Multi-purpose rubber hose knitting machine and rubber hose production method

A technology of braiding machines and rubber hoses, which is applied in applications, household appliances, tubular objects, etc., can solve the problems of low operating rate, equipment operating rate, and low input and output, and achieve the effect of avoiding insufficient cooling power and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

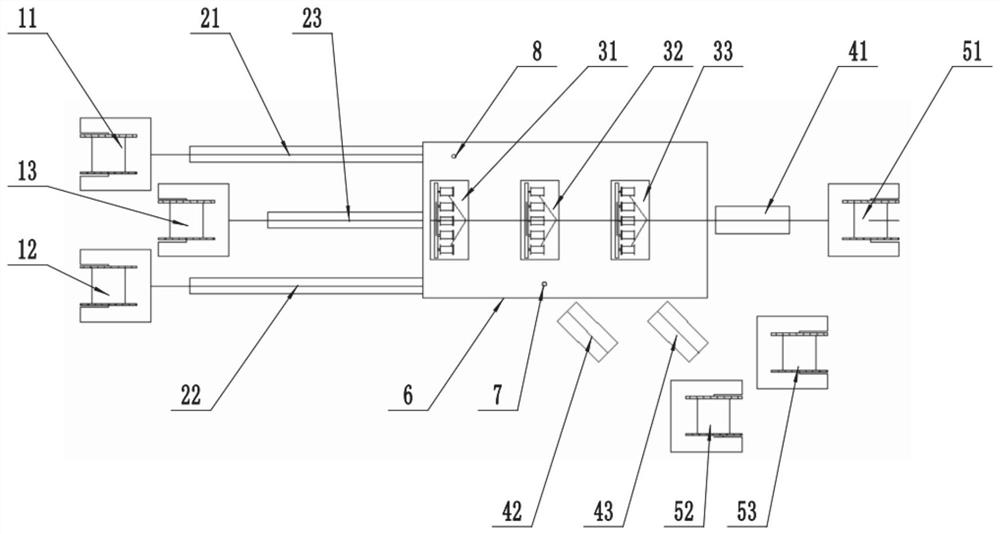

[0037] In a typical implementation of the present invention, this embodiment discloses a multi-purpose rubber hose braiding machine, including a first unwinding frame 11, a second unwinding frame 12, a third unwinding frame 13, a first freezing chamber 21, The second freezing chamber 22, the third freezing chamber 23, the first braiding platter 31, the second braiding platter 32, the third braiding platter 33, the first tractor 41, the second tractor 42, the third tractor 43, the first The winding frame 51, the second winding frame 52 and the third winding frame 53 determine the front and rear directions based on the running direction of the coiled pipe steel wire. Chamber 21, the second freezer compartment 22 is set in front of the second unwinding rack 12, the third freezer compartment 23 is set in front of the third unwinding rack 13, the first freezer compartment 21, the second freezer compartment 22 and the third freezer compartment 23 A soundproof chamber 6 is also set i...

Embodiment 2

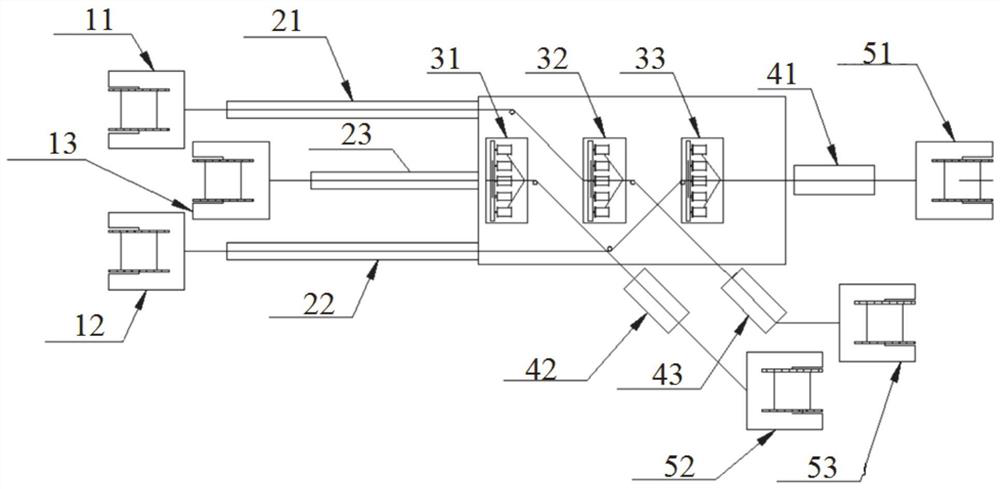

[0043] In a typical implementation of the present invention, this embodiment discloses a method for weaving a three-layer rubber hose, using the multi-purpose rubber hose braiding machine as described in Example 1, such as figure 1 As shown, the rubber hose drum is installed on the third unwinding frame 13, passes through the third freezer chamber 23, and then weaves through the first braiding tray 31, the second braiding tray 32 and the third braiding tray 33, and the three braiding trays work at the same time , and the existing weaving system uses the same method. The first weaving platter 31 , the second weaving platter 32 , the third weaving platter 33 and the first tractor 41 are linked. The second tractor 42 and the third tractor 43, the second winding frame 52 and the third winding frame 53 are not used.

Embodiment 3

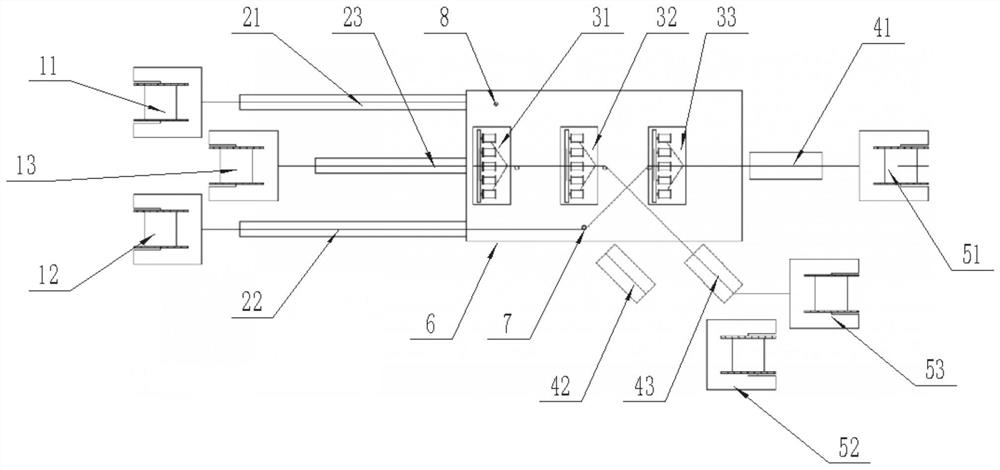

[0045] In a typical implementation of the present invention, this example discloses a method for simultaneously producing rubber hoses with different braided layers, specifically a method for simultaneously producing a two-layer braided rubber hose and a one-layer braided rubber hose, as in the example 1 The multi-purpose hose braiding machine, such as figure 2 As shown, the two-layer braided rubber hose drum is installed on the third unwinding support, enters the first weaving large plate 31 and the second weaving large plate 32 through the third freezing chamber 23, and exits from the soundproof room 6 in front of the third tractor 43 Go out and enter the third tractor 43, the rubber hose is pulled by the third tractor 43 to weave, and the third winding frame 53 is used for winding after weaving.

[0046] One layer of braided rubber hose roller is installed on the second rubber hose unwinding frame 12, the rubber hose enters the second freezing chamber 22 and then enters th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com