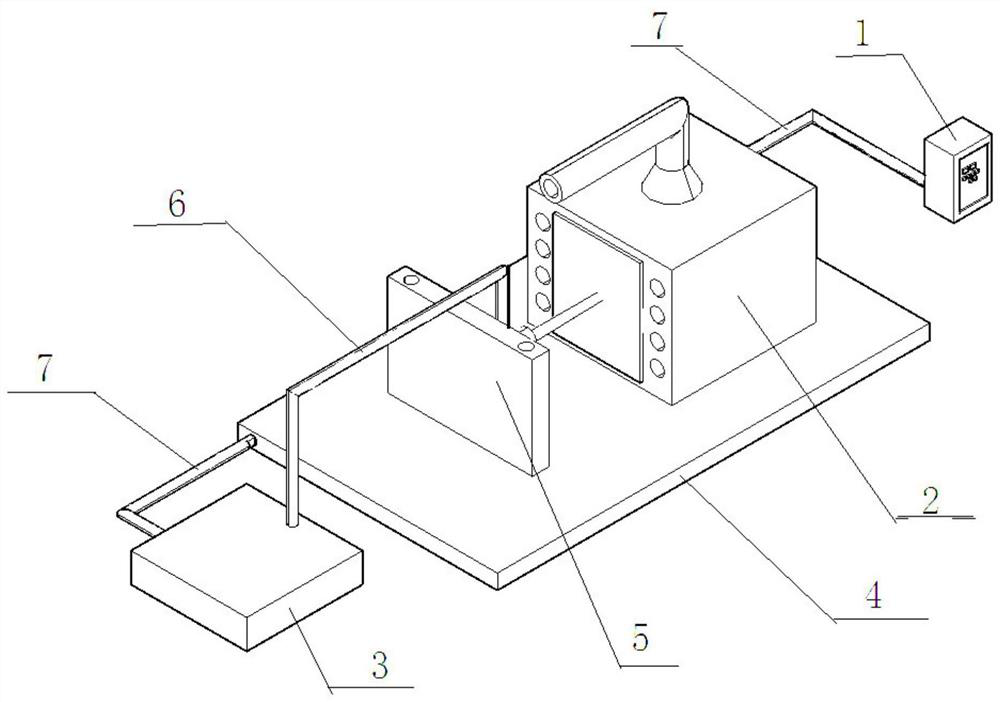

A small single-hole pressure swing coking device and a pressure swing coking method

A small, coke oven technology, used in coke ovens, energy input, special forms of dry distillation, etc., can solve problems such as inability to carry out pressure swing coking, and achieve the effect of increasing correlation and reliability, and accurate test data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

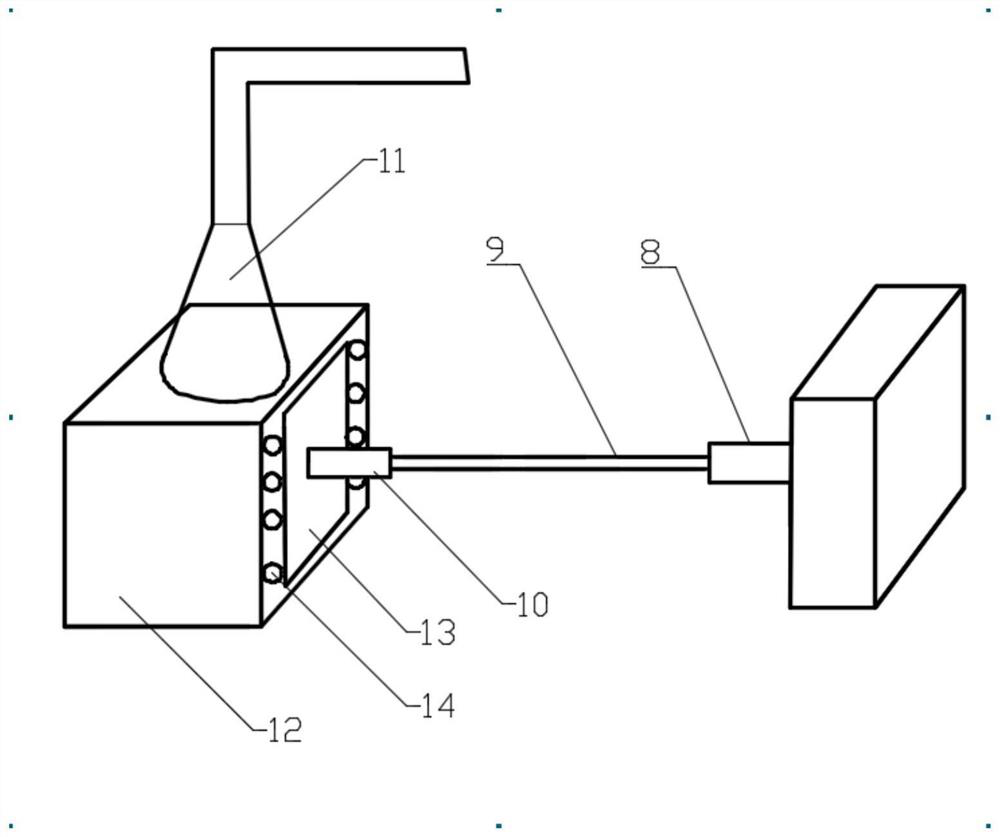

[0036] A method for pressure-variable coking using a small single-hole pressure-variable coking device, comprising the following methods:

[0037] 1) Start the control system, the coke oven starts to heat up, and the coke oven body reaches 1000°C within 2 hours;

[0038] 2) Weigh 2kg coal sample, put the coal sample into the coke oven body, close the furnace door, insert the connecting rod into the casing on the furnace door, and connect the other end of the connecting rod with the cylinder piston;

[0039] 3) Start the hydraulic adjustment system and adjust the hydraulic pressure in the cylinder to the set pressure: 0.2Mpa, which remains unchanged;

[0040] 4) Real-time detection of the coal sample temperature in the coke oven and the hydraulic pressure in the oil cylinder, when the coal sample temperature reaches 800℃, adjust the hydraulic pressure in the oil cylinder to the set pressure: 2.0Mpa;

[0041] 5) Real-time detection of the coal sample temperature in the coke ove...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap