Steel plate coating line capable of automatically feeding plates

A coating line and steel plate technology, which is applied in the field of steel plate processing, can solve the problems of hidden safety hazards and low degree of automation, and achieve the effect of improving processing efficiency and ensuring operation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

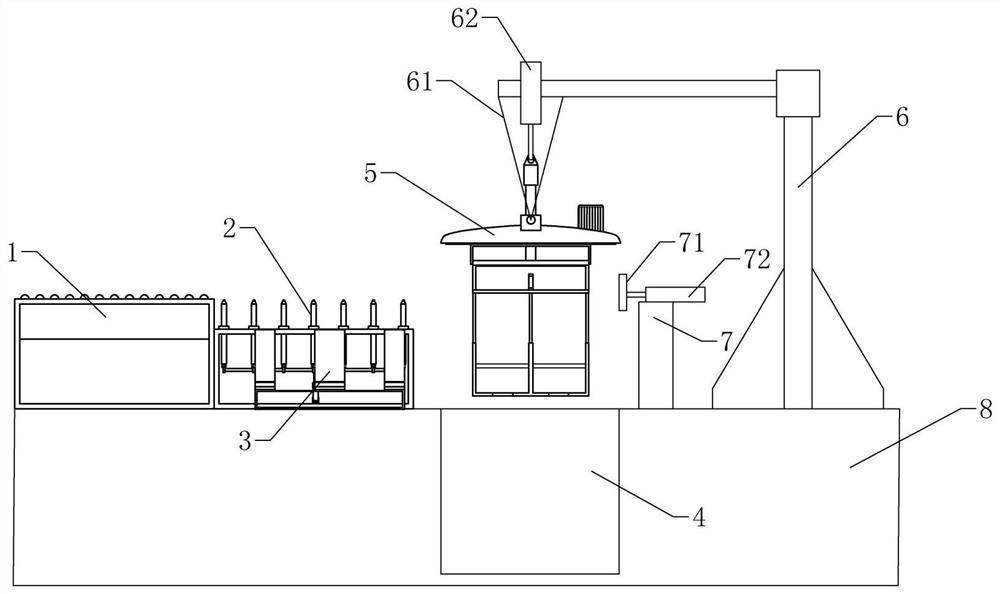

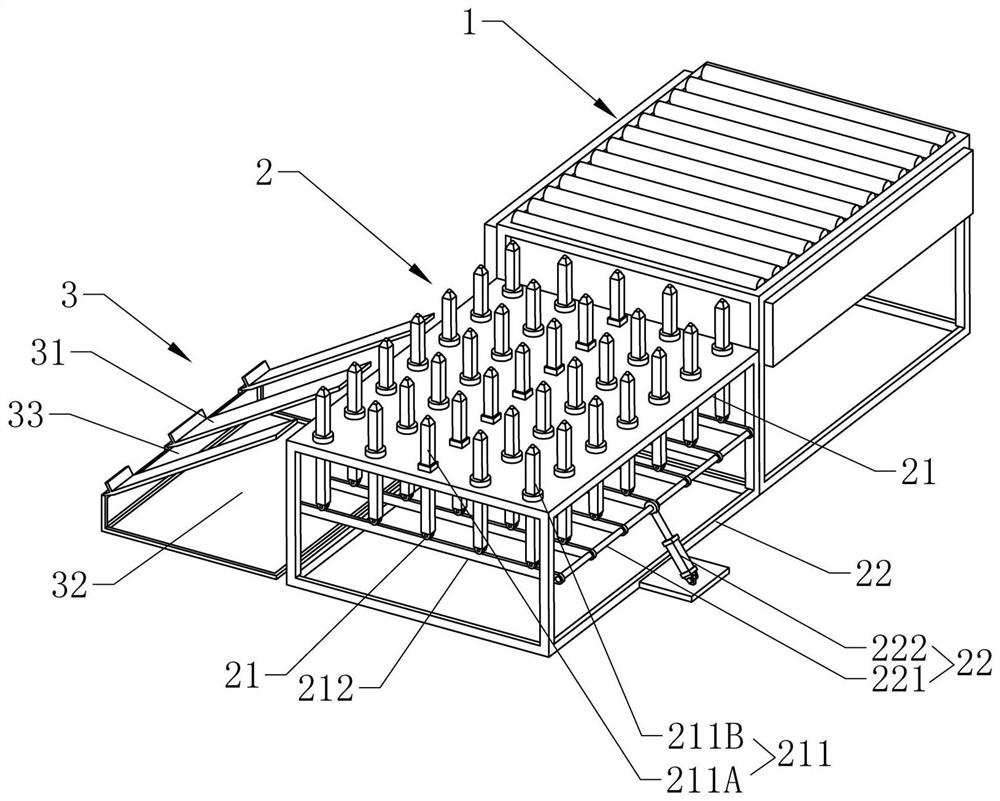

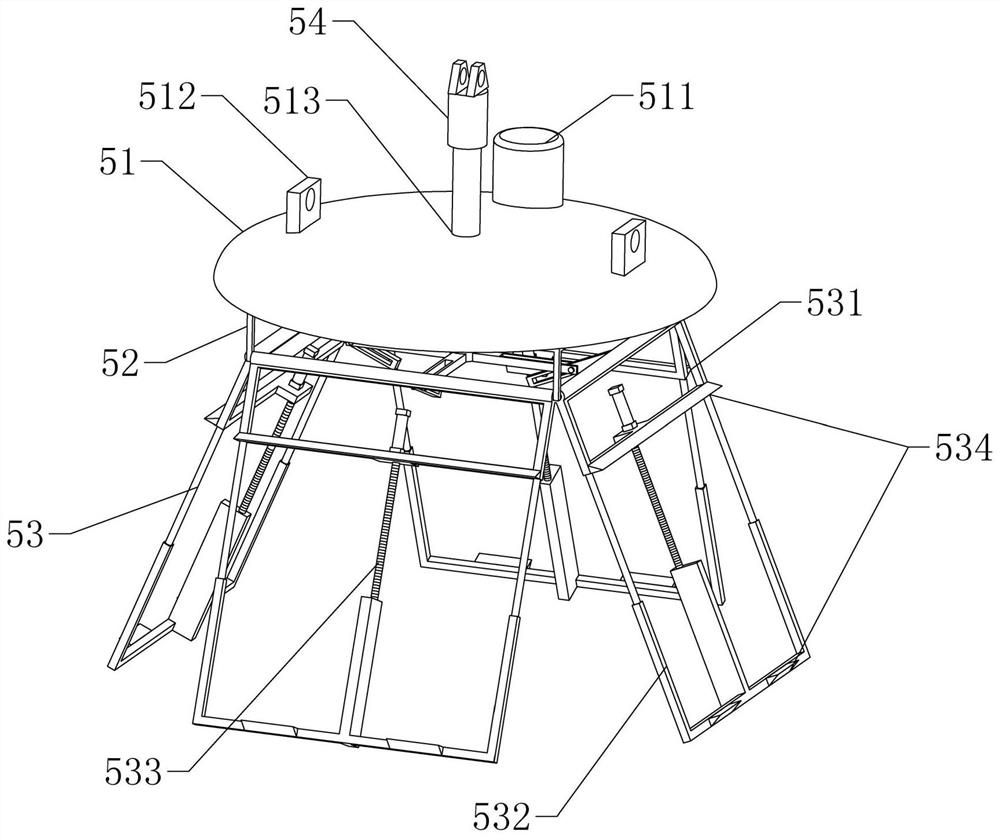

[0028] according to Figure 1 ~ Figure 2 As shown, a steel plate coating line for automatic plate feeding includes a conveying platform 1, a deflection platform 2, a plate feeding vehicle 3, a coating warehouse 4, a folding coating hanger 5, a lifting device 6 and a push plate mechanism 7, and the conveying platform 1 , the deflection table 2, the trolley 3, the hoisting device 6 and the push plate mechanism 7 are all fixed above the platform 8. The hoisting device 6 includes a sling 61 and a control cylinder 62 , and the pushing plate mechanism 7 includes a pushing plate 71 and a pushing plate cylinder 72 .

[0029] according to figure 2 As shown, the deflection table 2 is provided with several side-by-side transport deflection frames 21 and its supporting deflection control mechanism 22. The deflection table 2 includes a table top 21 and a bracket 22; the transport deflection frame 21 includes a transmission column 211 and a rotating link 212. The top of the column 211 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com