Electric insulator maintenance construction system and construction method

A technology of insulators and insulator strings, which is applied in the construction system and construction field of power insulator maintenance, can solve problems such as long working hours, damaged wire clamps, and affecting the quality of work, and achieve the effects of improving work efficiency, avoiding high-altitude operations, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

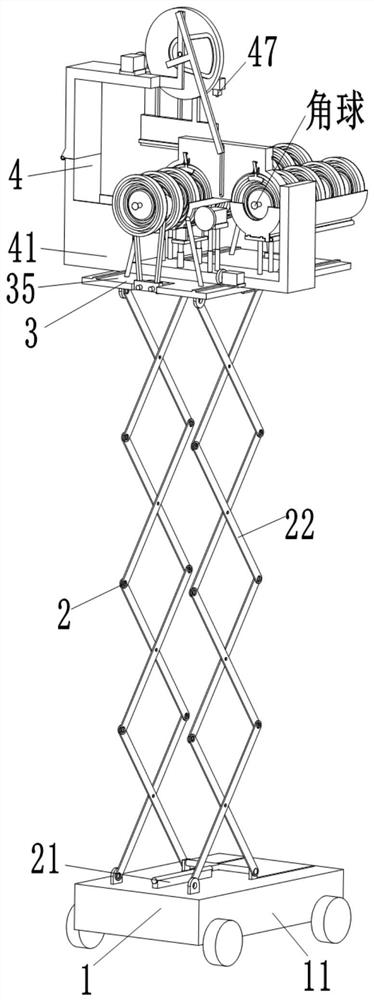

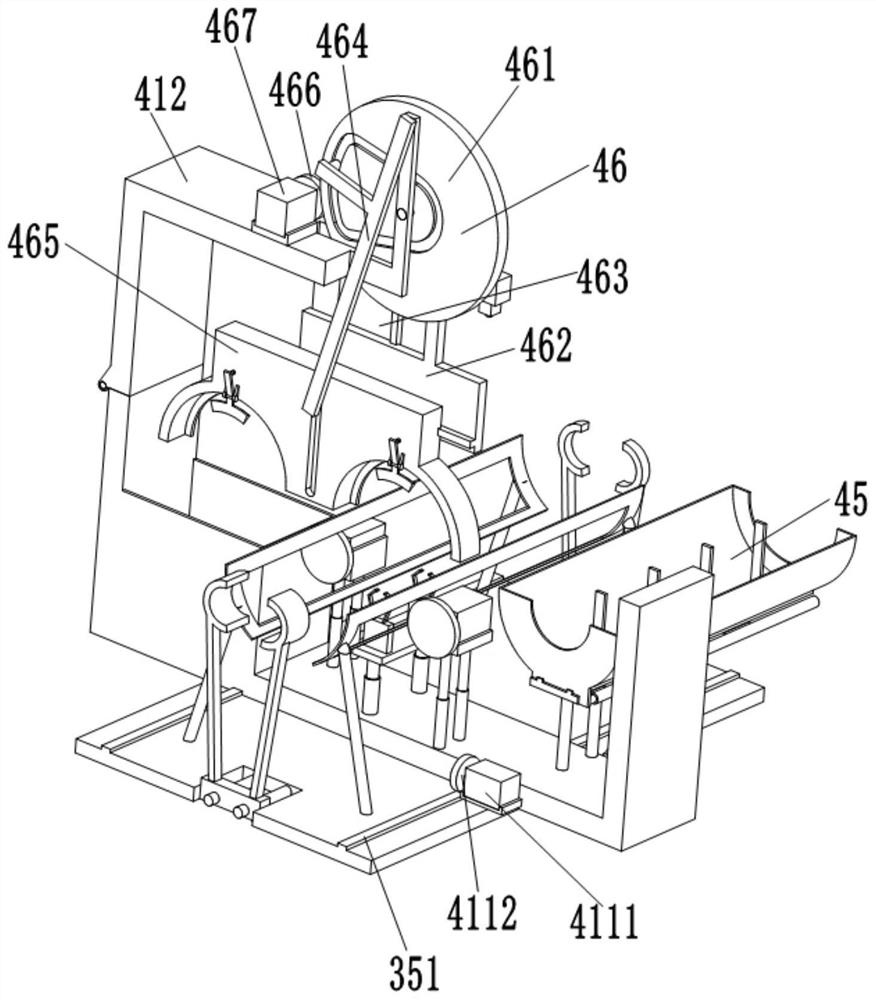

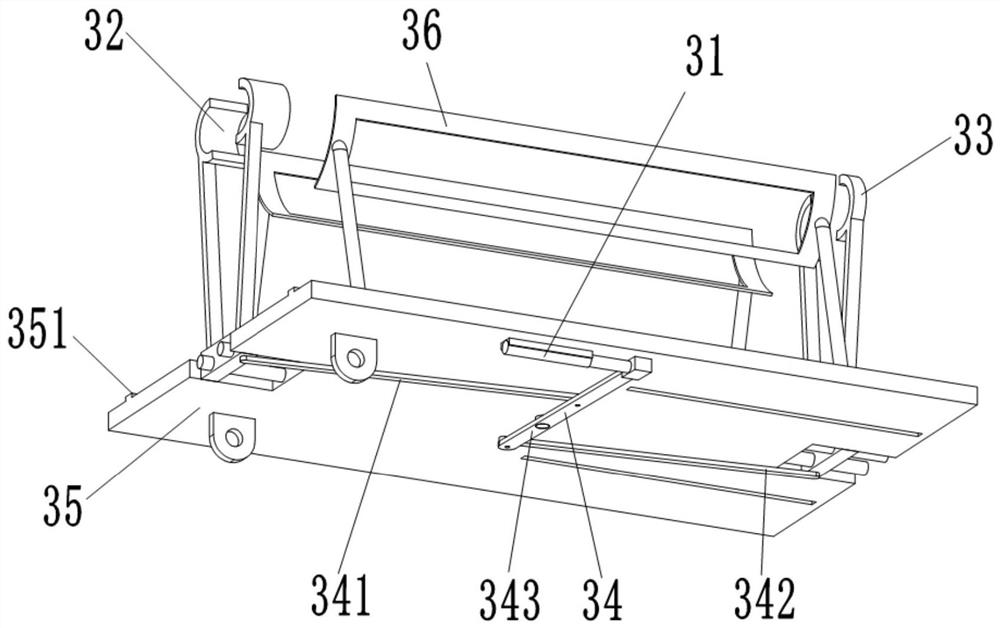

[0043] Such as Figure 1-13 Shown is a preferred embodiment of the present invention.

[0044] A power insulator maintenance and construction system, comprising a traveling mechanism 1, a lifting mechanism 2, a relaxing mechanism 3 and a replacement mechanism 4; The replacement mechanism 4 is arranged on the upper end of the relaxation mechanism 3, the traveling mechanism 1 can move the lifting mechanism 2, the relaxation mechanism 3 and the replacement mechanism 4 to the bottom of the insulator string, and the lifting mechanism 2 can move the relaxation mechanism 3 and the replacement mechanism 4. Elevate to the working height of the replacement insulator. The string of insulators to be replaced can be loosened through the release mechanism 3, so that the insulator to be replaced can be displaced relative to the adjacent insulator. The repla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com