Real-time measurement cabin for measuring oil mist deposition characteristic of wall surface

A real-time measurement, oil mist technology, applied in measurement devices, particle and sedimentation analysis, instruments, etc., can solve problems affecting equipment performance and service life, secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

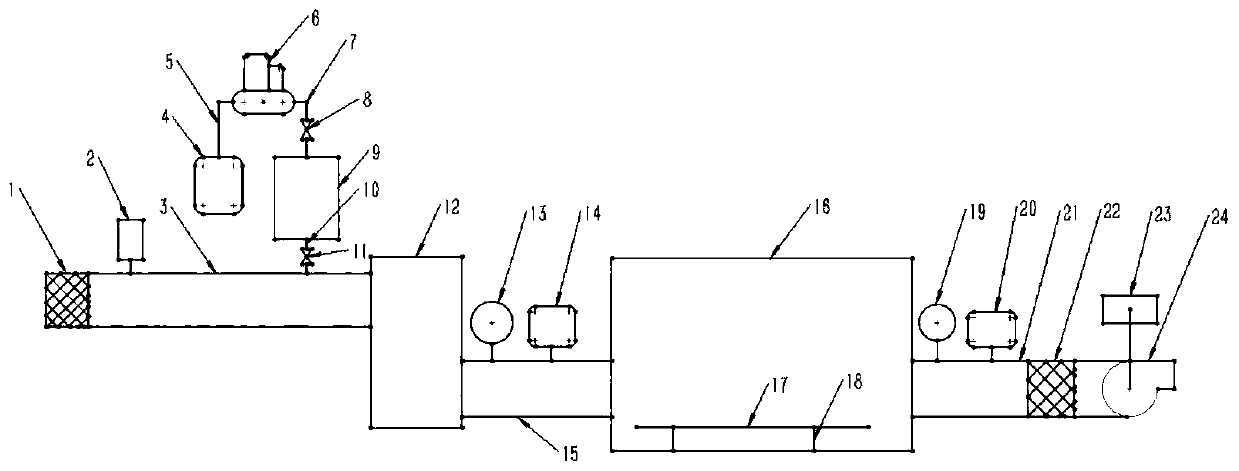

[0017] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only to illustrate the present invention, and are not intended to limit the present invention.

[0018] Measuring cabin of the present invention such as figure 1 As shown, the device includes: oil mist distribution system, main pipeline system, mixing box, monitoring system and test section system. The oil mist distribution system includes an air compressor 4, connecting pipe 1 5, air mass flow controller 6, connecting pipe 2 7, pressure regulating valve 1 8, oil mist generator 9, connecting pipe 3 10, and pressure regulating valve 2 11; The main pipeline system includes filter screen one 1; gas flow meter one 2; ventilation pipe one 3, ventilation pipe two 15, ventilation pipe three 21, filter screen two 22, frequency converter 23, centrifugal fan 24; air flow mixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com