Telescopic supporting structure

A technology of telescopic support and telescopic mechanism, which is applied in the direction of building construction, residential construction, casters, etc., can solve the problems of heavy workload, high labor cost, and long time consumption, and achieve long service life, stable structure, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

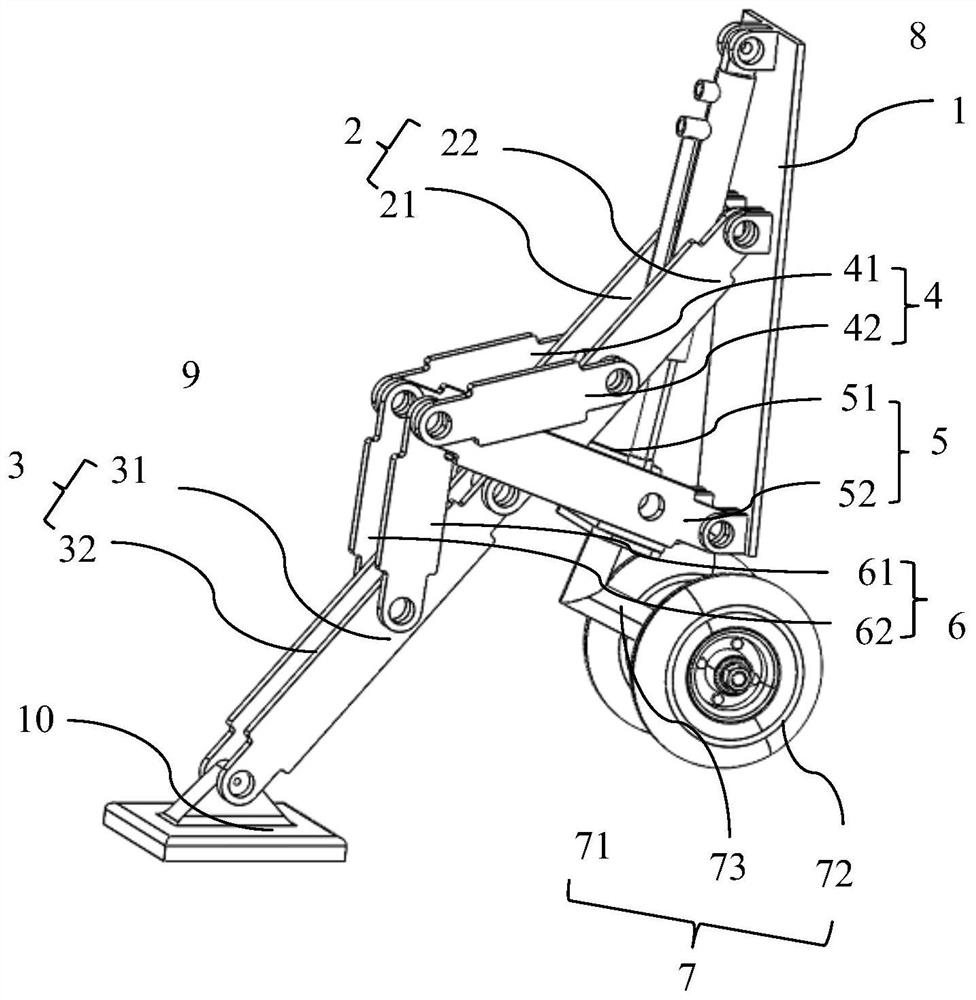

[0038] Such as figure 1 As shown, a telescopic support structure in a preferred embodiment of the present invention includes a base plate 1 , a support rod, a reinforcing rod and a hydraulic column 8 .

[0039] The support rods include a first left support rod 21 and a first right support rod 22 arranged in parallel, a second left support rod 31 and a second right support rod 32 arranged in parallel, and the first left support rod 21 and the second right support rod 32 which are hinged to each other. The two left support rods 31 are arranged on the left side of the hydraulic column 8, and the mutually hinged first right support rod 22 and the second right support rod 32 are arranged on the right side of the hydraulic column 8;

[0040] The reinforcing bar comprises a first left reinforcing bar 41 and a first right reinforcing bar 42 arranged in parallel, a second left reinforcing bar 51 and a second right reinforcing bar 52 arranged in parallel, and a third left reinforcing ba...

Embodiment 2

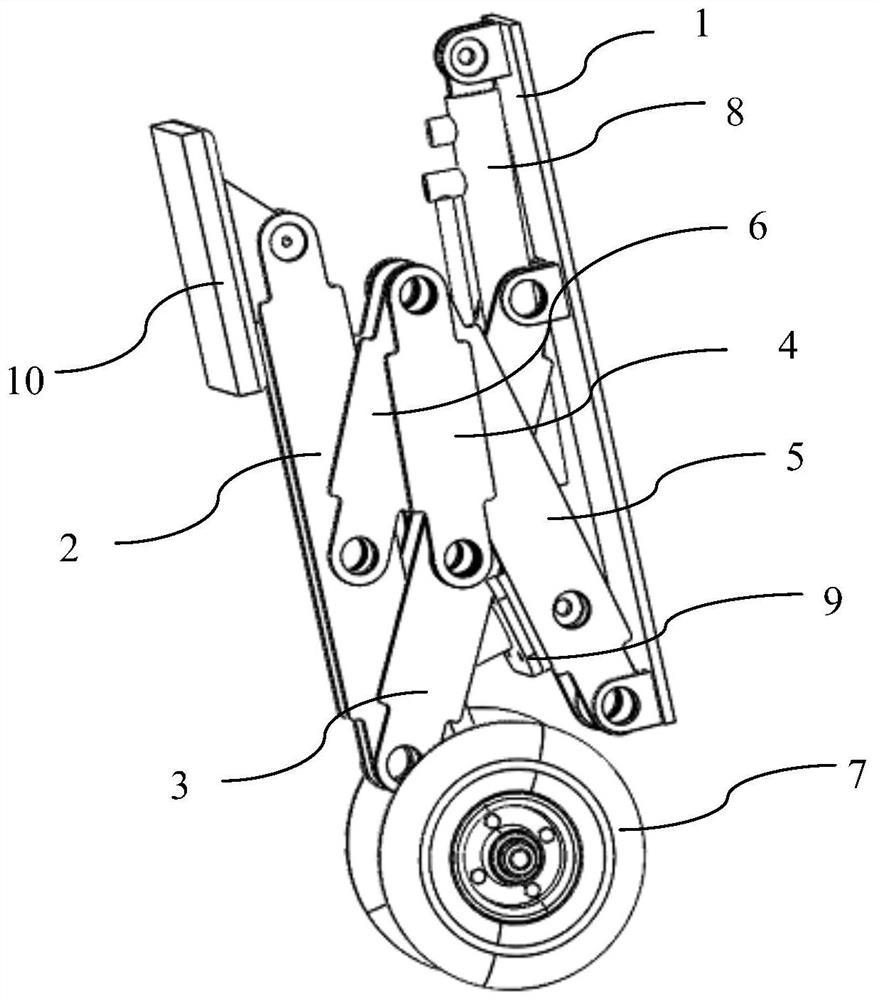

[0048] A telescopic supporting structure, comprising a base plate 1, a supporting rod, a reinforcing rod and a telescopic mechanism. The support rod includes a first support rod 2 and a second support rod 3, one end of the first support rod 2 is hinged on the base plate, and the other end of the first support rod 2 is hinged with the second support rod 3; A reinforcement rod 4, a second reinforcement rod 5 and a third reinforcement rod 6, the other end of the first reinforcement rod 4 is hinged to the first support rod 2, the other end of the second reinforcement rod 5 is hinged to the base plate 1, and the third reinforcement rod 6 is in addition One end is hinged to the second support rod 3; one end of the telescopic mechanism is connected to the base plate, and the other end is connected to the second support rod 3.

[0049] The lower part of the second reinforcing rod 5 is provided with a limiting plate 9, the lower end of the hydraulic column 8 is connected to the limitin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com