A kind of hydrophobic gas permeable photocatalytic polymer nanocomposite film and its preparation method and application

A nano-composite, hydrophobic and breathable technology, applied in chemical instruments and methods, separation methods, semi-permeable membrane separation, etc., can solve the problems of complex preparation process, easy aging, difficulty in promotion and practical use, etc. And the effect of disinfecting, low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

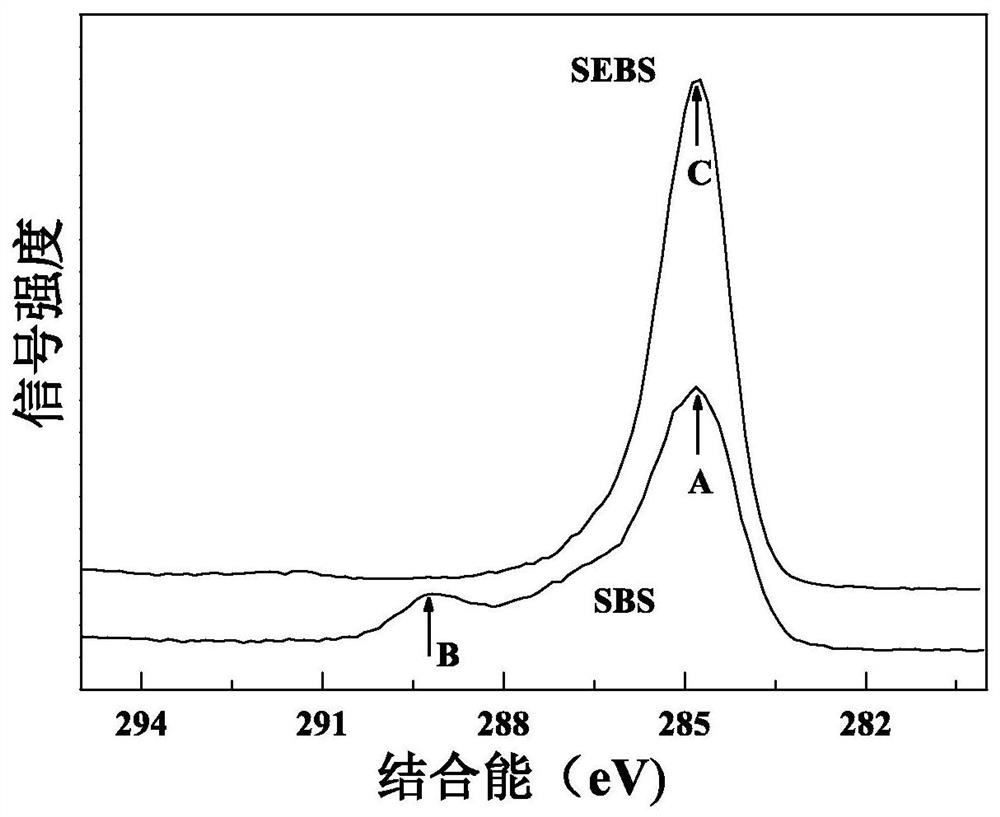

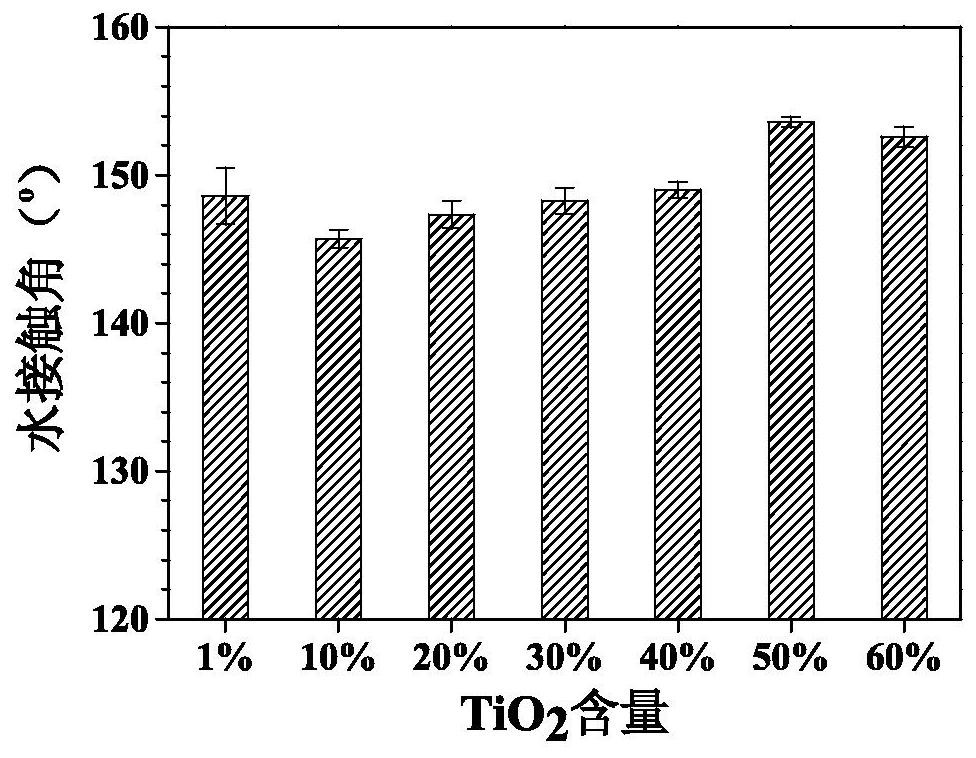

[0045] Add 40 mL of cyclohexane to 200 mg of hydrogenated styrene-butadiene-styrene triblock copolymer (SEBS), stir vigorously in an oil bath at 50 ° C for 2 h to form a light blue first micellar solution, and then add Nano-titanium dioxide of different quality was added to it, ultrasonicated vigorously for 10 minutes, and then placed in a thermostat at 50°C for 6 hours to obtain a uniform and stable mixed slurry for use. Soak the stainless steel mesh (300 mesh) substrate in the SEBS cyclohexane solution (second micellar solution) with a concentration of 100 mg / mL for 10 minutes, then take it out and dry it naturally to obtain a high-strength mesh substrate. Put the mixed slurry, high-strength mesh substrate and pneumatic spray gun into a 50°C constant temperature closed glove box filled with water vapor at the same time. Take 36mL of the mixed slurry and put it into a pneumatic spray gun, and spray the surface of the high-strength mesh substrate in a closed glove box. The spr...

Embodiment 2

[0053] According to the method of Example 1, 72 mL of SEBS cyclohexane solution (the first micellar solution) with a concentration of 100 mg / mL and a mixed slurry were prepared. The mass percentage of nano-titanium dioxide in the mixed slurry to the solid content was 50%. Immerse a 300-mesh stainless steel mesh cut to an appropriate size in SEBS cyclohexane solution (second micellar solution) with a concentration of 100 mg / mL for 5 minutes, and then evaporate the solvent naturally in the air for 1 hour to obtain a high-strength mesh substrate. The above-mentioned mixed slurry was sprayed on the high-strength mesh substrate and the stainless steel mesh respectively in an atmosphere filled with mixed steam of water and methanol (water:methanol, mass ratio 4:6) at 25°C, and then left to stand for 10 minutes to evaporate the non-volatile solvent. After the solvent vapor-induced phase separation process, two composite films were obtained. Abrasion resistance control experiment was ...

Embodiment 3

[0055] Dissolve hydrogenated styrene-isoprene-styrene triblock copolymer (SEPS) in ethyl acetate to obtain a SEPS ethyl acetate solution (first micelle solution) with a concentration of 120 mg / mL; and add Nano-titanium dioxide, the mass percentage of nano-titanium dioxide in solid content is 20%. Soak nylon mesh (400 mesh) in SEPS ethyl acetate solution (second micellar solution) with a concentration of 120 mg / mL for 5 minutes, and then evaporate the solvent naturally in the air for 1 hour to obtain a high-strength mesh substrate. Spray the above-mentioned mixed slurry on a high-strength mesh substrate in a closed atmosphere box at 5°C. The atmosphere box is pre-filled with mixed steam of ethanol and n-propanol (the mass ratio of the two is 5:5), and the solvent can be volatilized to produce get a composite film. The resulting composite film was subjected to scanning electron microscope morphology observation after gold-spraying treatment, see Figure 6 .

[0056] The compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com