Injection molding mold for dosing injection part of infusion apparatus

A technology of injection molding and injection parts, which is applied in the field of medical devices, can solve the problems such as the inability to discharge air bubbles, and achieve the effects of long service life, high efficiency, and smooth and beautiful appearance of products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

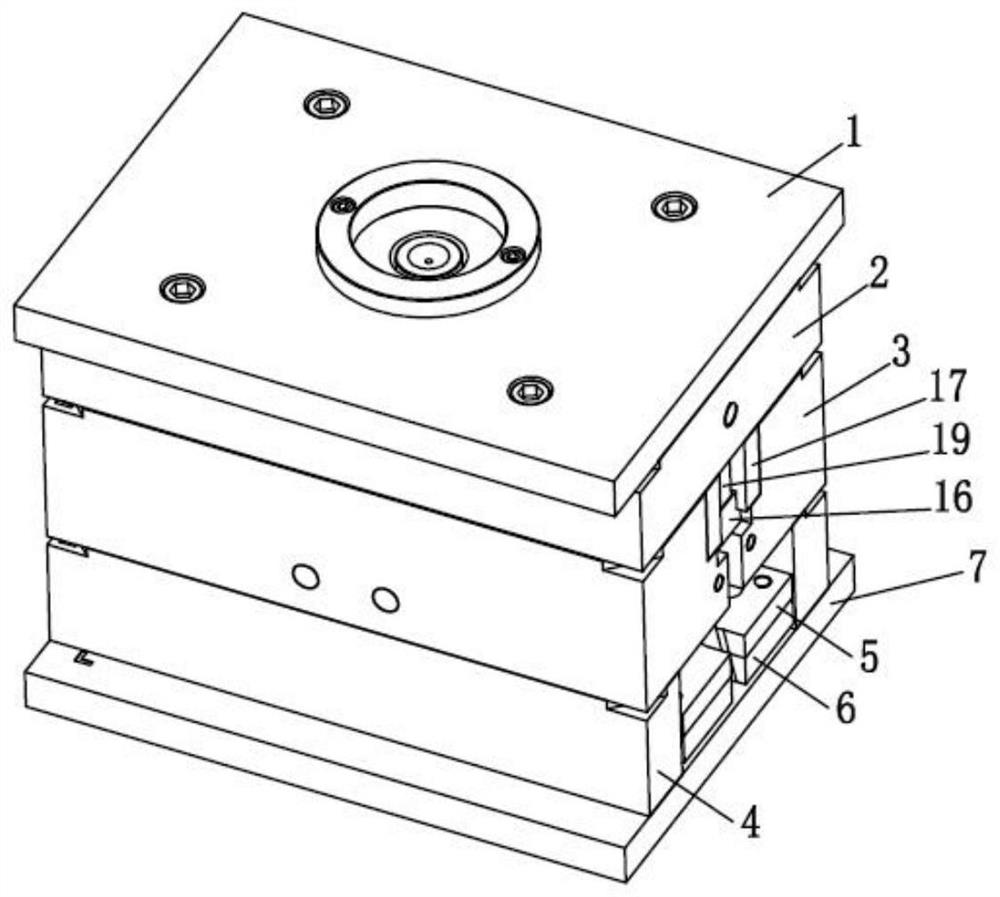

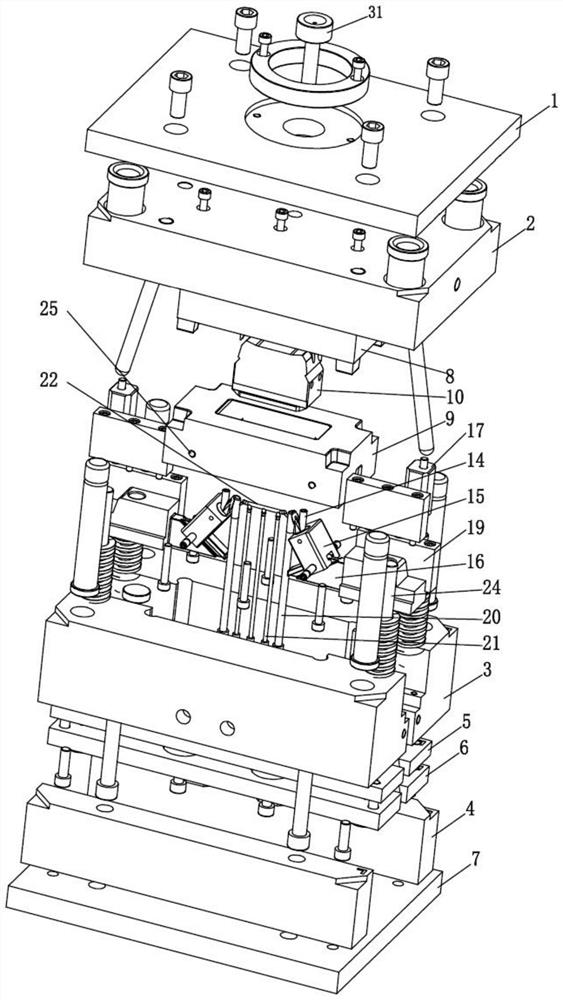

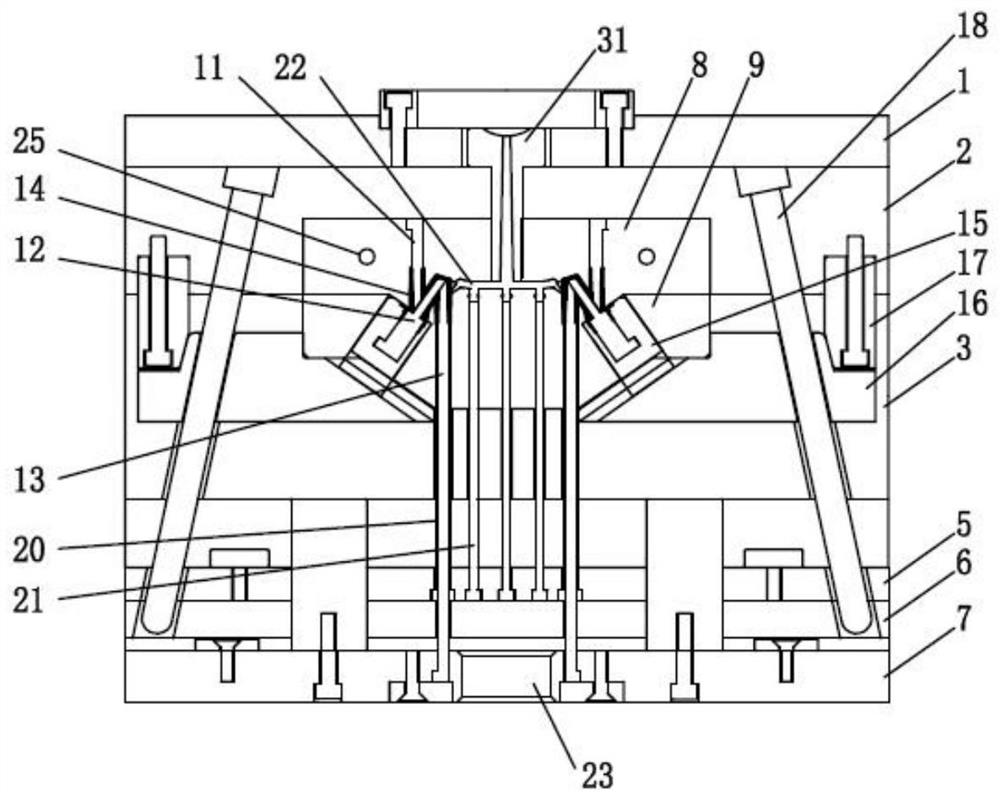

[0036] see Figure 1 to Figure 4 , an injection molding mold for injection parts of infusion sets provided in an embodiment of the present invention, including an upper fixing plate 1, a female template 2, a male template 3, and two mold feet arranged in sequence from top to bottom 4 and the lower fixing plate 7, an upper ejector plate 5 and a lower ejector plate 6 are stacked between the two mold feet 4, the upper ejector plate 5 and the lower ejector plate 6 are fixed as one, and can be fixed on the lower Move up and down between the board 7 and the male template 3;

[0037] The bottom of the female template 2 is provided with a first injection molding assembly set downwards, the male template 3 is provided with a second injection molding assembly arranged obliquely upwards, and the lower fixing plate 6 is provided with a third injection molding assembly set upwards. assembly, the end of the third injection molding assembly is in close contact with the end of the second inj...

Embodiment 2

[0060] see Figure 5 and Figure 6 , in this embodiment, the end face of the male template 3 is provided with a spacer 26, and the spacer 26 is provided with an oil cylinder 27, and the end of the piston rod of the oil cylinder 27 passes through the spacer 26 and the spacer. The slider seat 16 is connected, that is, the sliding of the slider seat 16 is realized by an oil cylinder 27 .

[0061] Specifically, in this embodiment, since the movement stroke of the oil cylinder 27 can be very large, the movement stroke of the slider seat 16 can be adjusted by directly adjusting the oil cylinder 27 or replacing the oil cylinder 27, and the non-oil cylinder structure needs to be re-modified and processed many mold parts. Accessories; through the oil cylinder 27, it is more convenient to control the time and direction of the movement of the slider seat 16 (such as directly adjusting the installation direction of the oil cylinder 27), instead of the oil cylinder structure, various obli...

Embodiment 3

[0071] see Figure 7 , in this embodiment, a male mold carrier plate 28 is provided between the male template 3 and the upper ejector plate 5, and the bundle block 17a is fixed in the through hole of the male mold carrier plate 28, and the male mold carrier plate The angle pin 18a that is arranged obliquely upward is provided with in the oblique hole of 28;

[0072] The bottom of the female template 2 is provided with a shutter 29, and the bottom of the shutter 29 extends into the male template 3, and the shutter 29 is used to control the order of opening between each template when the mold is opened. When the mold is opened, the male template 3 and the female template 2 are pulled, so that the female template 2 drives the male template 3 to move, so that the gap between the male template 3 and the male mold carrier plate 28 is opened first, and the male mold carrier plate 28 drives the beam block 17a and the slider The insert 15a is separated, and at the same time, the corne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com