Small metal tight etching machine convenient to adjust height

A technology for adjusting the height and etching machine, which is applied in the field of etching machines, can solve problems such as danger, time wasting, and reduce the work efficiency of staff, and achieve the effect of easy adjustment and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

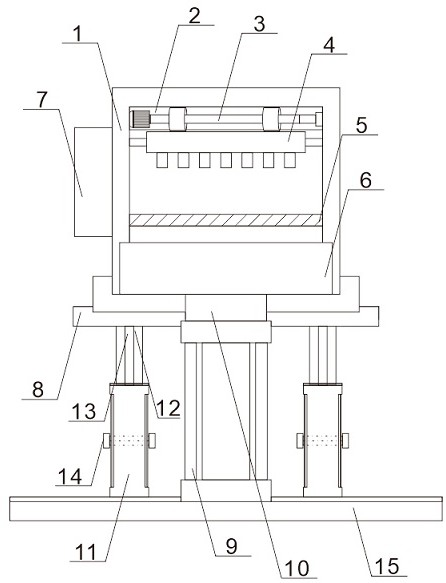

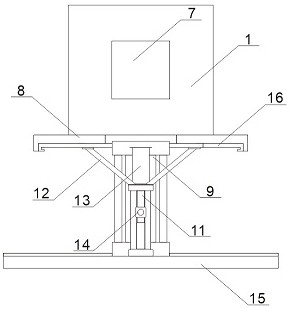

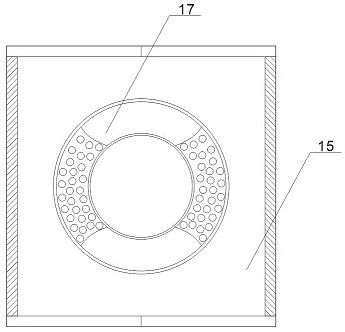

[0017] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, so as to make it easier to understand and grasp. The fuselage 1, etching chamber 2, transmission mechanism 3, spray pipe 4, etching plate 5, liquid storage tank 6 and control box 7 and other components involved are commonly used by those of ordinary skill in the art. There are no special requirements in this case.

[0018] Such as figure 1 and figure 2 As shown, a small metal compact etching machine that is convenient for height adjustment includes a fuselage 1, an etching chamber 2 is provided inside the fuselage 1, and a control box 7 is provided on one side of the fuselage 1, and the top of the etching chamber 2 is installed There is a transmission mechanism 3, and the etching plate 5 provided inside the etching chamber 2 is slidably connected with the left and right side walls of the etching chamber 2, wherein the left and right symmetric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com