Technology for holding pressure control according to melting body temperature as injection molding machine

A technology of melt temperature and injection molding machine, which is applied in the technical field of injection molding machine pressure control based on melt temperature, can solve problems such as low repeatability, unstable product quality, equipment investment, and increased production cost, and achieve product quality and the effect of improved repeatability

Inactive Publication Date: 2010-04-28

ZHEJIANG KEQIANG INTELLIGENT CONTROL SYST

View PDF0 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The conventional way of improving product quality and repeatability is to use precision injection molding machines and precision molds for production, but this will lead to a substantial increase in equipment investment and production costs

An effective way to improve the quality and repeatability of products is to improve the pressure-holding link that is most closely related to the product forming process. The existing pressure-holding control technology is controlled according to position and time, which is an open-loop control Molding process, there are problems such as unstable product quality and low repeatability

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

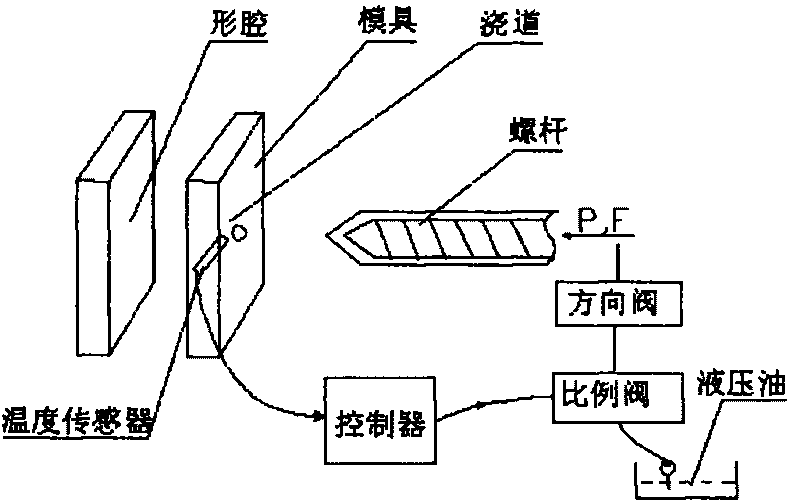

[0009] exist figure 2 In the process, a melt temperature sensor is installed on the cavity or runner of the mold to measure the melt temperature; the signal output of the sensor is connected to the controller of the injection molding machine, and the output of the controller drives and controls the hydraulic components to adjust the injection and pressure holding actions. pressure.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

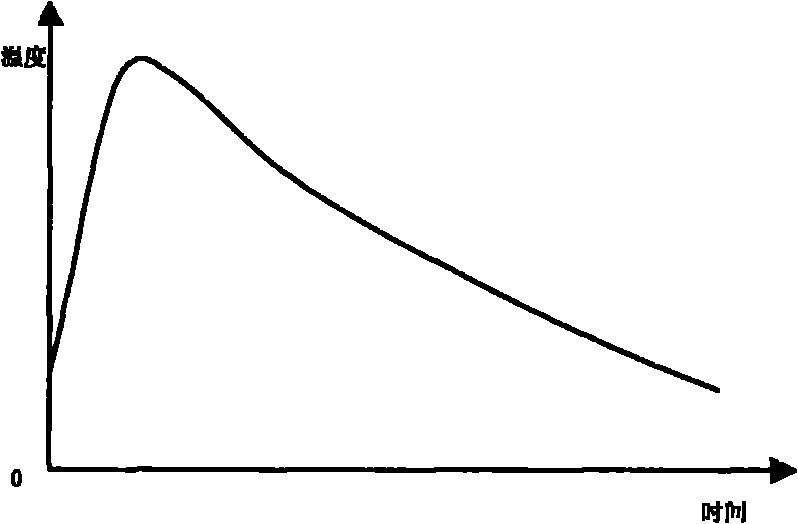

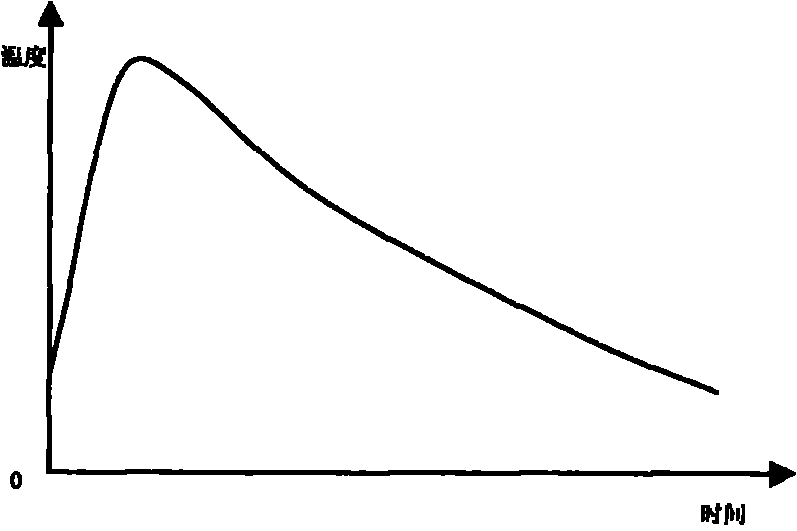

The invention discloses a technology for holding pressure control according to melting body temperature as an injection molding machine, comprising the following technical steps: A), installing a melting body temperature sensor on the mould cavity or pouring gate of an injection machine for measuring the melting body temperature; B), connecting the output signal of the melting body temperature sensor to an injection machine controller; C), writing the holding pressure control procedure in the injection machine controller as the holding pressure switch according to the melting body temperature; D), in the injection holding pressure process, the melting body temperature in the mould cavity is quickly increased firstly and slowly reduced then, after the temperature reaches the top point, the invention performs transfer holding pressure, holding pressure switch and holding pressure end control according to the set melting body temperature. The invention has the advantages of high injection product quality and repeat accuracy.

Description

【Technical field】 [0001] The present invention relates to a control process for pressure-holding control of plastic products produced by injection molding machines, more specifically, it relates to a control method for pressure-holding control process, which can improve the quality and repeatability of injection products of injection molding machines . 【Background technique】 [0002] As a main processing molding process, injection molding has the advantages of easy large-scale production, light weight, stable structure and low price. With the rapid development of my country's plastics industry, higher requirements are put forward for the quality and repeatability of injection products. The conventional way of improving product quality and repeatability is to use precision injection molding machines and precision molds for production, but this will lead to a substantial increase in equipment investment and production costs. An effective way to improve the quality and repeat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B29C45/76B29C45/77B29C45/78

Inventor 陈小强章锦雷

Owner ZHEJIANG KEQIANG INTELLIGENT CONTROL SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com