Energy-saving device capable of automatically adjusting humidification amount according to thickness of textile materials

A technology of automatic adjustment and humidification, which is applied in the direction of textile material equipment configuration, spray/jet textile material treatment, liquid/gas/steam removal with squeeze rollers, etc. It can solve the problems of high cost of use and troublesome textile material humidification, etc. , to achieve the effect of low production cost and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

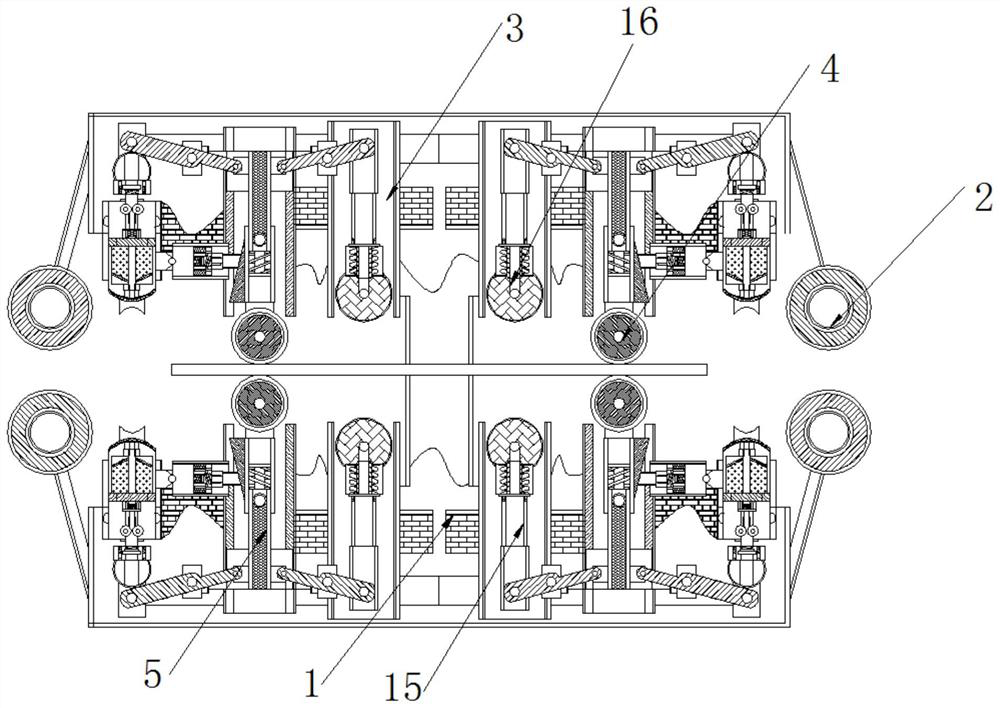

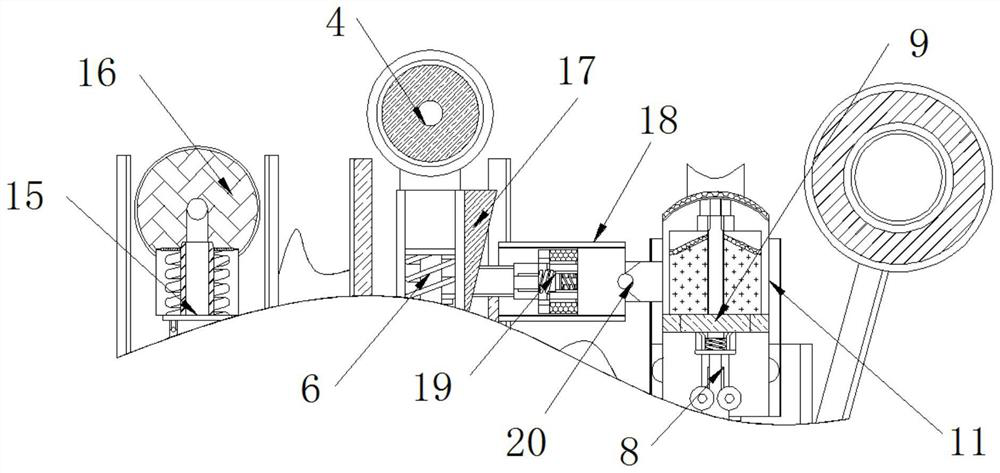

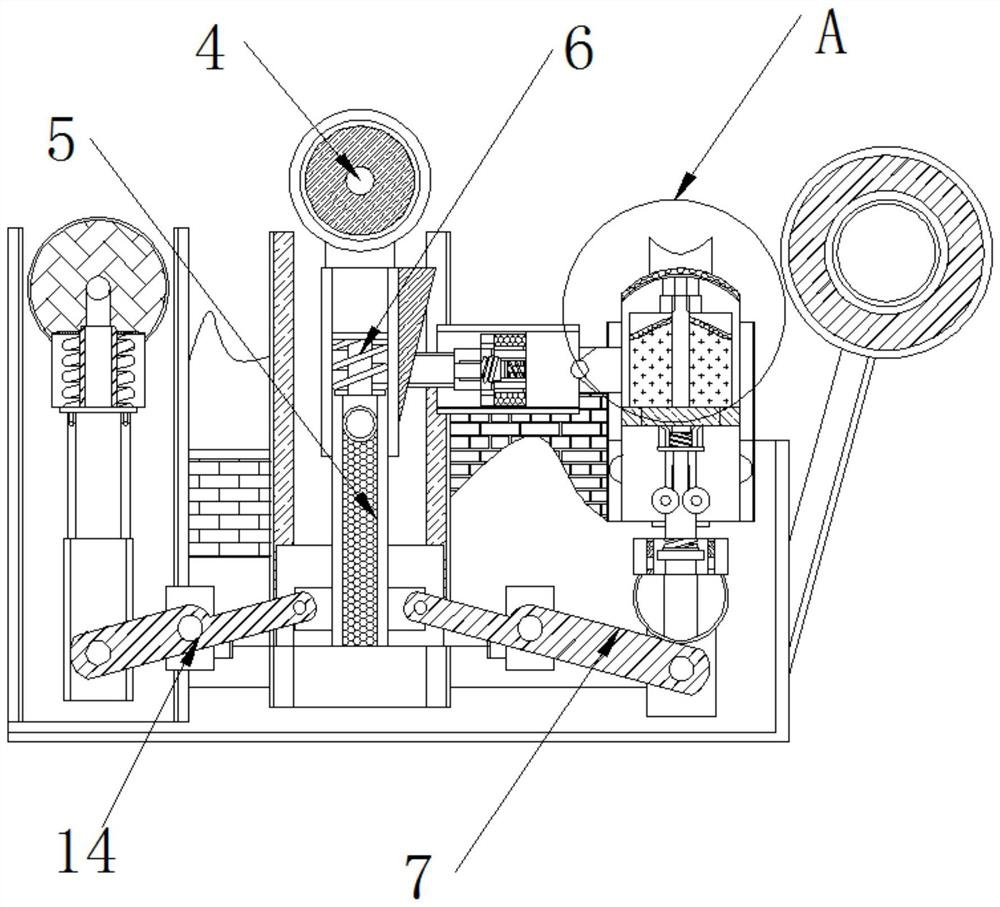

[0022] as attached figure 1 to attach Figure 5 Shown:

[0023] The invention provides an energy-saving device that can automatically adjust the humidification amount according to the thickness of the textile material. frame 3, the outer surface of the guide seat 1 is provided with a rotating shaft compatible with the guide wheel 2, and the inside of the guide seat 1 is provided with a groove compatible with the detection frame 3, and the outer surface of the detection frame 3 is movably connected with The pressure head 4, the side surface of the pressure head 4 is movably connected with the telescopic rod 5, and the contact 10 drives the arc-shaped limit plate 12 at one end to deform, and then the diameter of the water outlet hole 13 becomes larger, so that the water quality will be improved from the outlet. The hole 13 is sprayed out to achieve the effect of automatic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com