Liquid flow passage box of dynamic magnetic filter

A magnetic filter and liquid flow channel technology, applied in the fields of filtration and separation, chemical instruments and methods, separation methods, etc., can solve the problems of easy sinking of ferromagnetic impurities, no new suspension, low water quality update frequency, etc., and achieve optimization. Use, improve the flow state, reduce the effect of bottom sinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings of the embodiments.

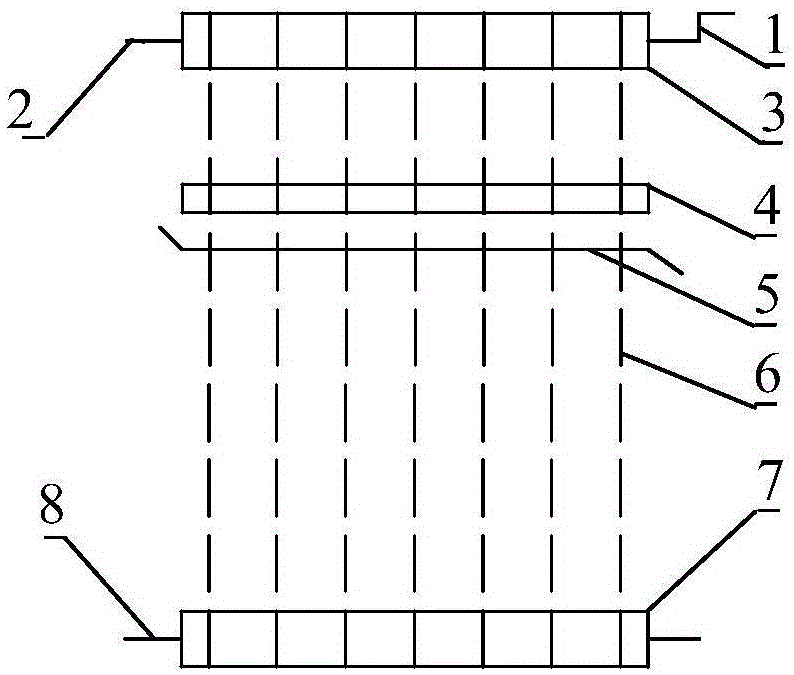

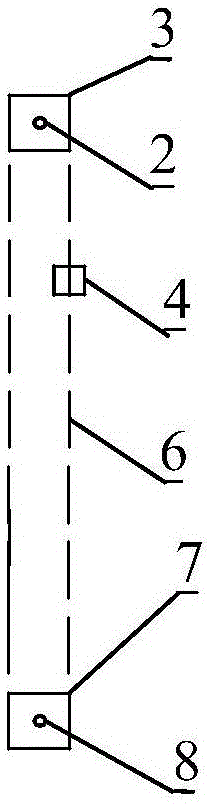

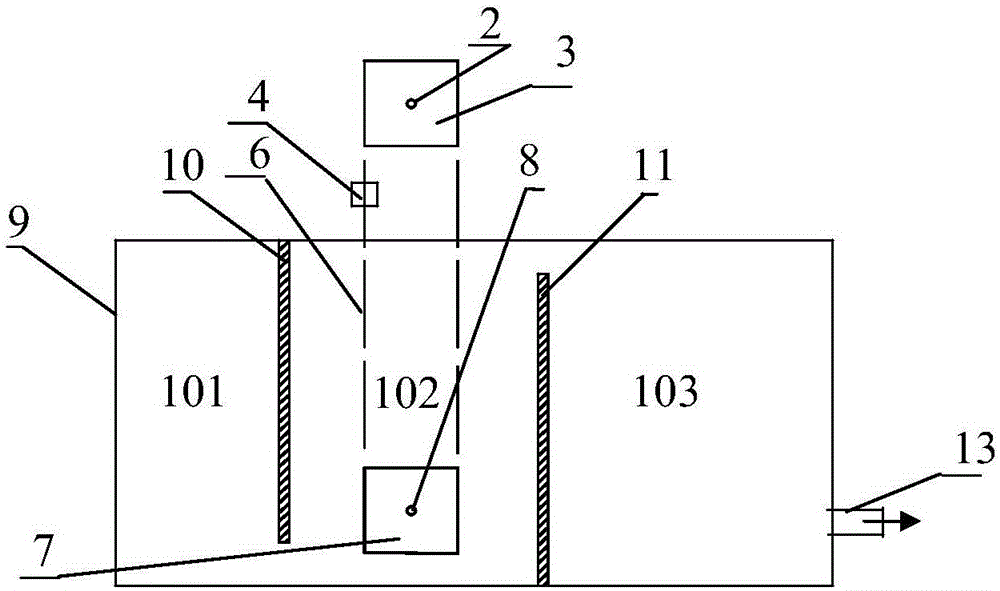

[0031] In the liquid channel box of the dynamic magnetic filter of the present invention, the structure of the dynamic magnetic filter adopts the structure shown in Figure 1, which consists of a driving mechanism 1, a driving shaft 2, a driving wheel 3, and a scraping device 4 , a chip removal groove 5, a multi-section magnetic bar 6, a driven runner 7 and a driven rotating shaft 8; the liquid flow channel box is a rectangular box 25, and the magnetic bar 6 is inserted in the rectangular box 25, The upper end of magnetic bar 6, driving mechanism 1, driving shaft 2, driving runner 3, scraping device 4 and chip removal groove 5 are positioned at above the upper edge of rectangular casing 25, and the top of rectangular casing 25 is open, and its front top is provided with The input pipeline 26 of the suspension i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com