VMD equipment fault diagnosis method and system

A diagnostic method and equipment failure technology, applied in complex mathematical operations, measuring devices, instruments, etc., can solve problems such as difficulty in determining the order of polynomial trend fitting, damage to the fractal structure of the original signal, manual determination of the analysis scale, etc., to avoid negative Effects of frequency phenomena, high accuracy, high accuracy and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

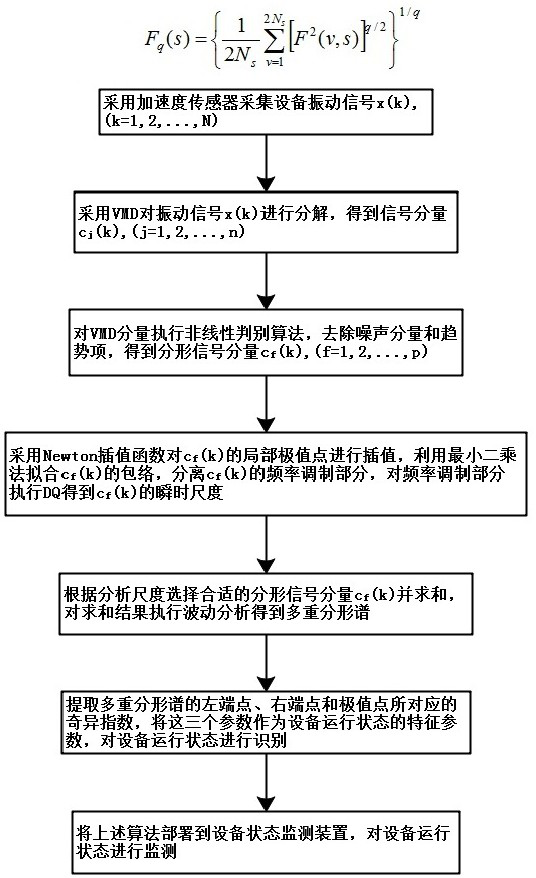

[0101] Examples such as figure 1 , figure 2 Shown, a kind of VMD equipment fault diagnosis method is characterized in that: comprise the following steps:

[0102] Step 1: Use the acceleration sensor to measure the equipment vibration signal x(k) at the sampling frequency fs, k=1, 2, ..., N, N is the length of the sampling signal;

[0103] Step 2: Use the Variational Mode Decomposition (VMD) algorithm to decompose the signal x(k) into the sum of n components and a trend item, namely , where c i (k) represents the i-th component obtained by the VMD algorithm, r n (k) represents the trend item obtained by the VMD algorithm, in this example, n=10;

[0104] The VMD algorithm is known, see literature

[0105] Konstantin Dragomiretskiy, Dominique Zosso. Variational Mode Decomposition, IEEE TRANSACTIONS ON SIGNAL PROCESSING, 2014, 62(3): 531-544;

[0106] Step 3: Use nonlinear discriminant algorithm to exclude noise components and trend items from the VMD decomposition results...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com