Hydrophobic breathable photocatalytic polymer nano composite membrane as well as preparation method and application thereof

A nano-composite, hydrophobic and breathable technology, applied in chemical instruments and methods, separation methods, semi-permeable membrane separation, etc., can solve the problems of difficulty in popularization and practical use, easy aging, complicated preparation process, etc., and achieve low price and easy cleaning and disinfecting, the effect of a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

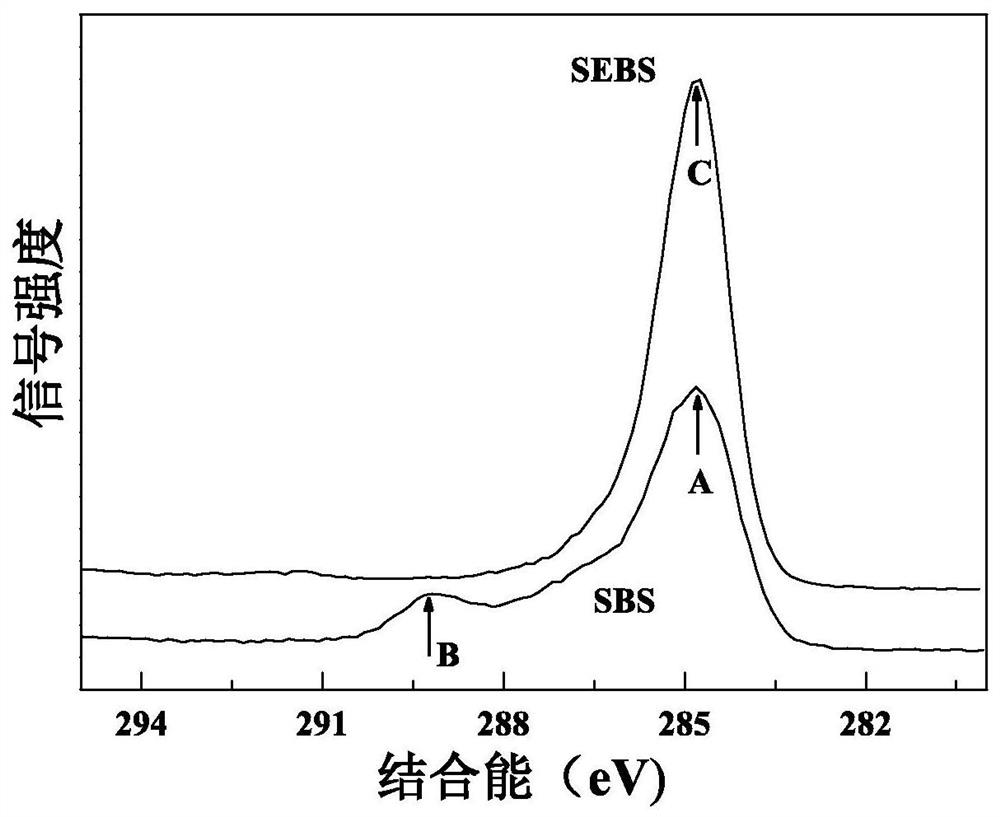

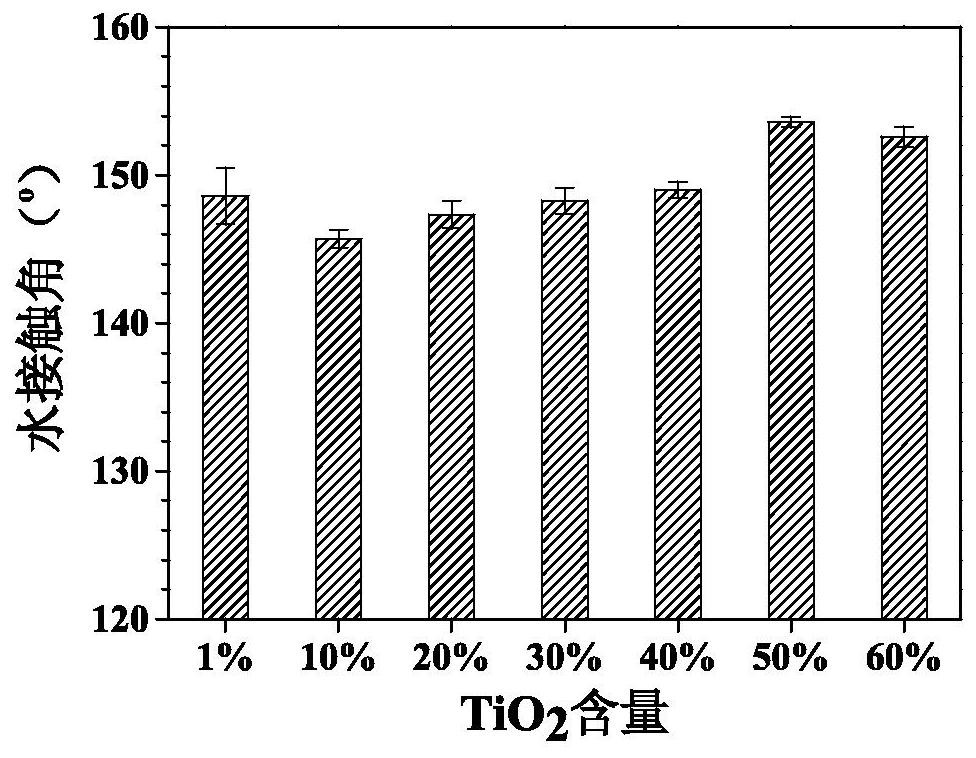

[0045] Add 40 mL of cyclohexane to 200 mg of hydrogenated styrene-butadiene-styrene triblock copolymer (SEBS), stir vigorously in an oil bath at 50 ° C for 2 h to form a light blue first micellar solution, and then add Nano-titanium dioxide of different quality was added to it, ultrasonicated vigorously for 10 minutes, and then placed in a thermostat at 50°C for 6 hours to obtain a uniform and stable mixed slurry for use. Soak the stainless steel mesh (300 mesh) substrate in the SEBS cyclohexane solution (second micellar solution) with a concentration of 100 mg / mL for 10 minutes, then take it out and dry it naturally to obtain a high-strength mesh substrate. Put the mixed slurry, high-strength mesh substrate and pneumatic spray gun into a 50°C constant temperature closed glove box filled with water vapor at the same time. Take 36mL of the mixed slurry and put it into a pneumatic spray gun, and spray the surface of the high-strength mesh substrate in a closed glove box. The spr...

Embodiment 2

[0053] According to the method of Example 1, 72 mL of SEBS cyclohexane solution (the first micellar solution) with a concentration of 100 mg / mL and a mixed slurry were prepared. The mass percentage of nano-titanium dioxide in the mixed slurry to the solid content was 50%. Immerse a 300-mesh stainless steel mesh cut to an appropriate size in SEBS cyclohexane solution (second micellar solution) with a concentration of 100 mg / mL for 5 minutes, and then evaporate the solvent naturally in the air for 1 hour to obtain a high-strength mesh substrate. The above-mentioned mixed slurry was sprayed on the high-strength mesh substrate and the stainless steel mesh respectively in an atmosphere filled with mixed steam of water and methanol (water:methanol, mass ratio 4:6) at 25°C, and then left to stand for 10 minutes to evaporate the non-volatile solvent. After the solvent vapor-induced phase separation process, two composite films were obtained. Abrasion resistance control experiment was ...

Embodiment 3

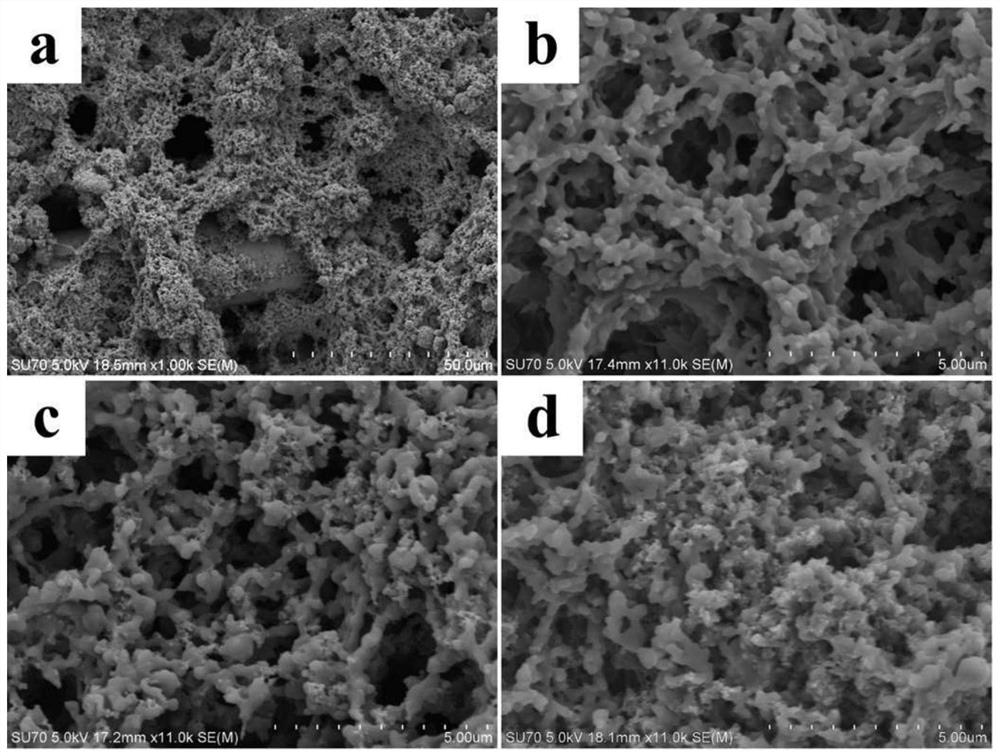

[0055] Dissolve hydrogenated styrene-isoprene-styrene triblock copolymer (SEPS) in ethyl acetate to obtain a SEPS ethyl acetate solution (first micelle solution) with a concentration of 120 mg / mL; and add Nano-titanium dioxide, the mass percentage of nano-titanium dioxide in solid content is 20%. Soak nylon mesh (400 mesh) in SEPS ethyl acetate solution (second micellar solution) with a concentration of 120 mg / mL for 5 minutes, and then evaporate the solvent naturally in the air for 1 hour to obtain a high-strength mesh substrate. Spray the above-mentioned mixed slurry on a high-strength mesh substrate in a closed atmosphere box at 5°C. The atmosphere box is pre-filled with mixed steam of ethanol and n-propanol (the mass ratio of the two is 5:5), and the solvent can be volatilized to produce get a composite film. The resulting composite film was subjected to scanning electron microscope morphology observation after gold-spraying treatment, see Image 6 .

[0056] The compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com