All-terrain multi-functional pipe lifting machine based on excavator platform

An all-terrain, multi-function technology, applied in mechanically driven excavators/dredgers, cranes, etc., can solve the problems of small chassis ground clearance, single function, poor stability of the whole machine, etc., to improve practicability and enhance function performance, improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

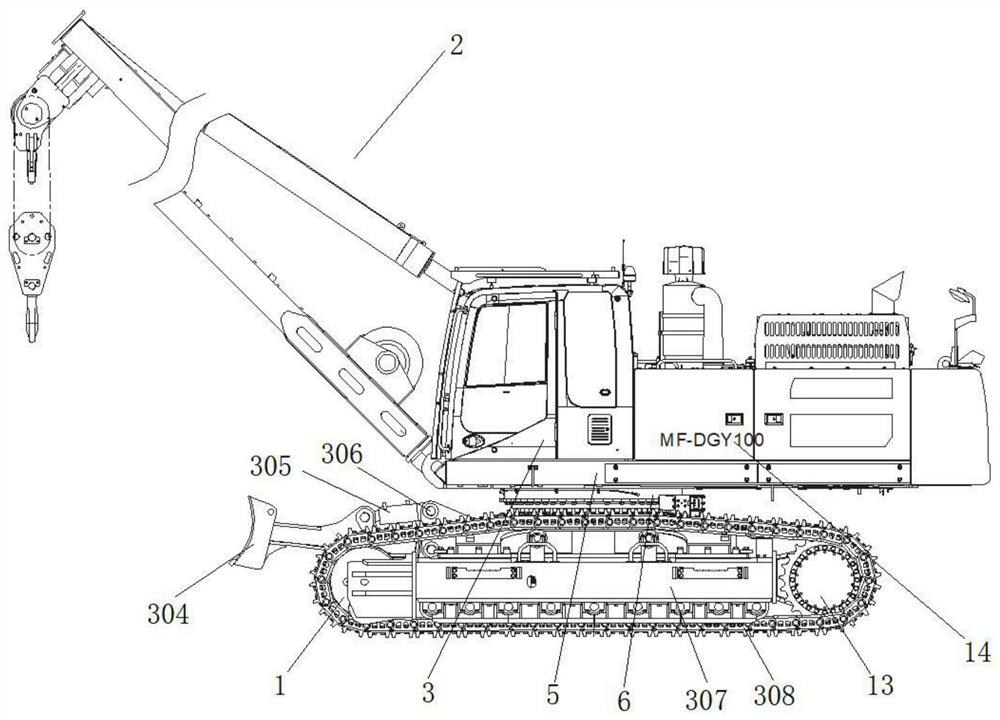

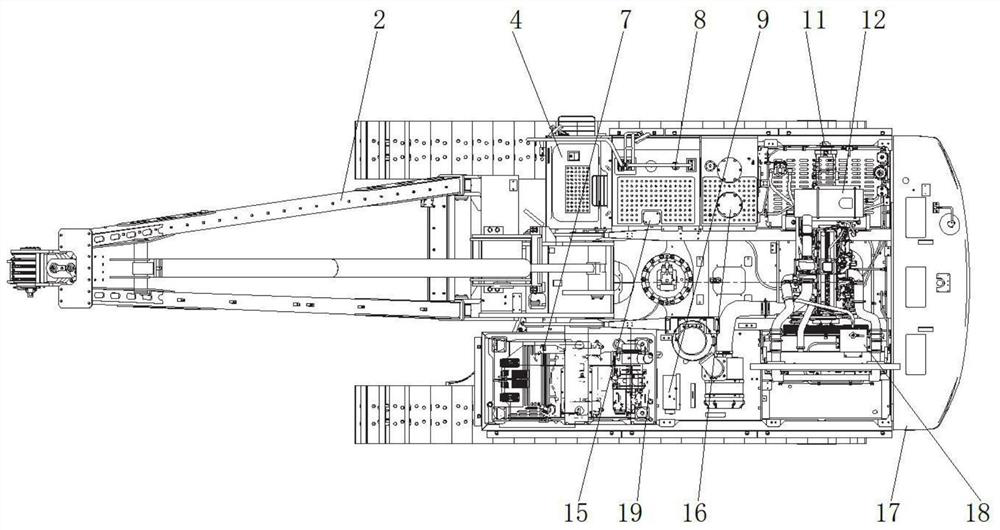

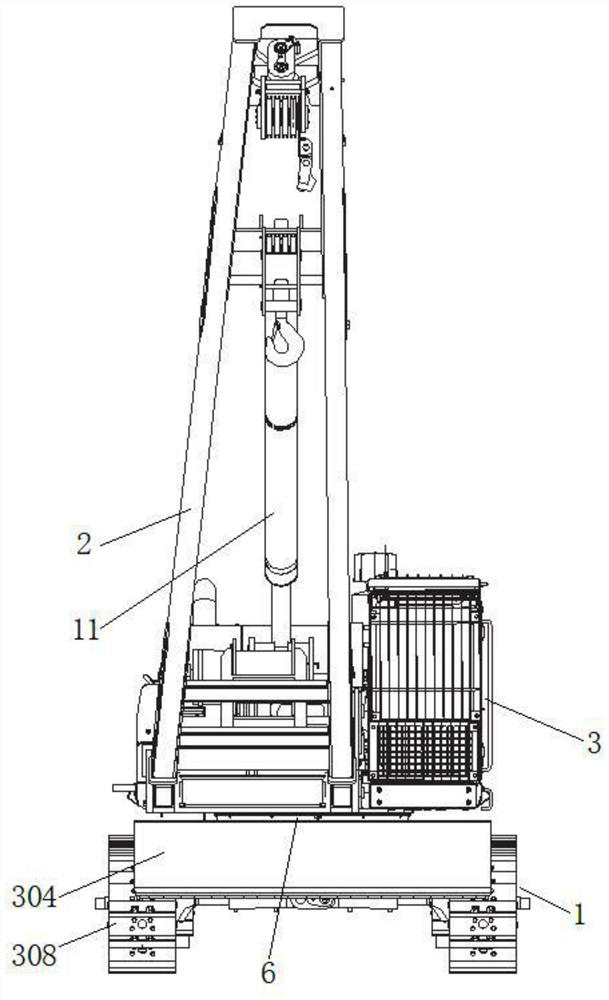

[0038] see Figure 1-9 , an all-terrain multifunctional pipelayer based on an excavator platform, comprising a chassis assembly 1, a pipehanging working device 2, a turntable assembly 5 and a slewing mechanism 6, and a pipehanging working device is fixedly installed on the upper end surface of the chassis assembly 1 Device 2, cab 3, tool box 4, turntable assembly 5 and slewing mechanism 6, chassis assembly 1 and turntable assembly 5 are connected with slewing mechanism 6, turntable assembly 5 is connected with connector 102 through connecting pin 101, The front end of the connector 102 is connected with the boom and the lifting system 103, and the front end of the connector 102 and the root of the boom and the lifting system 103 are connected with the luffing cylinder 104. 5-phase connection, the chassis assembly 1 is equipped with a track-changing oil cylinder 303, and the two ends of the track-changing oil cylinder 303 are respectively connected with a vehicle frame 301 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com