Inserting type vibration device

A vibrating device and plug-in technology, applied in construction, building structure, construction material processing and other directions, can solve the problems of high labor cost, difficult application, high labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

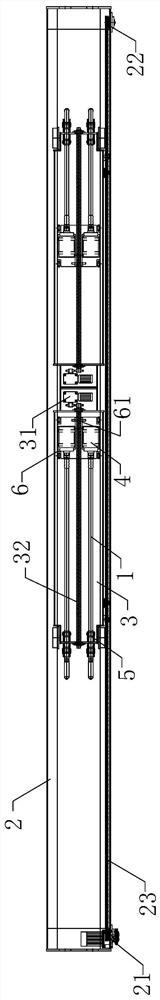

[0026] Figure 1 to Figure 4 An embodiment of the plug-in vibrating device of the present invention is shown. The plug-in vibrating device of this embodiment includes a vibrating rod 1, a track frame 2 and a mobile trolley 3 arranged on the track frame 2, and the mobile trolley 3 There is a vibrating driver 4, a vibrating rod guide 5, and a vibrating trolley 6 for driving the vibrating driving part 4 to reciprocate. The vibrating rod 1 is connected with the vibrating driving part 4, and the vibrating driving part 4 Set on the vibrating trolley 6. Wherein, the vibrator bar guide 5 can be, for example, a pair of guide wheels, and the vibrator 1 is sandwiched between the pair of guide wheels, and the vibrator driver 4 can be, for example, a common vibrator motor etc.; Horizontally arranged, correspondingly, the mobile trolley 3 and the vibrating trolley 6 both move laterally. Wherein, the vibrator guide 5 can be a pair of guide wheels, and the vibrator 1 is sandwiched between t...

Embodiment 2

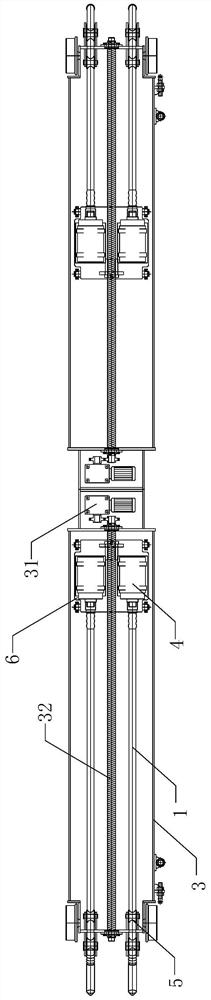

[0034] Figure 5 to Figure 6 Another embodiment of the plug-in vibrating device of the present invention is shown. The plug-in vibrating device of this embodiment is basically the same as the first embodiment, the difference is that in this embodiment, two One mobile trolley 3, two mobile trolleys 3 are arranged in parallel, and the vibrating rods 1 on the two mobile trolleys 3 face opposite. The front and rear sides of the track frame 2 can be vibrated simultaneously, which is conducive to improving construction efficiency and is suitable for concrete construction surfaces with large longitudinal dimensions.

[0035]Further, in this embodiment, the track frame 2 is provided with a mobile trolley drive assembly, and the mobile trolley drive assembly includes a driving sprocket 21, a driven sprocket 22, and a driving sprocket 21 and a driven sprocket 22. The chain 23 of two mobile dollies links to each other, and one of them mobile dolly 3 links to each other with chain 23. S...

Embodiment 3

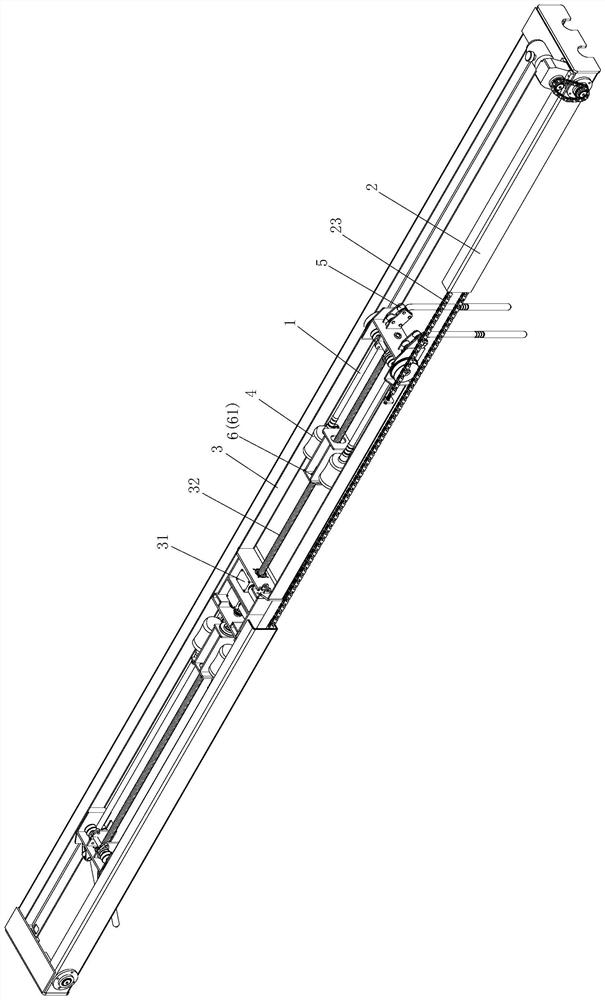

[0037] Figure 7 Another embodiment of the plug-in vibrating device of the present invention is shown. The plug-in vibrating device of this embodiment is basically the same as that of Embodiment 1, the difference is that there are two vibrating rods 1, two vibrating rods The tampering rods 1 are arranged in parallel, and two adjacent vibrating rods 1 are facing oppositely. Correspondingly, two vibrating dollys 6 are arranged on the mobile trolley 3, and each vibrating dolly 6 is provided with a vibrating driving member 4, each The vibrating driving member 4 is connected to each vibrating rod 1 in a one-to-one correspondence. Of course, in other embodiments, the number of vibrating rods 1 can be further increased. In this embodiment, only one mobile trolley 3 is provided to realize simultaneous vibration at the left and right ends of the track frame 2 . Each vibrating trolley 6 can carry its own driving device to realize lateral movement, and also can adopt the sprocket drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com