Multi-station expandable equipment based on plastic injection mold transportation

An injection mold and multi-station technology, which is applied in the field of multi-station expandable equipment for transportation based on plastic injection molds, can solve problems such as poor adjustable performance, difficulty in mold disassembly, installation and transportation, and extended use of transport vehicles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

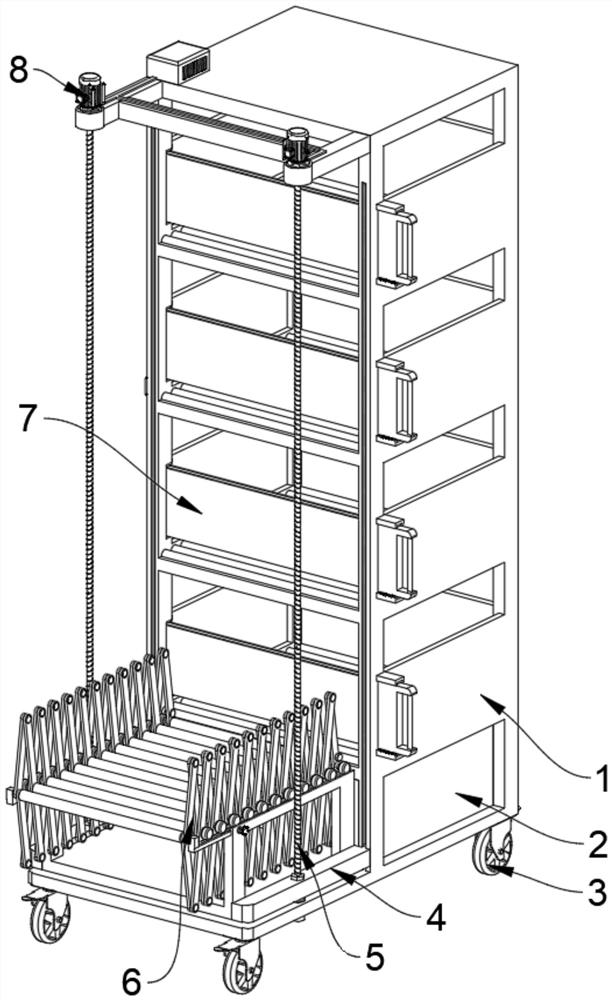

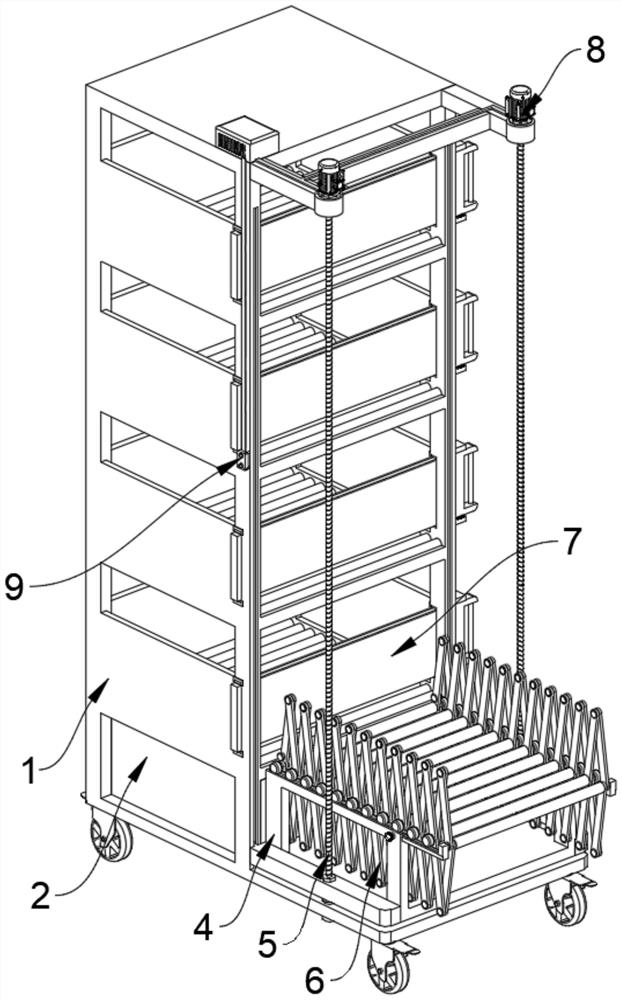

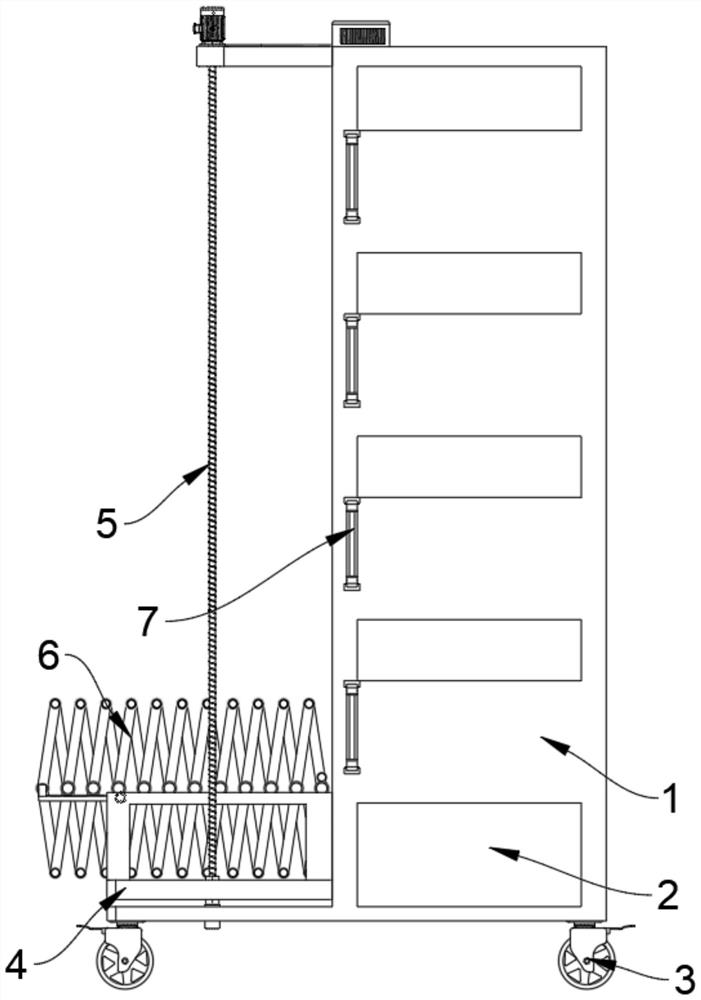

[0042] as attached figure 1 To attach Figure 12 Shown:

[0043] The present invention provides a multi-station expandable equipment for transport based on plastic injection molds, which includes: a transport carrier body 1; four moving wheels 3 with locking functions are arranged symmetrically on the bottom side of the transport carrier body 1; The storage battery 2 is fixedly installed in the bottom tank of the transport carrier body 1; the top side of the transport carrier body 1 extends forward and there are two drive motors 8 fixed on the frame body, and the two drive motors 8 are designed for synchronous drive structure; A controller 9 is also fixedly arranged on the frame side wall of the transport carrier body 1, and the controller 9 is electrically connected to the drive motor 8; There is a lifting frame 4, and two lifting screws 5 are rotated on the frame body extending forward from the bottom side of the transport carrier body 1, and the top of the lifting screw r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com