Method for manufacturing injection product model

A technology for injection molding products and manufacturing methods, which is applied in the field of precision integrated injection molding product model production based on fitting and positioning anti-deformation processing, which can solve problems such as inaccurate positions, difficult data point processing, and easy deformation of products, so as to improve product manufacturing speed , shorten the product handover time, improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

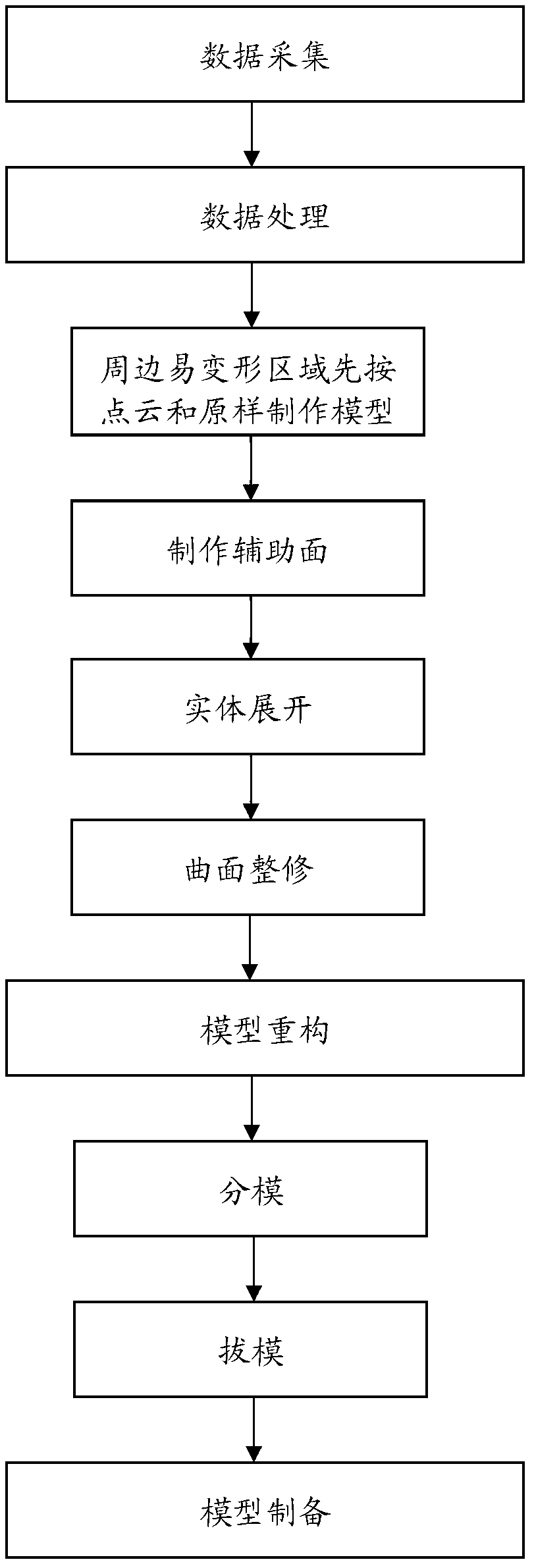

[0022] Such as figure 1 As shown, the integrated injection molding product design method of the present invention includes the following steps:

[0023] (1) Data acquisition, including scanning of samples, for the deep and narrow part of the groove, it is first bent to deformation and then three-coordinate laser scanning, firstly uses three-point positioning in space to find the reference, and then scans the front and back lasers and collects data; the three-point positioning Finding the reference is to stick three balls anywhere around the product before laser scanning, and then laser scan the front and back of the product including the glued balls; the reference is the center point of the three balls; The benchmark error is controlled at 0.005-0.01.

[0024] (2) Data processing, for the deformable area around the product, follow the steps below:

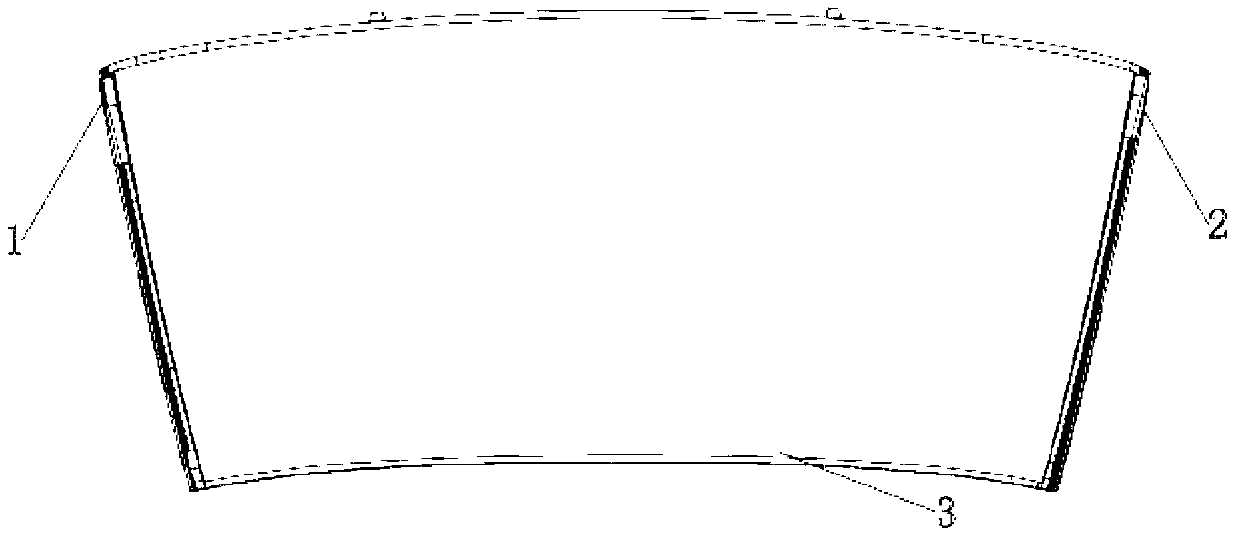

[0025] 1) Corresponding to the easily deformable area around the product, the original point cloud model is obtained by laser s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com