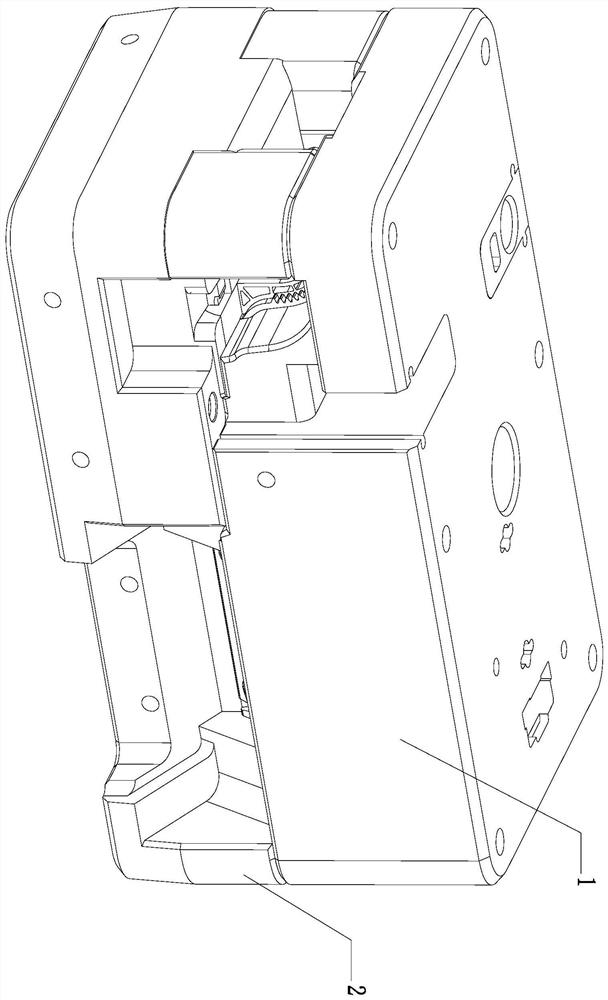

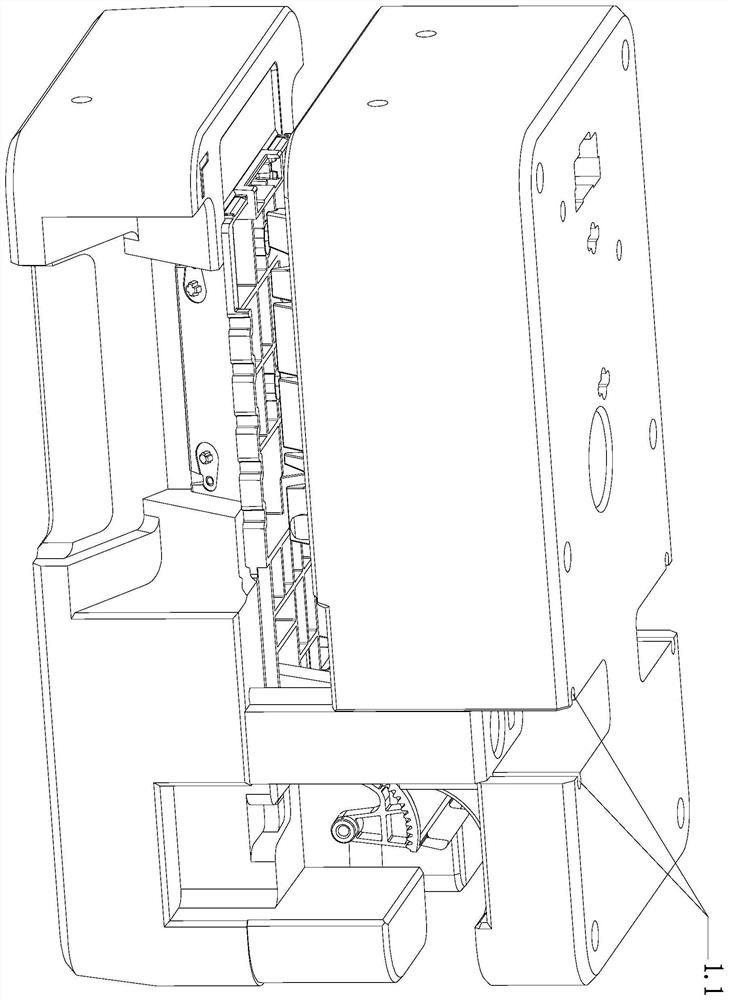

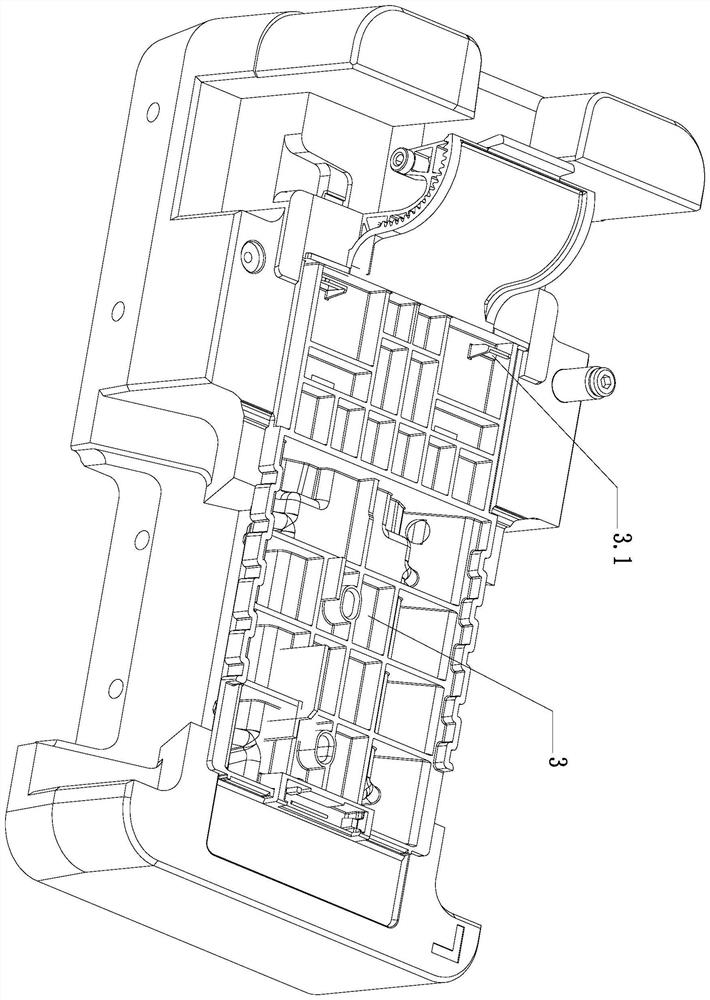

Fixed mold angle ejector inverted buckle withdrawing mechanism

A technology of withdrawing mechanism and fixed mold lifter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The drawings and the following description describes the preferred modes of the present application to teach how the best modes of the art will be manufactured and used in the art. In order to teach the principles of the invention, some conventional aspects have been simplified or omitted. Those skilled in the art will appreciate that the variations from these examples fall within the scope of the present invention. Those skilled in the art will appreciate that the following features can be combined in a variety of ways to form a plurality of variations of this application. Thus, the present application is not limited to the specific embodiments described below, but is limited only by the claims and their equivalents.

[0020] It should be noted that all directional indications (such as above, lower, left, right, front, and then ...) are intended to be interpreted between the components under a particular attitude (as shown in the drawings). The relative positional relation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com