Automatic liquid metering and batching system

An automatic metering and batching system technology, applied in mixer accessories, dissolving, mixers, etc., can solve problems such as low efficiency, measurement error, and difficulty in tracking the batching process, to improve efficiency and quality, accurate batching measurement, real-time fast and accurate effect of ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

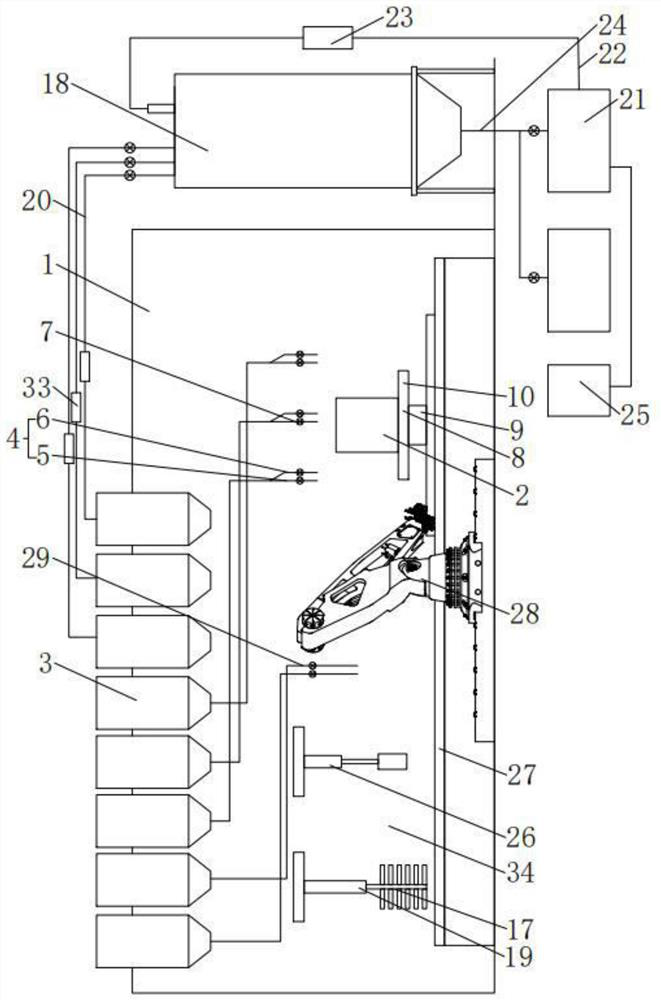

[0020] Embodiment one: a kind of liquid automatic metering batching system, such as Figure 1-Figure 2 As shown, it includes a frame 1. The frame 1 is provided with a raw material storage module, a feeding module 4, a weighing module and a transmission module. It also includes a stirring and discharging module 4 and a cleaning module. The raw material storage module is used to store raw materials. The feeding module 4 is used to pour the raw materials in the raw material storage module into the batching tank 2 for batching, the weighing module is used to accurately weigh the batching tank 2 containing raw materials, and the transmission module is used to transport the batching after the batching is completed The tank 2 and the stirring and discharging module 4 are used for stirring the raw materials on the transmission module and discharging after the stirring is completed, and the cleaning module is used for cleaning the batching tank 2 after the discharging is completed.

[...

Embodiment 3

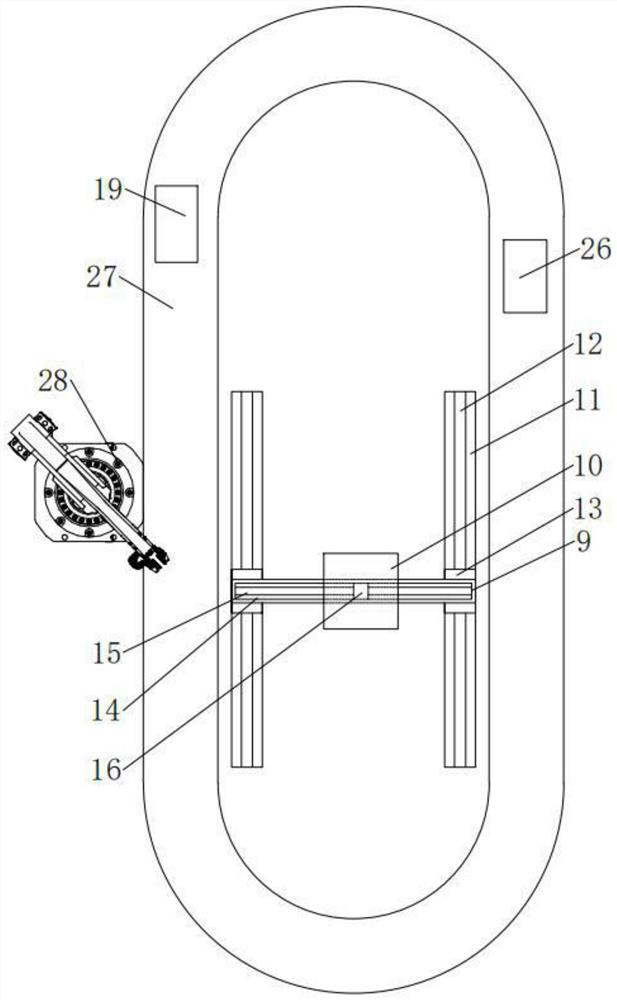

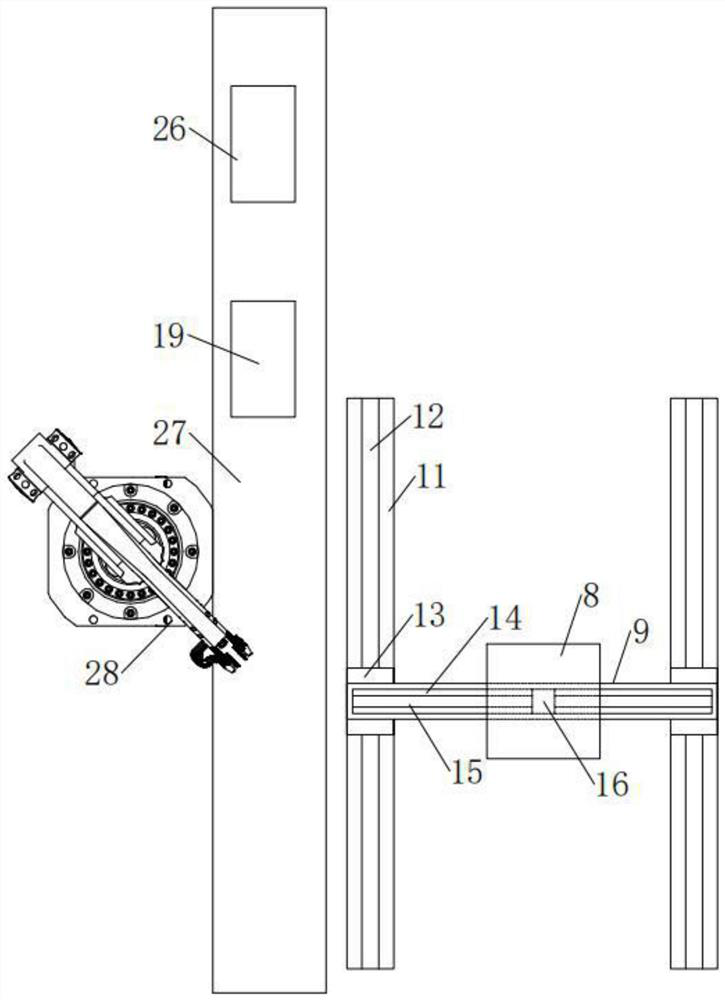

[0029] Embodiment three: as Figure 4 As shown, the transmission module includes a fixed table 30 and a mechanical arm 28. When the batching tank 2 is finished batching on the mobile platform, the mechanical arm 28 will transfer the batching tank 2 to the fixed table 30, and the rear slide rail is installed on the frame 1. 31. The mixer 17 and the pneumatic push rod 19 are slidably connected to the slide rail 31, and the cleaning module is also slidably connected to the slide rail 31. When the ingredients in the batching tank 2 are finished, slide the mixer 17 to the position corresponding to the fixed table 30, and then put the mixer 17 descends to the position close to the bottom of the batching tank 2 for stirring. After the stirring is completed, the mixer 17 is lifted by the pneumatic push rod 19, and then the CIP cleaning system in the cleaning module is moved to the position corresponding to the fixed table 30, and then the CIP cleaning is performed. The system makes it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com