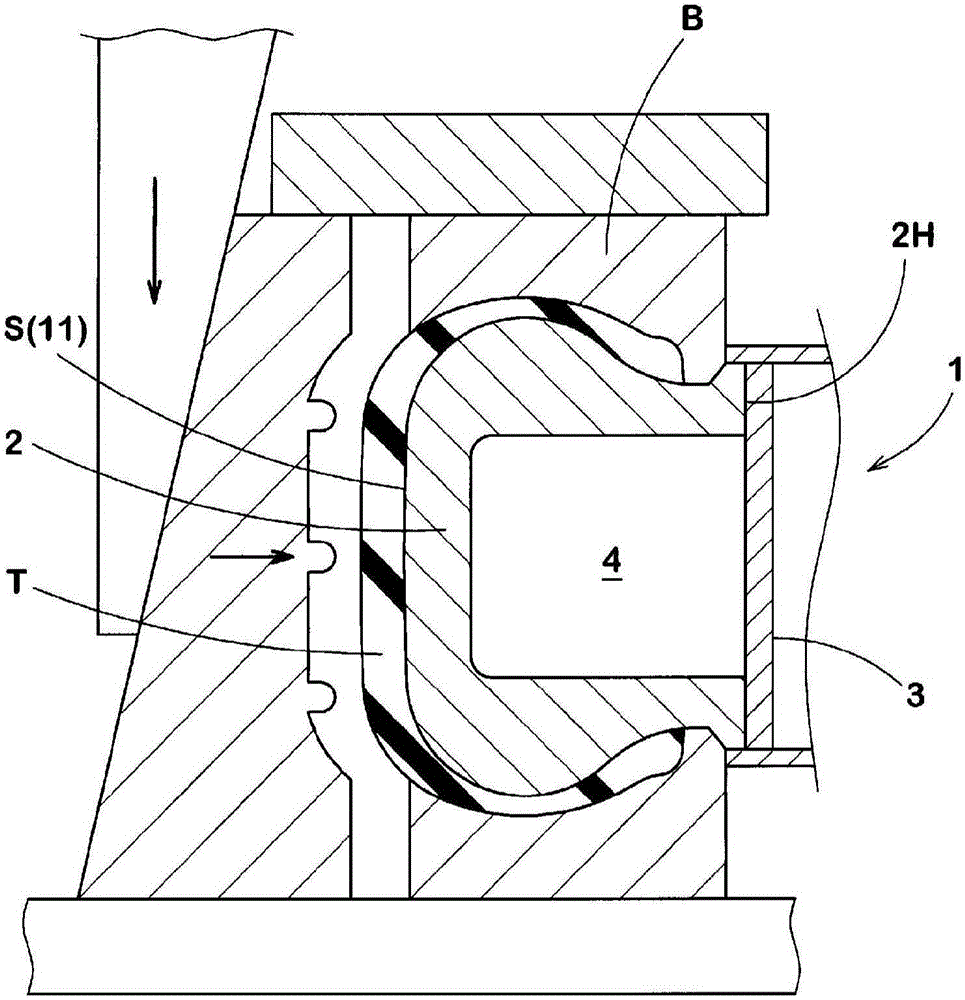

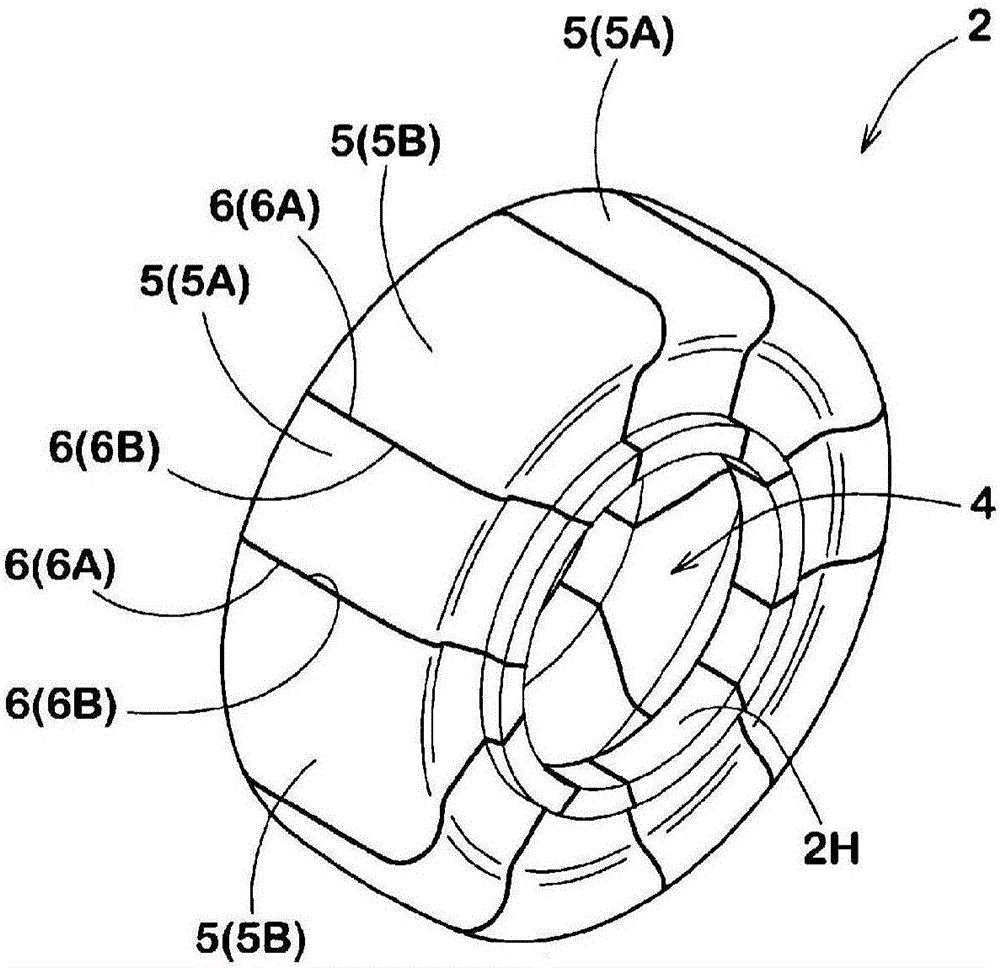

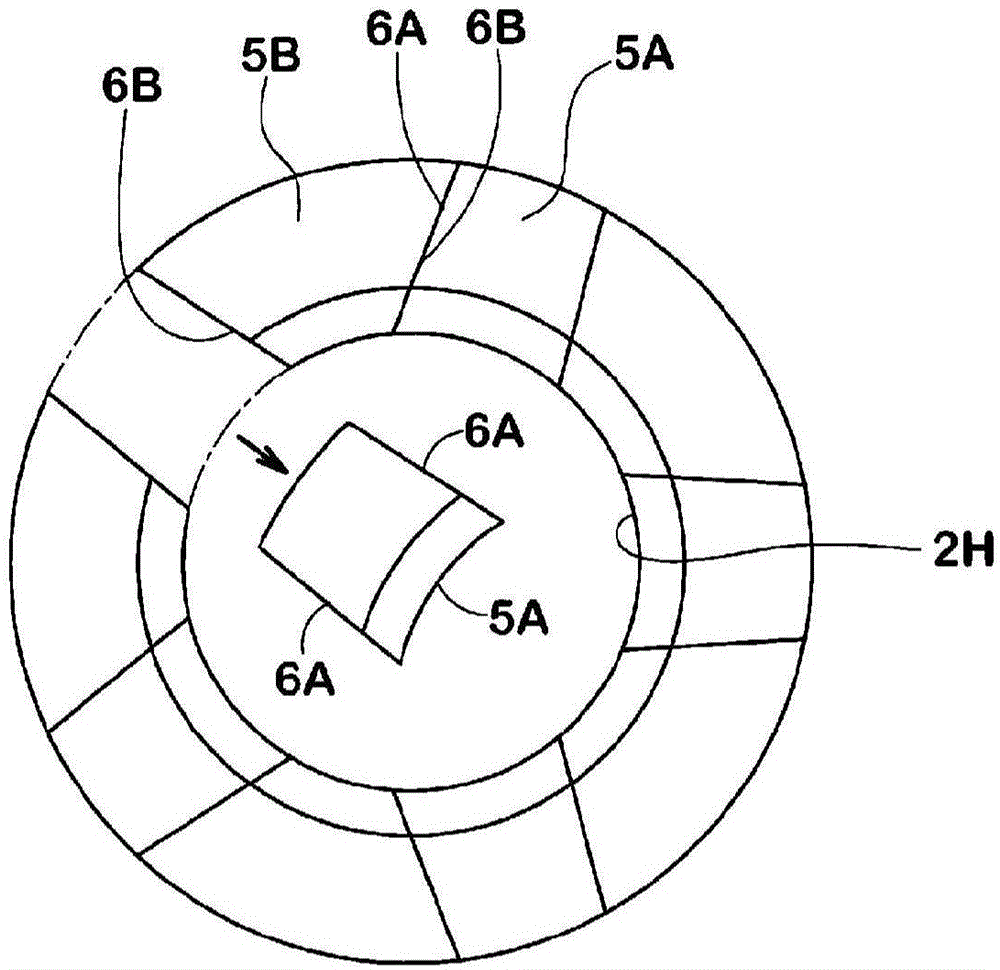

Rigid core for tire forming, and tire manufacturing method using same

A rigid core and tire forming technology, applied in tires, applications, household appliances, etc., can solve the problems of reduced production efficiency, longer time for disassembling and removing the main body of the core, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0048] In order to confirm the effect of the present invention, a pneumatic tire (245 / 40R18 ). In addition, the moldability of the green tire when forming a green tire, the removability of the core segment from the vulcanized tire, and the durability of the coating layer were examined and evaluated.

[0049] In Table 2, the rubber release properties and hardness of the coating layer described in Table 1 are represented by indices. Rubber release properties are based on the above Figure 6 The peeling detection was evaluated on a 5-point scale by the operator's senses. When the numerical value is large, the release property is excellent. In addition, regarding the hardness of the coating layer, a value measured in accordance with the "micro Vickers hardness test" described in the "Vickers hardness test-test method" of JIS Z 2244 was indexed.

[0050] (1) Green tire formability:

[0051] On the tire molding surface S of the core main body, an unvulcanized strip-shaped rubbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com