A kind of processing device of meltblown cloth

A processing device and a technology of melt-blown cloth, which is applied in the direction of non-woven fabrics, mechanical cleaning, textiles and papermaking, etc., can solve the problems of melt-blown cloth pulling distortion, poor quality, and difficulty in achieving multiple absorption, etc., and achieve improved Suction efficiency and the effect of improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

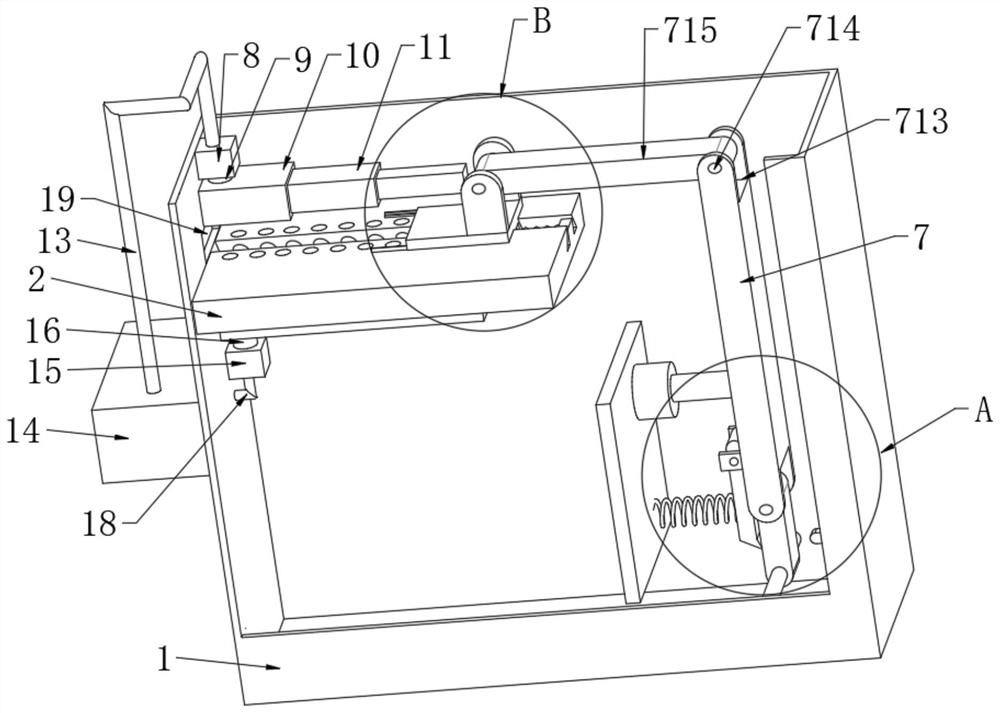

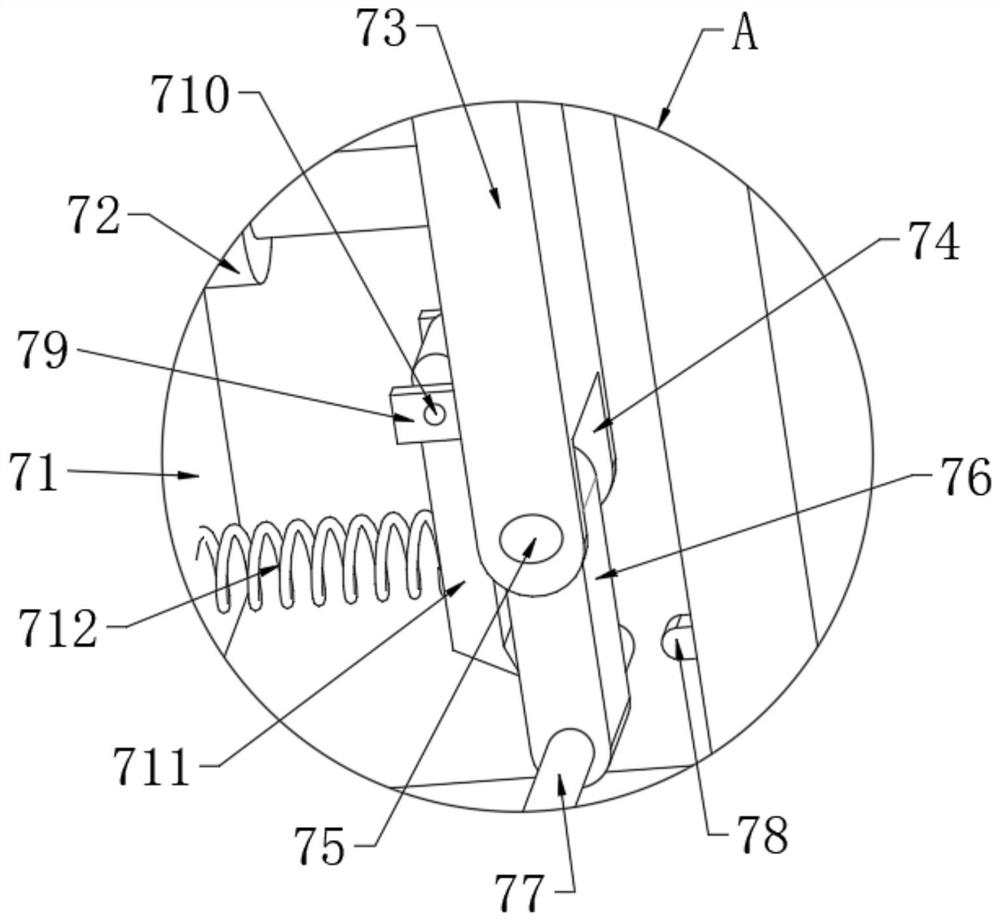

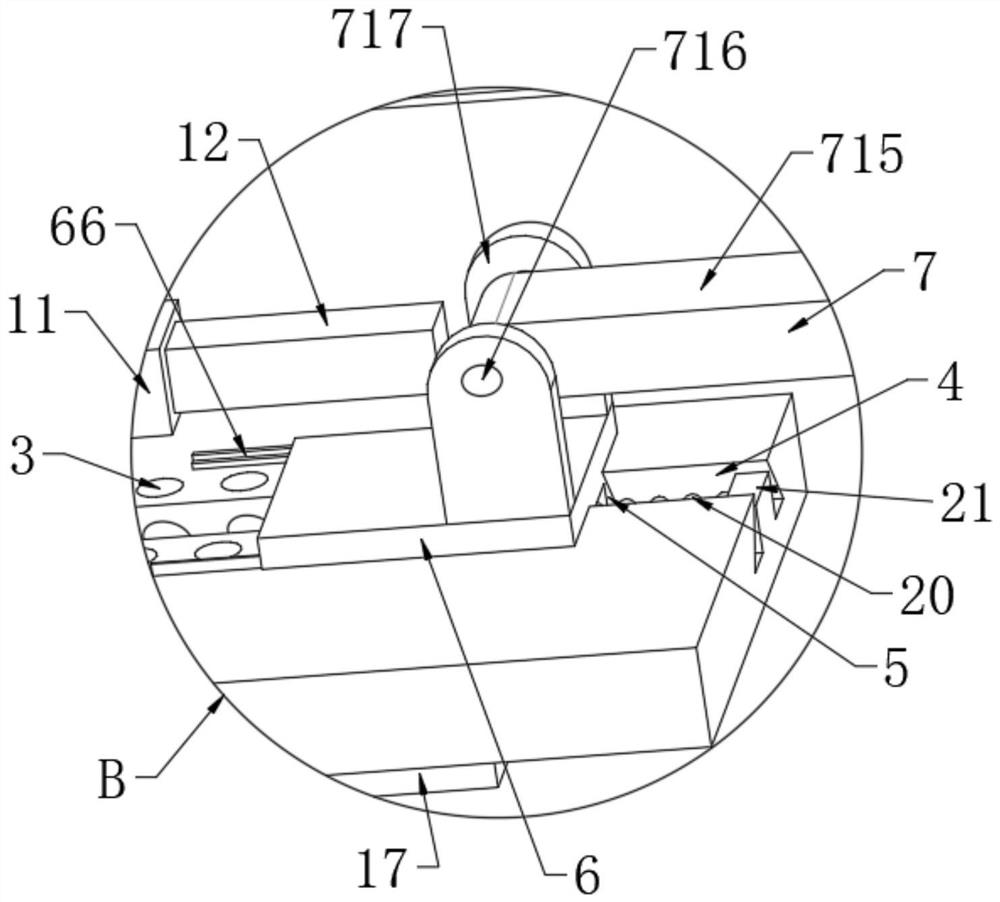

[0034] see Figure 1-6 , a processing device for melt-blown cloth, which is composed of a dust cover 1 , a pressing component 6 , a conveying component 7 , a first suction fan 8 and a second suction fan 15 .

[0035]Among them, the dust cover 1 can prevent dust from entering the pressing component 6, the conveying component 7 and other components, the inner wall of the dust cover 1 is welded with a first support plate 2, and the upper surface of the first support plate 2 is provided with a first sliding Slot 4, a first sliding block 5 is slidably connected to the inner wall of the first sliding groove 4. Through the mutual cooperation between the first sliding groove 4 and the first sliding block 5, the first sliding block 5 can be made to slide along the first sliding block 5. Orbital motion of slot 4.

[0036] Among them, because the texture of the melt-blown cloth is relatively light and thin, the melt-blown cloth will be adsorbed and attached to the suction inlet of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com