Novel hydraulic excavator piling device

A technology of hydraulic excavator and piling device, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc., and can solve the problems of small actual depth of soil pile pit, soil falling, loose soil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] For example figure 1 -example Figure 5 Shown:

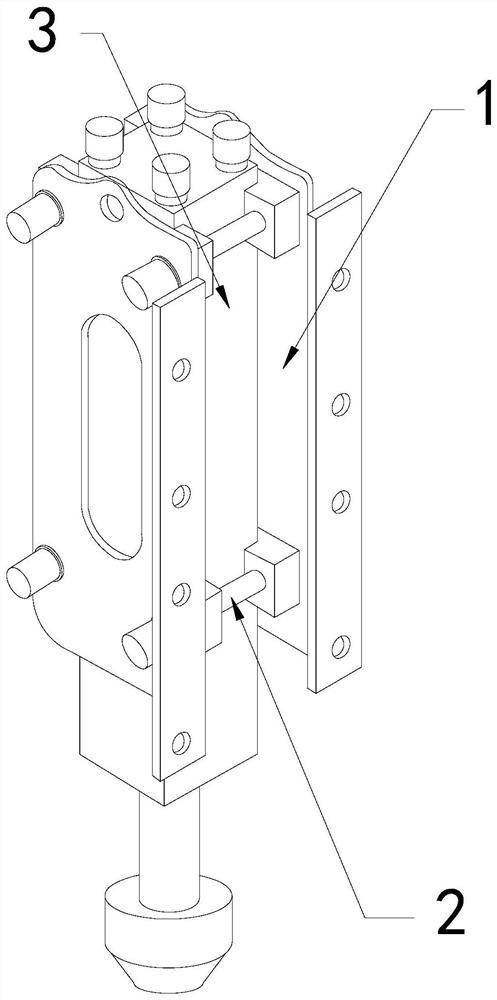

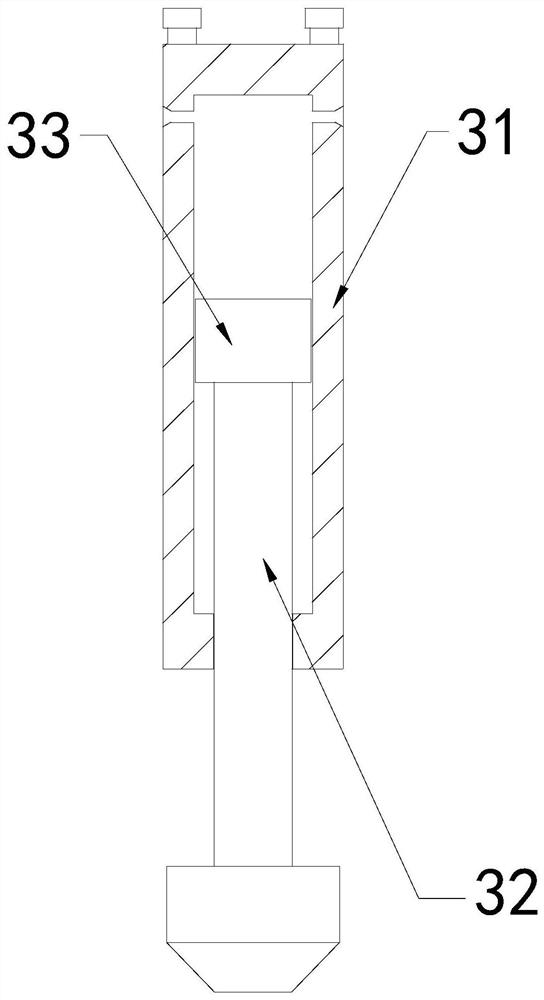

[0027] The present invention provides a new hydraulic excavator piling device, the structure of which includes an outer frame 1, a fixing screw 2, and a piling mechanism 3, the fixing screw 2 is connected to the inner thread of the outer frame 1, and the piling mechanism 3 penetrates the outer frame 1; the piling mechanism 3 includes an outer frame 31, a lower pressing rod 32, and a piston 33, and the lower pressing rod 32 is engaged with the inside of the outer frame 31; connected.

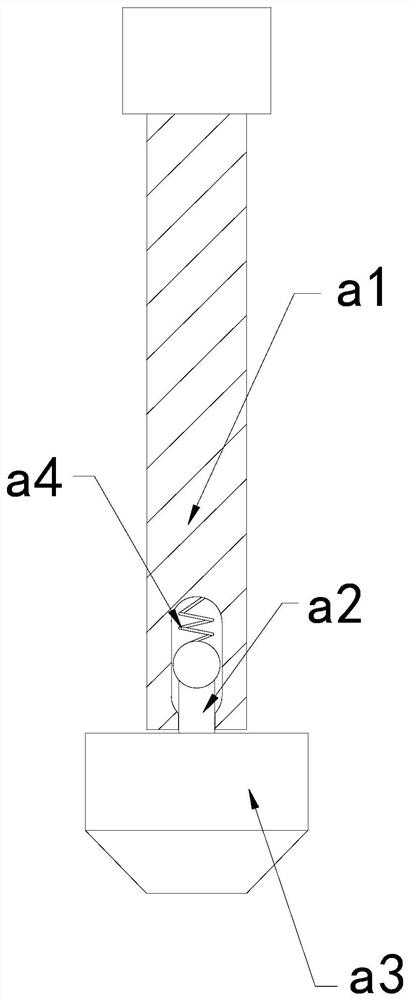

[0028] Wherein, the lower pressing rod 32 includes a rod body a1, a linkage rod a2, a bottom connecting block a3, and an elastic bar a4. The bottom of a2 fits together, and the elastic strip a4 is fixed on the upper end of the linkage rod a2 and the upper end of the inner wall of the rod body a1. Pulling the rod body a1 upwards through the mechanism can make the rod body a1 slide upward along the linkage rod a2, so that the bottom connect...

Embodiment 2

[0034] For example Image 6 -example Figure 8 Shown:

[0035] Wherein, the separating block b4 includes a rear frame b41, a sliding plate b42, and a reset bar b43, the sliding plate b42 is slidingly matched with the left side of the rear frame b41, and the reset bar b43 is installed on the inner wall of the rear frame b41 Between the sliding plate b42 and the sliding plate b42, there are two sliding plates b42, which are evenly distributed symmetrically on the left side of the rear frame b41. , the sliding plate b42 can be deployed to both sides along the rear frame b41, so that the sliding plate b42 can grind the inner wall of the soil pile pit.

[0036]Wherein, the sliding plate b42 includes a position fixing plate c1, an outer push piece c2, and an outer swing plate c3, and the outer push piece c2 is installed between the inner side of the outer swing plate c3 and the right side of the inner wall of the position fix plate c1. The outer swing plate c3 is hinged to the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com