Sewing machine capable of automatically feeding cloth

A sewing machine and cloth feeding technology, which is applied in the field of sewing, can solve problems such as uneven force, uneven sewing between cloth, and gathered wrinkles, so as to achieve the effect of improving the appearance, ensuring flatness, and flatness under pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

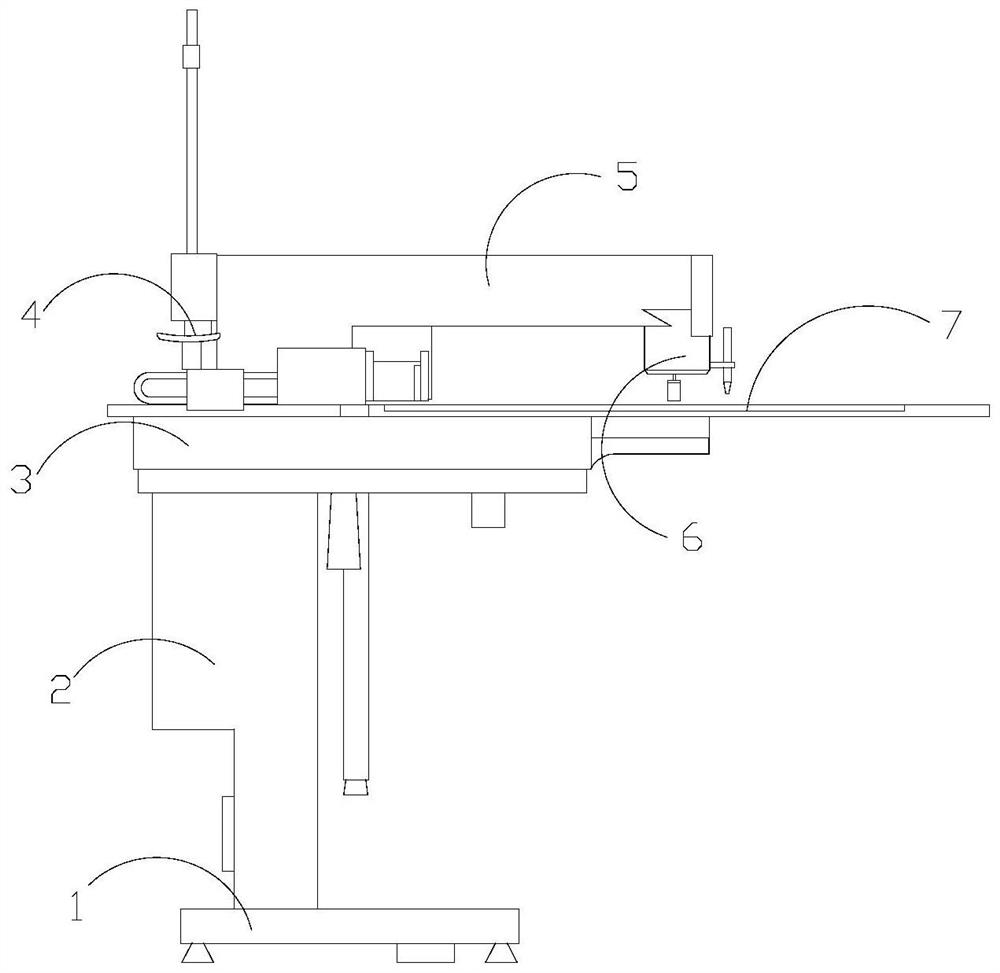

[0028] Example 1: Please refer to Figure 1-Figure 5 , the specific embodiment of the present invention is as follows:

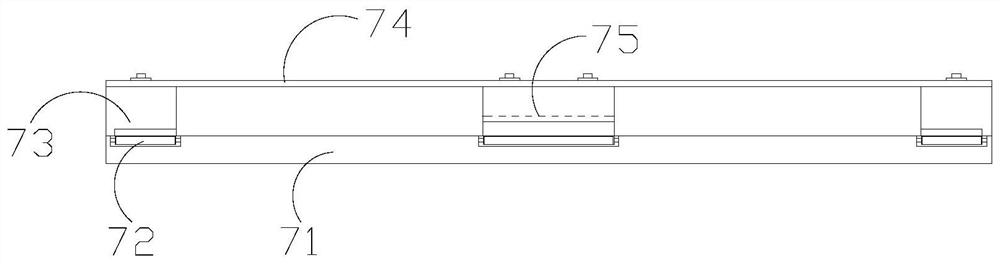

[0029] Its structure includes a base 1, a frame 2, a workbench 3, a placing frame 4, a beam 5, a machine head 6, and a cloth feeding structure 7. The frame 2 is vertically installed on the upper end of the base 1 and is mechanically connected. The workbench 3 is horizontally installed on the upper end of the frame 2 and welded to each other, the lower end of the placement rack 4 is embedded and installed on the inner side of the workbench 3 and is connected by screw threads, and the beam 5 is horizontally installed on the upper end of the workbench 3 and is mechanically connected, so The machine head 6 is embedded and installed at the inner front end of the beam 5 and connected to each other. The cloth feeding structure 7 is horizontally installed on the upper end of the worktable 3 and is located below the machine head 6; the cloth feeding structure 7 inclu...

Embodiment 2

[0035] Example 2: Please refer to image 3 , Figure 6-Figure 8 , the specific embodiment of the present invention is as follows:

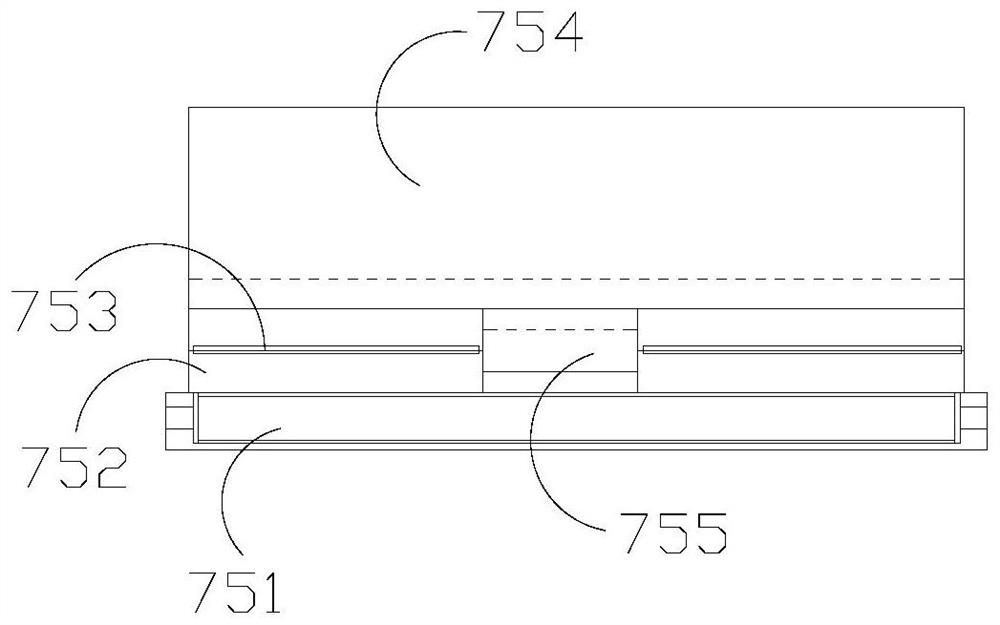

[0036] The conveying structure 75 includes a driving roller 751, a notch 752, a driven belt 753, a body 754, and a pressing structure 755. The notch 752 is provided on the upper end of the driving roller 751 and is an integrated structure, and the driven belt 753 is embedded Installed on the inside of the body 754 and connected movably, the pressing structure 755 is embedded in the bottom of the inside of the body 754 and installed above the driving roller 751 , and the driven belt 753 is arranged on both sides of the pressing structure 755 .

[0037] see Image 6 , the pressing structure 755 includes an outer shaft 55a, a drive plate 55b, a push frame 55c, a conveyor belt 55d, and a pressing port 55e. The drive discs 55b are connected in an active manner. The conveyor belt 55d is engaged with the outside of the drive disc 55b and abuts against...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com