer conveyor line 2, the first lift and docking conveyor line 3 realizes the connection with the storage conveyor line 1 or the upper conveyor line 21 or the lower conveyor line 22 docking;

[0069] The middle part of the upper conveying line 21 is provided with several pushing mechanisms 4 for pushing goods into the vertical warehouse 0 along the conveying direction.

[0070] Wherein, the storage conveying line 1, the upper conveying line 21, and the lower c...

Embodiment 2

[0110] On the basis of Embodiment 1, the end of the double-layer conveying line 2 away from the warehouse-in conveying line 1 is provided with a warehouse-out conveying line 6; The conveying line 7, the second lifting and docking conveying line 7 realizes the docking with the outbound conveying line 6 or the upper conveying line 21 or the lower conveying line 22 through lifting;

[0111] The structure of the outbound conveying line 6 is the same as that of the inbound conveying line 1;

[0112] The structure of the second lifting and docking conveyor line 7 is the same as that of the first lifting and docking conveyor line 3 .

[0113] The vertical warehouse docking in embodiment 2 can be matched with the existing pushing device in the vertical warehouse with the side-push type double-layer conveying system, which can realize the delivery of goods, as follows;

[0114] The goods in the vertical warehouse 0 are pushed to the upper conveying line 21 by the internal pushing devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com