Needle cover for medical injection device

A technology for an injection device and a needle shield, which is applied in the field of needle shields and can solve problems such as the inability to remove the needle shield and the treatment of the injection device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

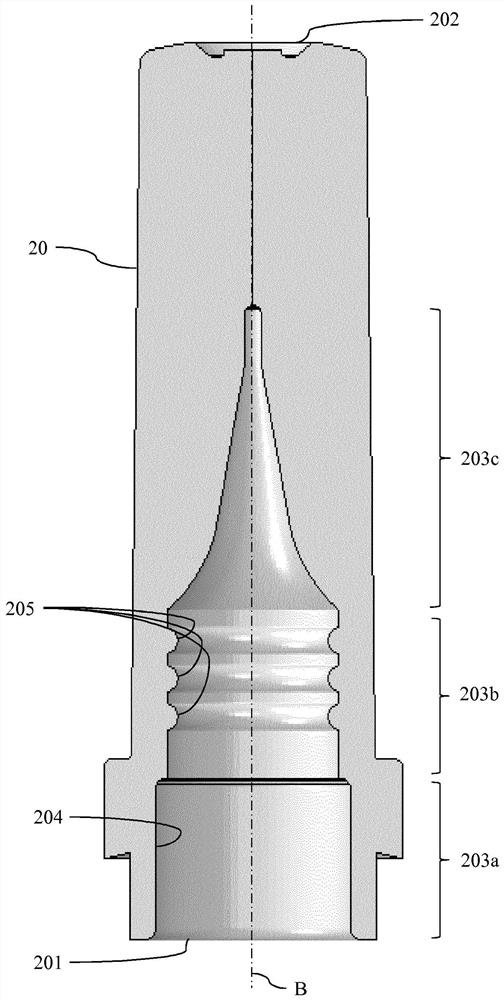

[0094] Three different designs of inner needle shield 20 (designated M) were molded from thermoplastic elastomer. exist Figure 4 These inner needle shields are shown in . The characteristics of these needle shields are described below and in Table 1.

[0095]

[0096] Table 1: Molded Needle Shields

[0097] "Radius" (R) refers to the radius (width) of each rib; "Height" (H) refers to the height of each rib; "Gap" (G) refers to the distance between two adjacent ribs; And "D" refers to the inner diameter of the inner needle shield at the inner sealing portion. For ribbed designs, when the inner needle shield is not inserted over the tip of the syringe, the diameter is measured at the top of the rib, as Figure 4 shown in . For all designs M1 , M2, M3 the needle shield was made of thermoplastic elastomer (TPE) and the injection device was a glass syringe.

[0098] will also refer to Figures 5A to 5C describe Figure 4 Designs M1, M2, M3 shown in, Figures 5A to 5C...

example 2

[0120] Example 2: Development of different designs of the sealing surface of the needle shield

[0121] To investigate the effect of the dimensions of the ribs and their number on the pull-out force, a finite element analysis was performed. The properties of thermoplastic elastomer materials (similar to those molded in Example 1) were used for this finite element analysis. Simulate needle shield removal and calculate pull-out force.

[0122] A simulated design of the sealing portion of the needle shield is described in Table 3 below.

[0123]

[0124]

[0125] Table 3: Alternative designs of the sealing portion of the needle shield

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com