A prefabricated concrete self-resetting beam-column composite node connection structure and assembly method

A technology for combining nodes and connecting structures, which is applied to building components, building structures, protective buildings/shelters, etc., can solve problems such as brittle damage at the grouting place, difficulty in replacement and repair, and complex grouting methods, so as to enhance the overall Reliability, convenient and quick replacement, and the effect of reducing residual deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

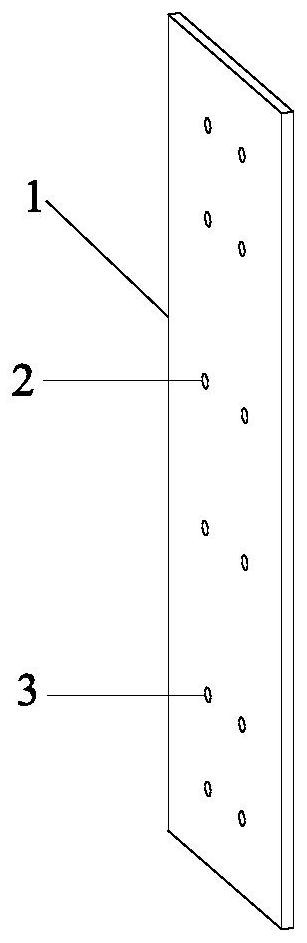

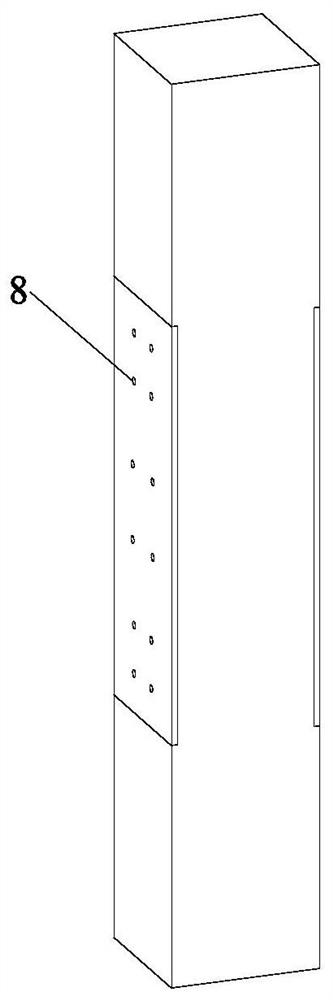

[0054] The embedded steel plate in the column includes a rectangular steel plate I1, a number of prestressed rib holes I2 and a number of bolt holes I3.

[0056] The embedded steel plate in the beam includes a rectangular steel plate II9 and a number of prestressed rib holes II10, and the rectangular steel plate II9 is on the

[0058] The grooved steel plate includes a grooved steel plate 18, a number of bolt holes II19, a notch 20 and an anchor bolt hole I21.

[0059] The rectangular anchor includes an anchor steel piece 28 and several anchor bolt holes II 29, and the anchor steel piece 28 is provided with

[0065] The embedded steel plate in the column (Fig. 1) consists of a rectangular steel plate I1, a prestressed rib hole I2 and a bolt hole I3.

[0066] The two sides of the plate wall of the rectangular steel plate I1 are provided with prestressed rib holes I2 and bolt holes I3 by means of double-sided through drilling,

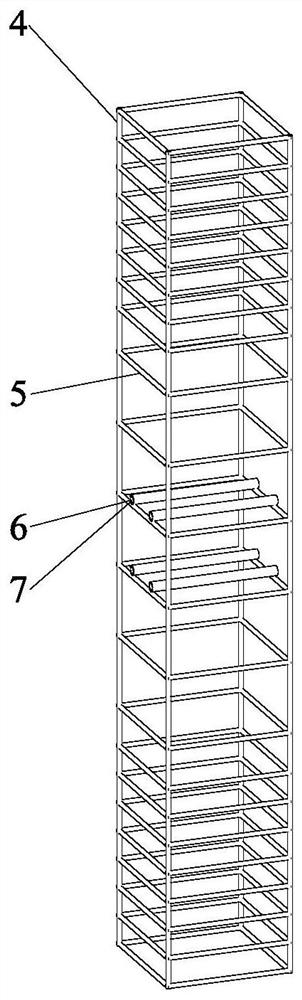

[0068] The reinforcement in the column is made up of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com