Steel plate loading and unloading system of coating machine

A loading and unloading system and coating machine technology, which is applied in the direction of transportation and packaging, conveyor objects, load hanging components, etc., can solve the problems of low degree of automation and potential safety hazards, and achieve the effect of eliminating manual suspension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

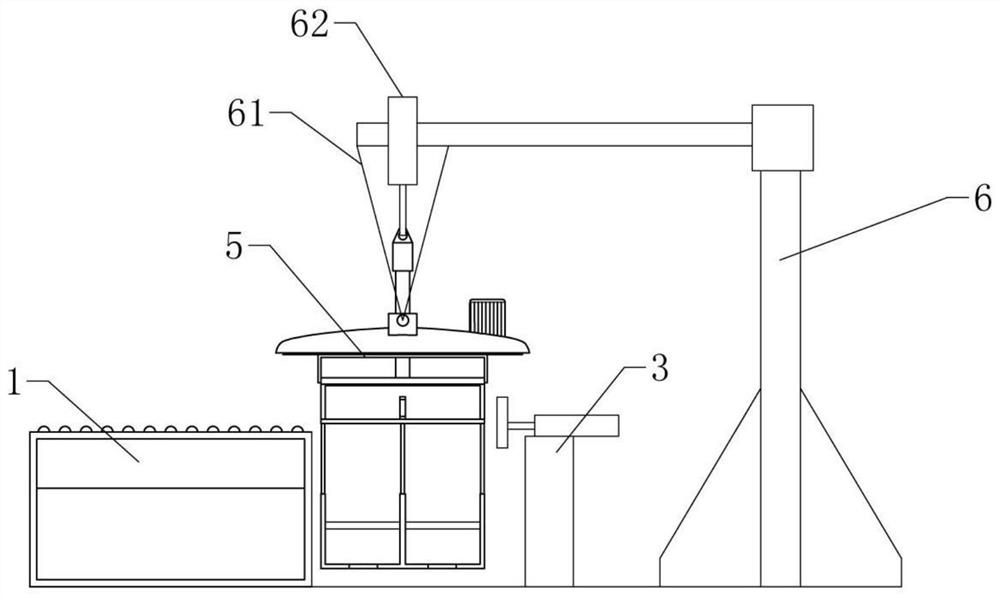

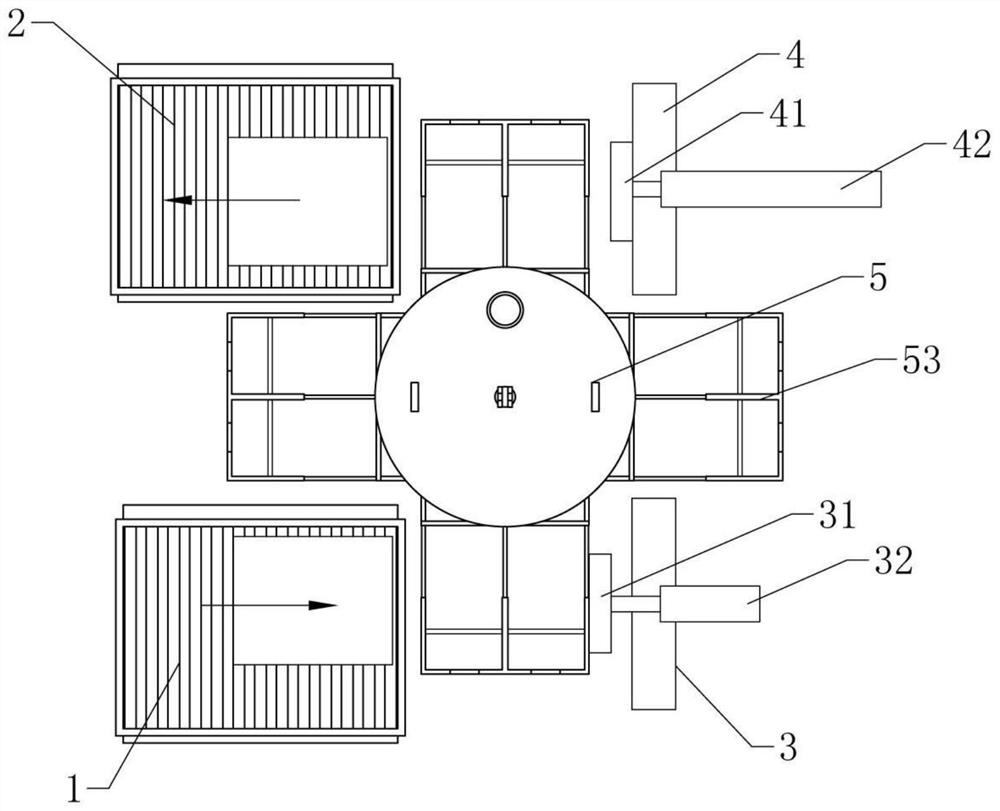

[0022] according to Figure 1 ~ Figure 4 As shown, a steel plate loading and unloading system of a coating machine includes a plate feeding conveying platform 1, a plate discharging conveying platform 2, a plate entering stopper 3, a plate pushing platform 4, a folding coating hanger 5 and a lifting device 6. Conveyor table 1, board entry stopper 3, board exit conveyance table 2 and board exit pusher 4 are arranged in two rows distributed on both sides of the folding coating hanger 2, between board feed conveyance table 1 and board feed stopper 3 And there is a space for turning over the coating hanger 2 between the plate delivery platform 2 and the plate pushing platform 4.

[0023] The hoisting device 6 includes a sling 61 and a control cylinder 62 , the board-in baffle 3 includes a baffle 31 and a baffle adjustment cylinder 32 , and the board-out pusher 4 includes a push plate 41 and a push plate cylinder 42 .

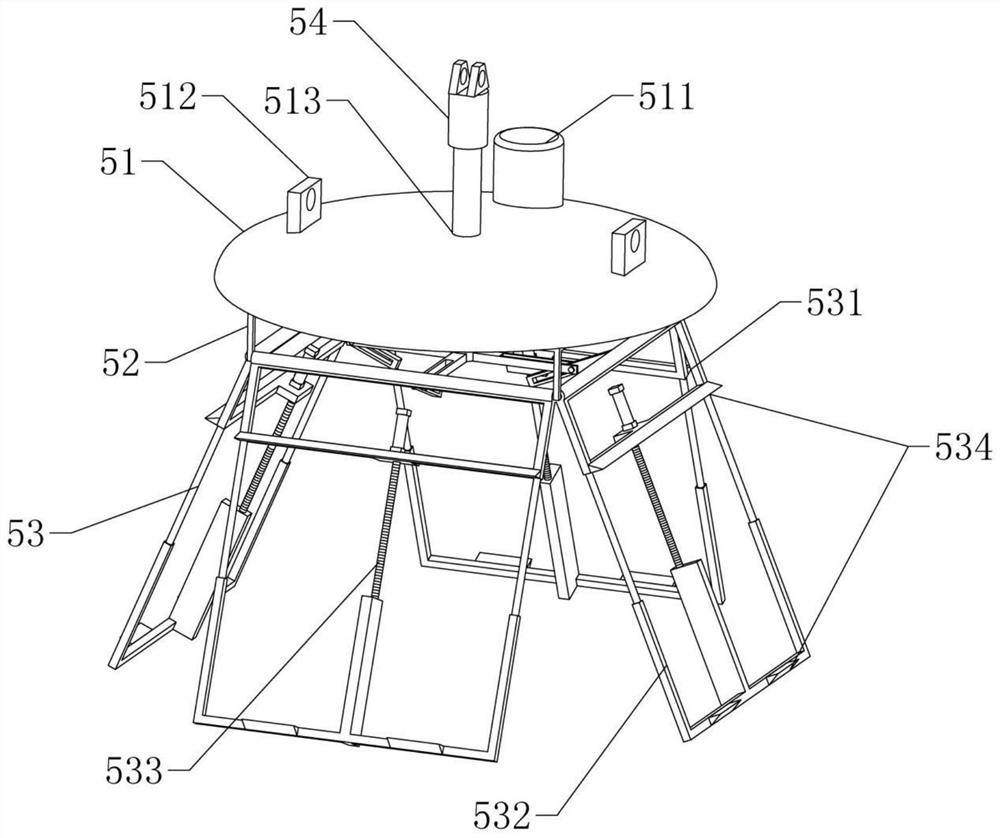

[0024] according to image 3 , Figure 4 As shown, the fold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com