An inspection well lifting construction structure

An inspection well and anti-sinking technology, applied in the field of inspection wells, can solve problems such as subsidence, reduce the probability of subsidence, improve the convenience of use, and improve the effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following is attached Figure 1-5 The application is described in further detail.

[0038] The embodiment of the present application discloses a lifting construction structure for an inspection well.

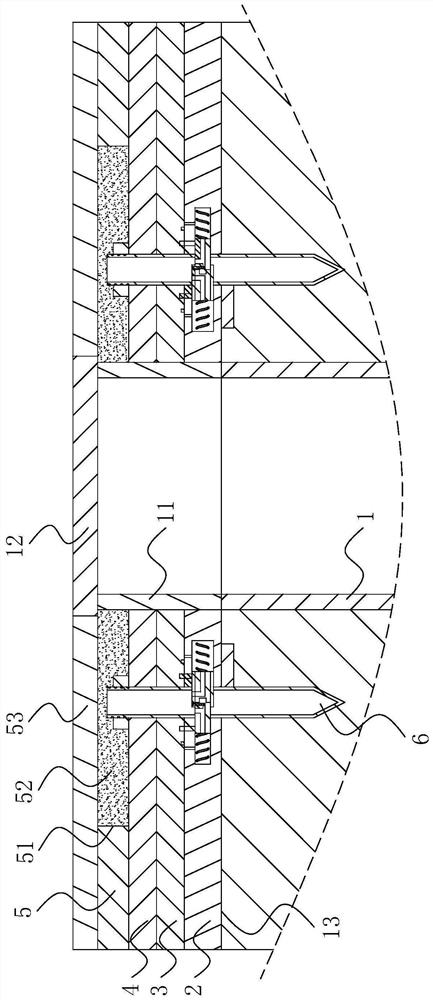

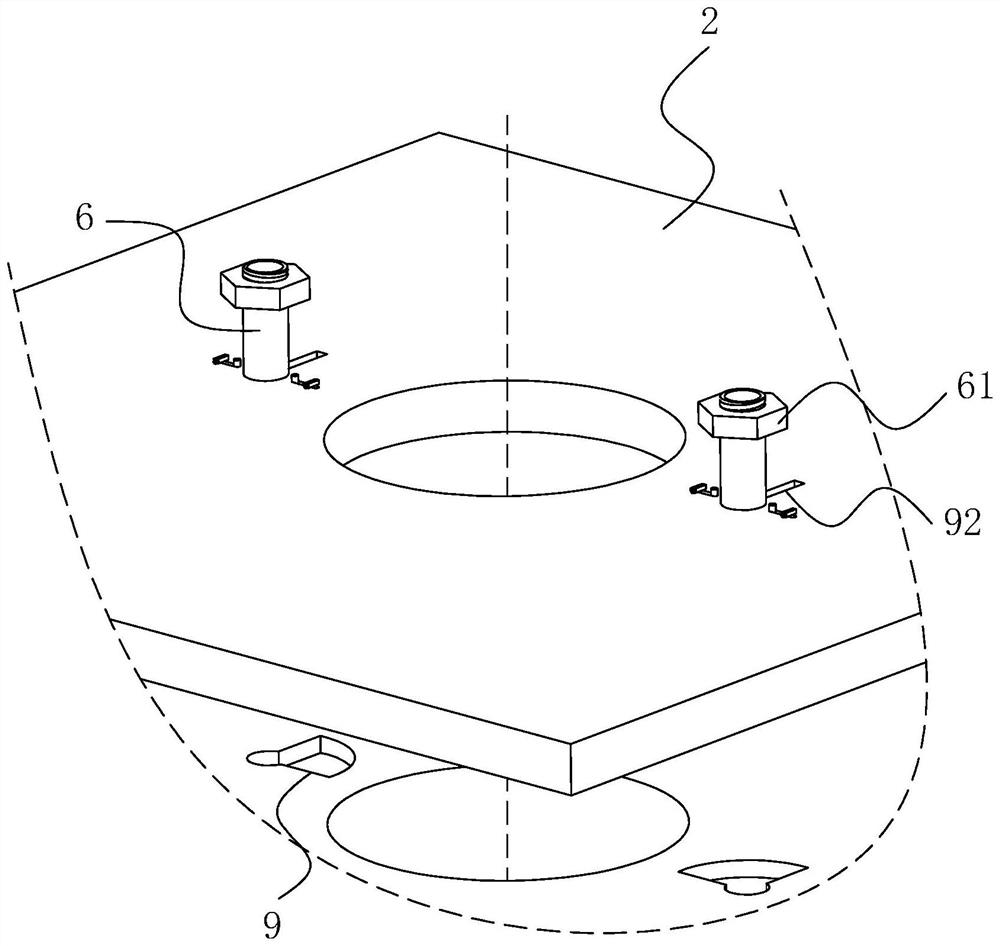

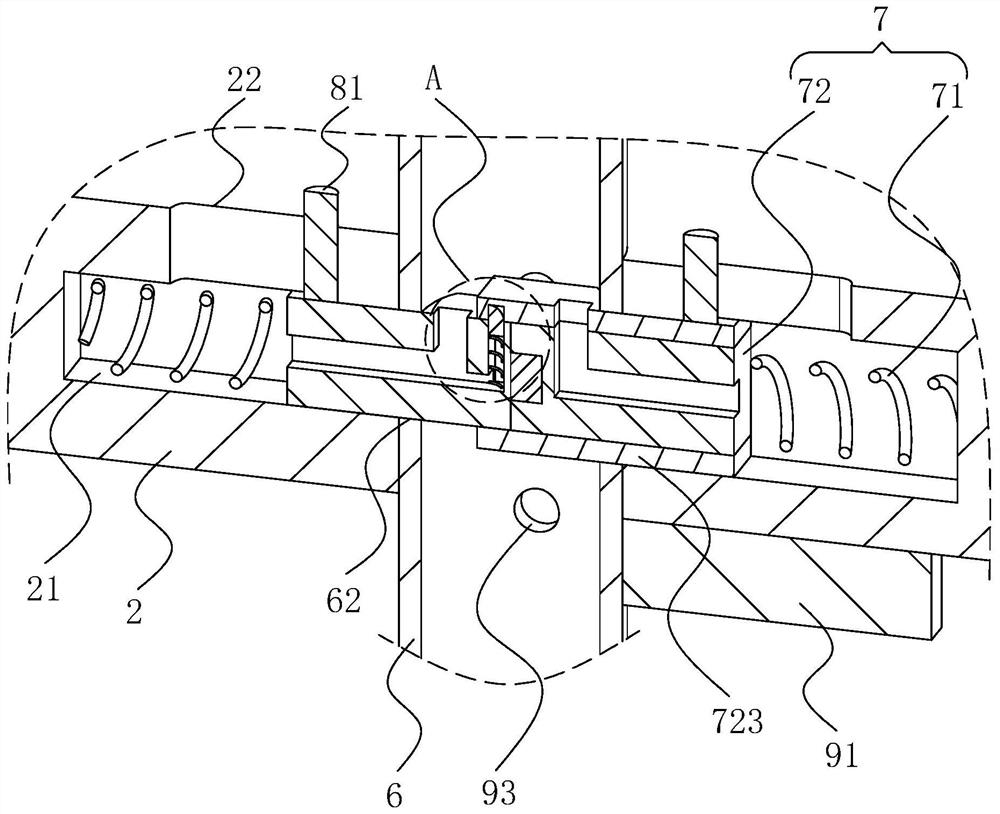

[0039] refer to figure 1 The inspection well lifting construction structure includes a subgrade surface 13 that is flush with the upper end surface of the old inspection well 1 and is located around the old inspection well 1. The subgrade surface 13 is set horizontally, and the upper end surface of the old inspection well 1 is fixedly connected with a new vertically installed inspection well. 11. The upper end of the new inspection well 11 is fixed with a well cover 12 to close it, and the subgrade surface 13 is fixed with a horizontal anti-settling board 2, and the upper surface of the anti-settling board 2 is fixed with the first cement-stabilized gravel base 3 , the upper surface of the first cement-stabilized gravel base 3 is fixedly laid with a horizontally arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com