Preparation method of high-heat-resistant separation membrane material

A technology of separation membrane and high heat resistance, which is applied in semipermeable membrane separation, chemical instruments and methods, membranes, etc., and can solve problems such as poor thermal stability, unstable performance, and sudden drop in permeate flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

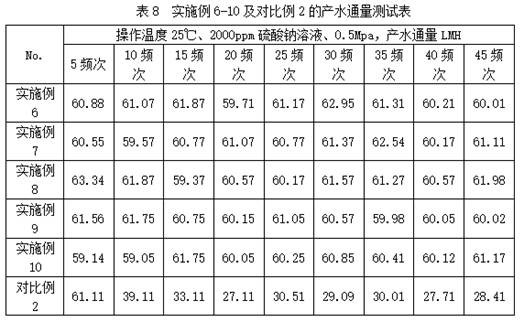

Embodiment 1-5 and comparative example 1

[0027]

[0028] 1) According to the configuration list in Table 1, put the modified polyimide with a molecular weight of 2200Da and a solubility of 55wt% in dimethylformamide, dimethylformamide, polyethylene glycol 400, and emulsifier Tween 80 into the batching kettle , set the temperature of the interlayer heat transfer oil in the batching kettle to 50°C, turn on the agitator and stir for 1-2 hours at a speed of 200-250rpm, add the quantitative polysulfone P3500, the temperature of the interlayer heat transfer oil in the batching kettle will rise to 90°C, and continue to stir. After the casting liquid is completely transparent, the feed liquid is filtered and removed by a filter, and then transferred to the storage tank. Use a vacuum pump to degas the casting liquid in the storage tank, and wait until the temperature of the casting liquid drops slowly to 20-30°C and keep it at a constant temperature until it is ready for use. At this time, the viscosity of the casting liqui...

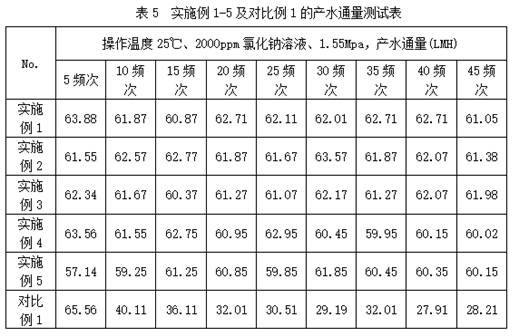

Embodiment 6-10 and comparative example 2

[0033]

[0034] The configuration list and supporting membrane thickness in Table 2 are the same as those in Table 1, but the composite membrane is a composite nanofiltration membrane.

[0035] Composite membrane water phase configuration: piperazine 1g / l, trisodium phosphate 3g / l, temperature 25°C, the support membrane is fully infiltrated and the surface moisture is removed before use. Composite membrane organic phase configuration: trimesoyl chloride 1.0g / l, isomerized dedecane solvent oil, temperature 25°C, after one-sided coating, the organic phase solution is heat-treated in an oven at 90°C for 5 minutes to obtain the high heat-resistant sodium Filter the composite membrane, and the prepared composite membrane is stored in deionized water for later use.

[0036] In the present invention, the support layer is prepared by enhancing the film pore structure, heat resistance, interface, etc. of the bulk polymer material with the polyimide modified material. The high heat-re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com