Automatic meter modeling method based on machine vision

A machine vision and automatic modeling technology, applied in neural learning methods, instruments, calculations, etc., can solve the problems of poor scalability, labor-intensive automatic recognition technology of pointer tables, and high errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

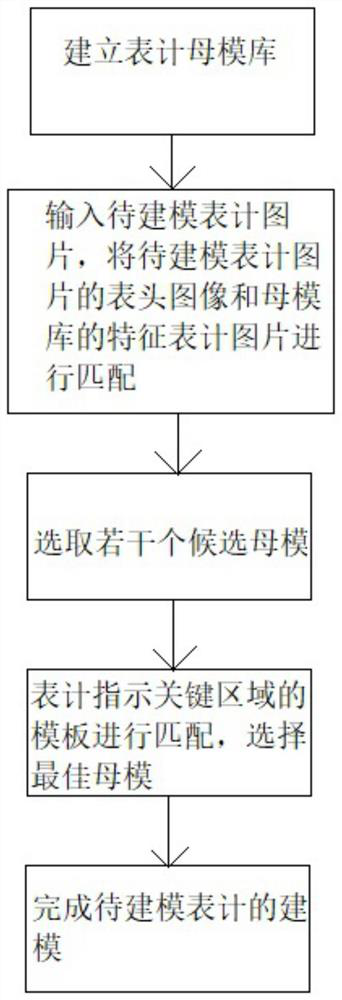

[0067] Embodiment 1: a kind of meter automatic modeling method based on machine vision, such as figure 1 shown, including the following steps:

[0068] Step 1. Establish a meter master model library, which includes characteristic meter pictures, establish a meter header detection network using faster-rcnn and perform training, and establish a reid classification network and perform training;

[0069] Step 2: Input the image of the meter to be modeled, find the header image of the meter image to be modeled according to the meter header detection network, and then use the reid classification network to combine the image of the meter header of the meter image to be modeled and the characteristics of the master mold library Meter pictures for matching;

[0070] Step 3, after the matching is completed, arrange the characteristic meter pictures of the master mold database in order according to the confidence degree from high to low, and select the characteristic meter pictures of t...

Embodiment 2

[0099] Embodiment 2, a meter automatic modeling method based on machine vision, its principle and implementation method are different from Embodiment 1 in that:

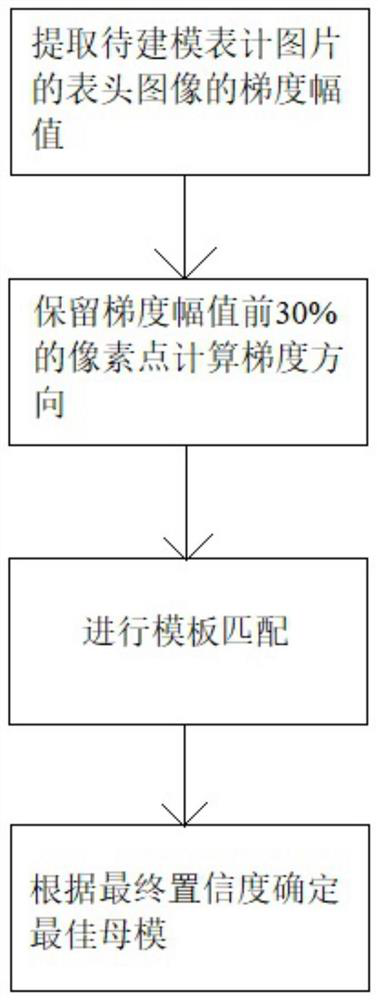

[0100] The meter is a screw oil level gauge. In step 4, the key area indicated by the meter is the screw area and the central circle area. The matching includes the following steps ( Figure 5 ):

[0101] Step 4-5, select the candidate master mold with the highest confidence, and judge whether the number of screw types of the meter image of the meter to be modeled is consistent with the number of screw types of the candidate master mold with the highest confidence, and if they are consistent, skip Go to step 4-7, if not consistent, go to step 4-6;

[0102] Step 4-6, remove the candidate master model with the highest confidence, repeat steps 4-4 in the remaining candidate master models, if there is no candidate master model, it is judged that the matching fails;

[0103] Steps 4-7, respectively calculate the angle b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com