Conversion lens, interchangeable lens, and image capturing apparatus

A technology for converting lenses and lenses, applied in installation, instruments, optics, etc., can solve problems such as difficult to convert lenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

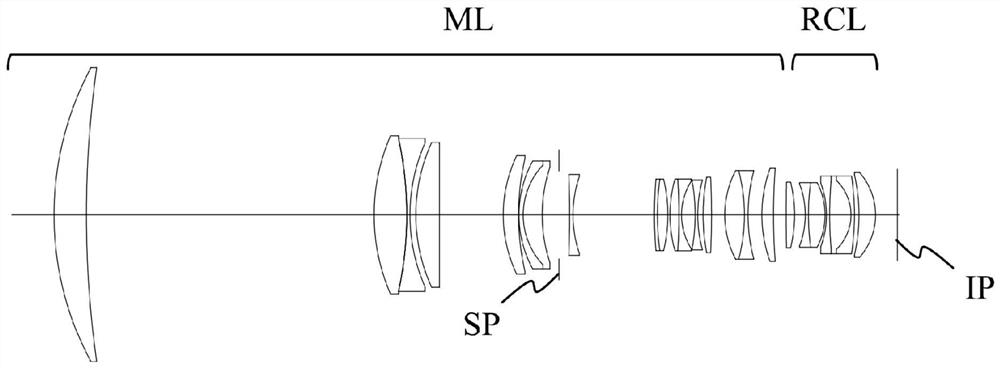

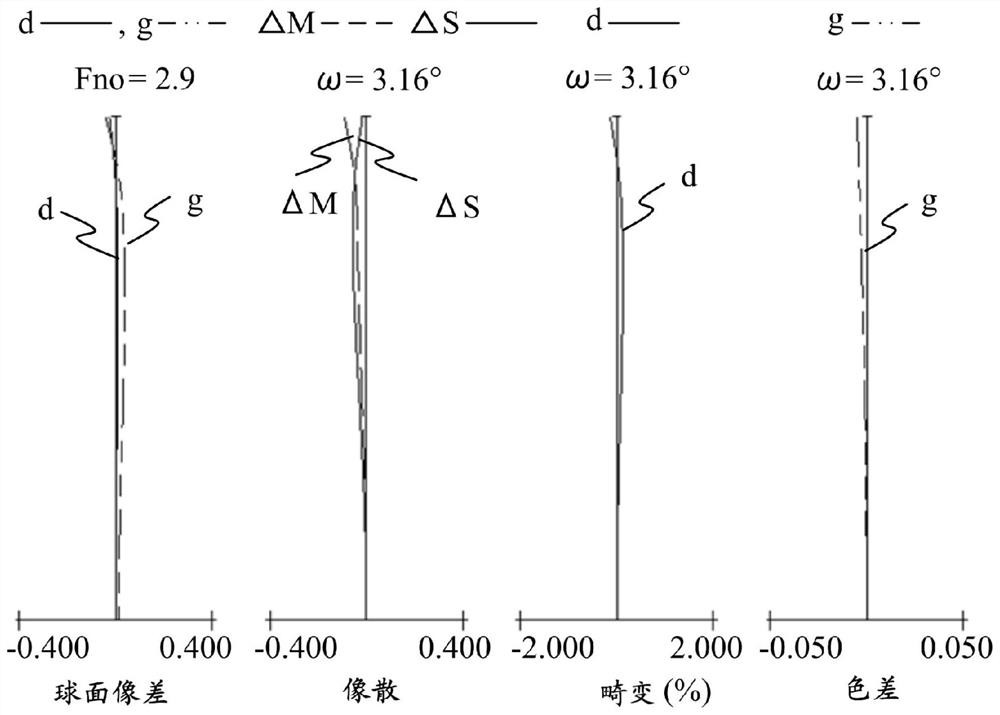

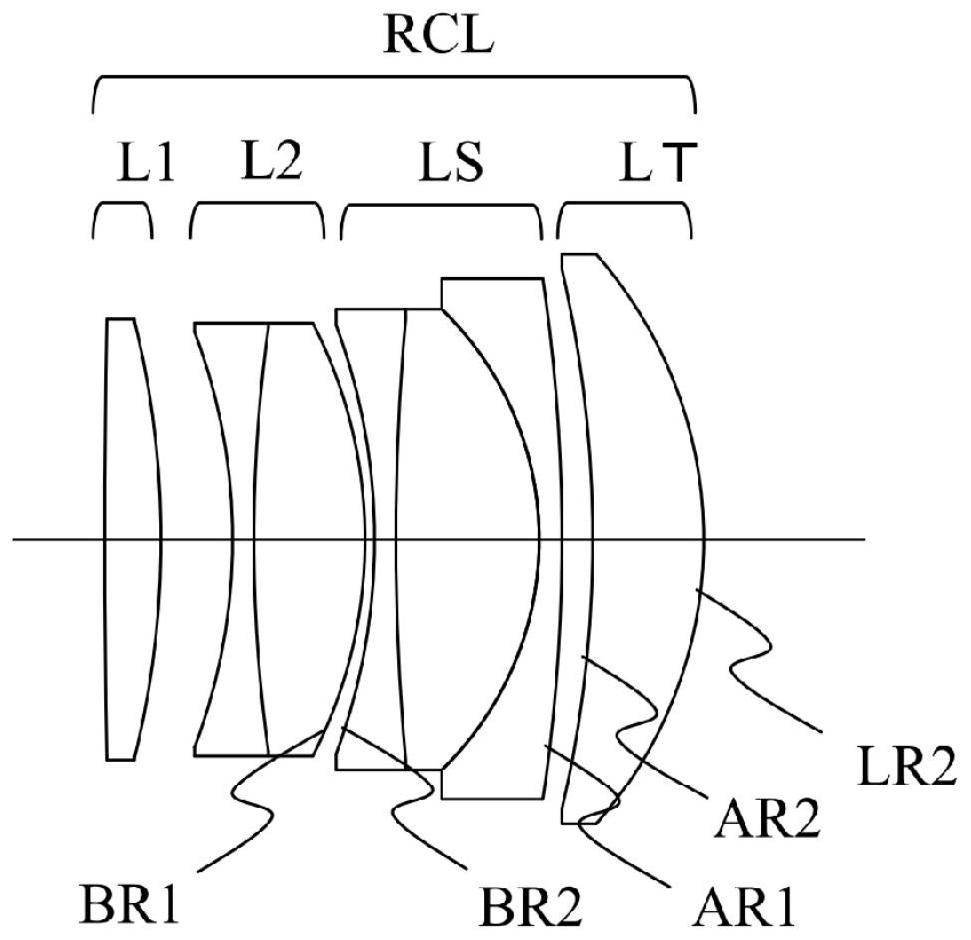

[0119] image 3 is a sectional view of the conversion lens RCL according to the first embodiment. Figure 4 is an aberration diagram of the conversion lens RCL according to the first embodiment when focusing on an object at infinity when disposed on the image side of the main lens ML.

[0120] In conversion lens RCL according to the first embodiment, first lens element L1 is a positive single lens disposed closest to the object side in conversion lens RCL. The second lens element L2 is a cemented lens in which two lenses of a negative lens and a positive lens are sequentially cemented from the object side to the image side. Lens element LT is a positive single lens disposed closest to the image side in conversion lens RCL, and lens element LS is a cemented lens in which three lenses of a negative lens, a positive lens, and a negative lens are sequentially cemented from the object side.

no. 2 example

[0122] Figure 5 is a sectional view of the conversion lens RCL according to the second embodiment. Image 6 is an aberration diagram of the conversion lens RCL according to the second embodiment when focusing on an object at infinity when disposed on the image side of the main lens ML.

[0123] In conversion lens RCL according to the second embodiment, first lens element L1 is a positive single lens disposed closest to the object side in conversion lens RCL. The second lens element L2 is a cemented lens in which two lenses of a negative lens and a positive lens are sequentially cemented from the object side to the image side. Lens element LT is a positive single lens disposed closest to the image side in conversion lens RCL, and lens element LS is a cemented lens in which three lenses of a negative lens, a positive lens, and a negative lens are sequentially cemented from the object side.

no. 3 example

[0125] Figure 7 is a sectional view of the conversion lens RCL according to the third embodiment. Figure 8 is an aberration diagram of the conversion lens RCL according to the third embodiment when focusing on an object at infinity when disposed on the image side of the main lens ML.

[0126] In conversion lens RCL according to the third embodiment, first lens element L1 is a positive single lens disposed closest to the object side in conversion lens RCL. The second lens element L2 is a cemented lens in which three lenses of a negative lens, a positive lens, and a negative lens are sequentially cemented from the object side to the image side. Lens element LT is a positive single lens disposed closest to the image side in conversion lens RCL, and lens element LS is a cemented lens in which two lenses of a positive lens and a negative lens are sequentially cemented from the object side.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap