Elevator sliding guide shoe and machining process thereof

A technology for sliding guide shoes and elevators, which is applied in elevators, transportation and packaging, etc. It can solve problems such as inconvenient disassembly, detachment of shoe linings, excessive friction between sliding guide shoes and guide rails, etc., so as to facilitate disassembly and replacement, improve firmness, and avoid overall detachment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

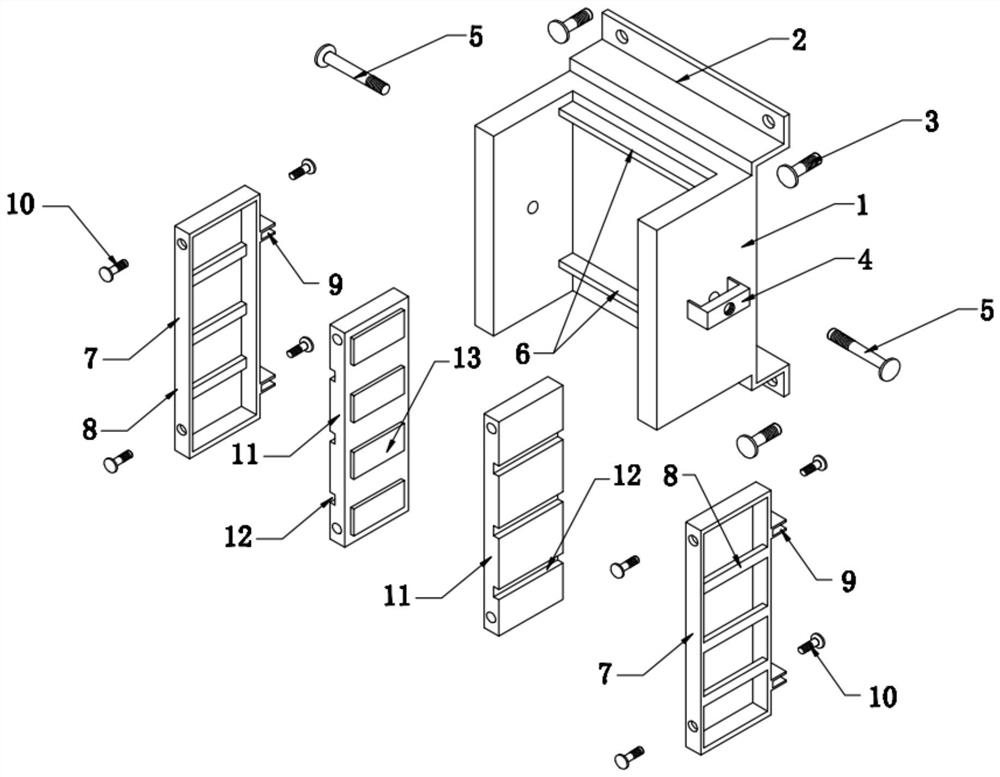

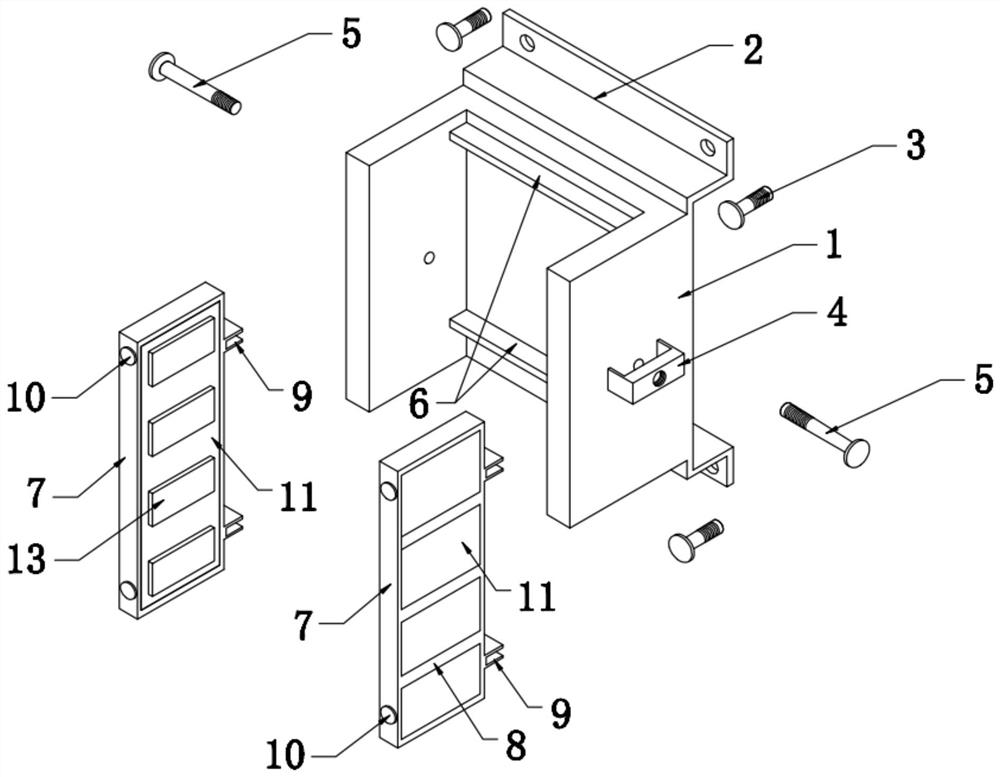

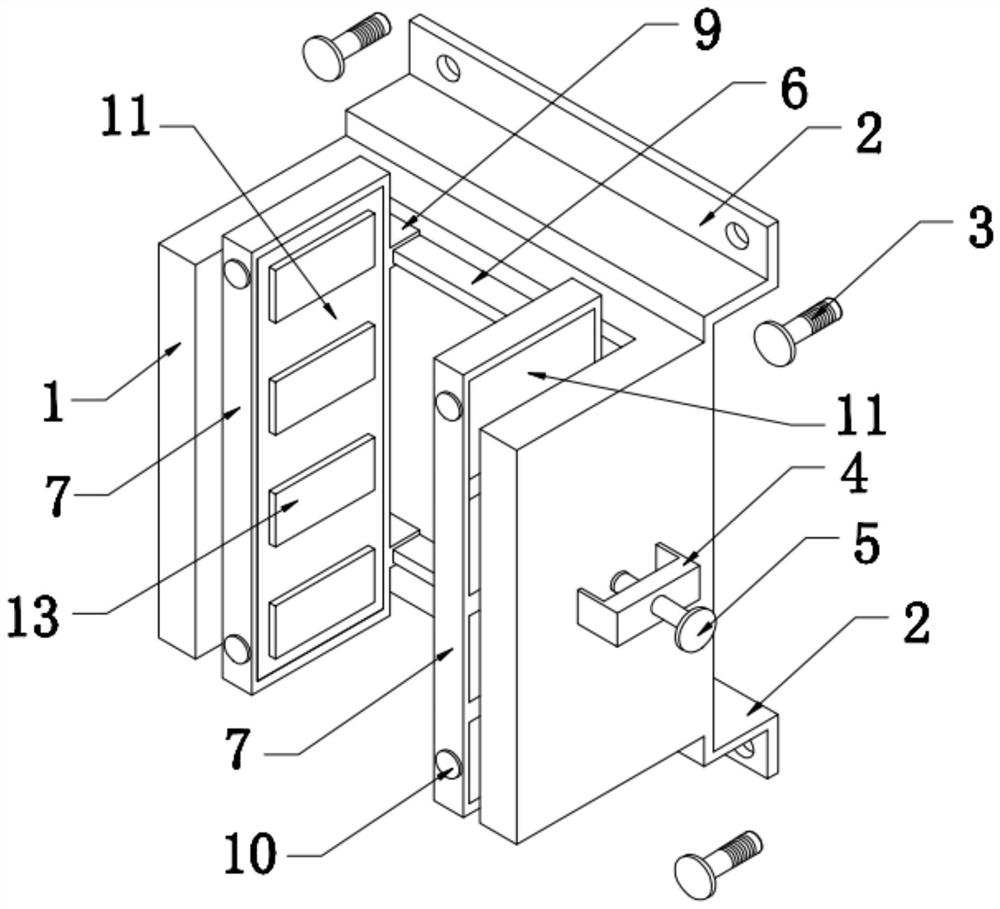

[0021] Embodiment 1: the present invention provides such as Figure 1-3 A sliding guide shoe for an elevator, comprising a shoe base 1, two sets of left and right installation frames 7 and shoe linings 11, the upper and lower parts of the inner rear side wall of the shoe base 1 are provided with slide rail plates 6, and the upper and lower parts of the installation frame 7 The upper and lower parts of the rear side are provided with a chute seat 9, and the chute seat 9 is slidably connected to the corresponding slide rail plate 6;

[0022] The inner side of the installation frame 7 is provided with several groups of stiffeners 8, the shoe lining 11 is stuck inside the installation frame 7, and the first bolt 10 on the side of the installation frame 7 is screwed to the shoe lining 11, so that The inner surface of the shoe lining 11 is provided with several sets of shoe lining protrusions 13 integrally formed therewith, and the shoe lining protrusions 13 are arranged equidistant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com