Roundness measuring system and method

A roundness measurement and measurement system technology, which is applied in the field of measurement systems, can solve problems such as damage to the workpiece surface, large measurement errors, and workpieces that cannot be measured, so as to avoid damage and improve measurement accuracy and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

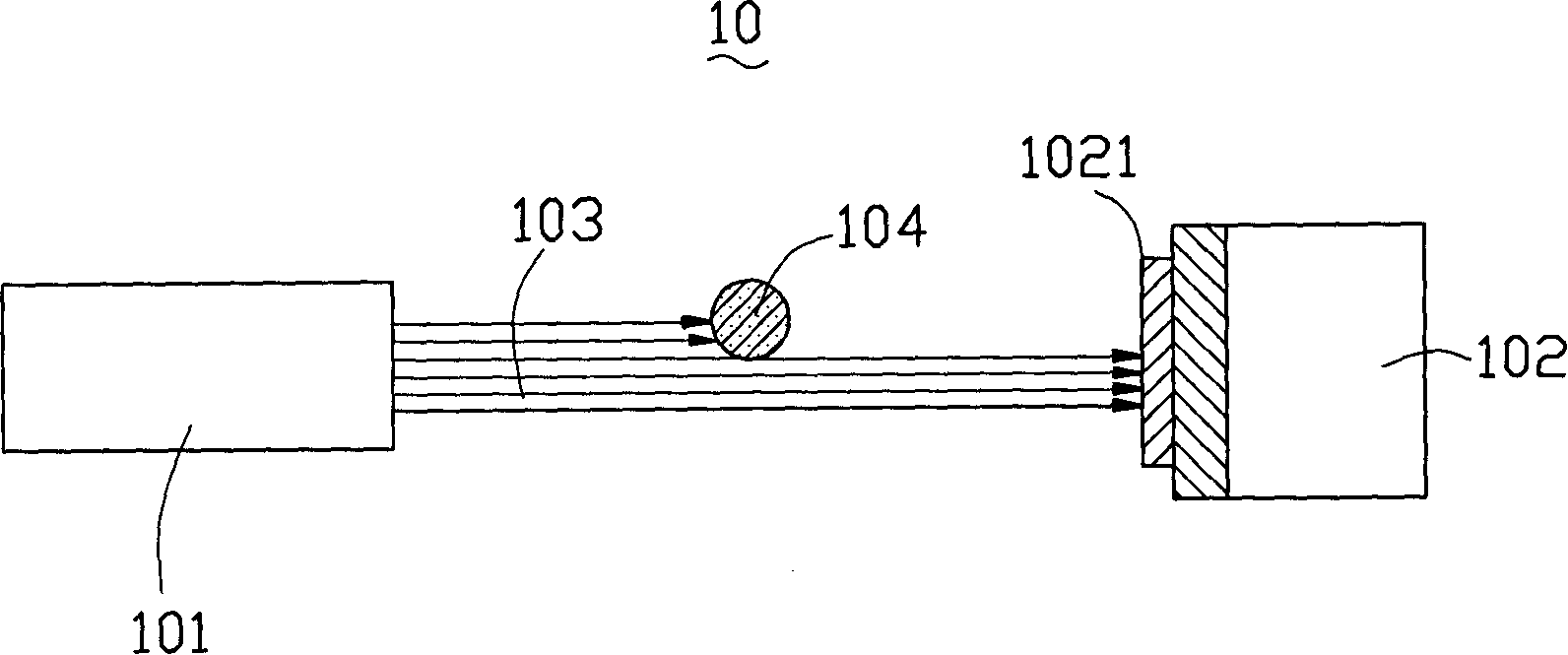

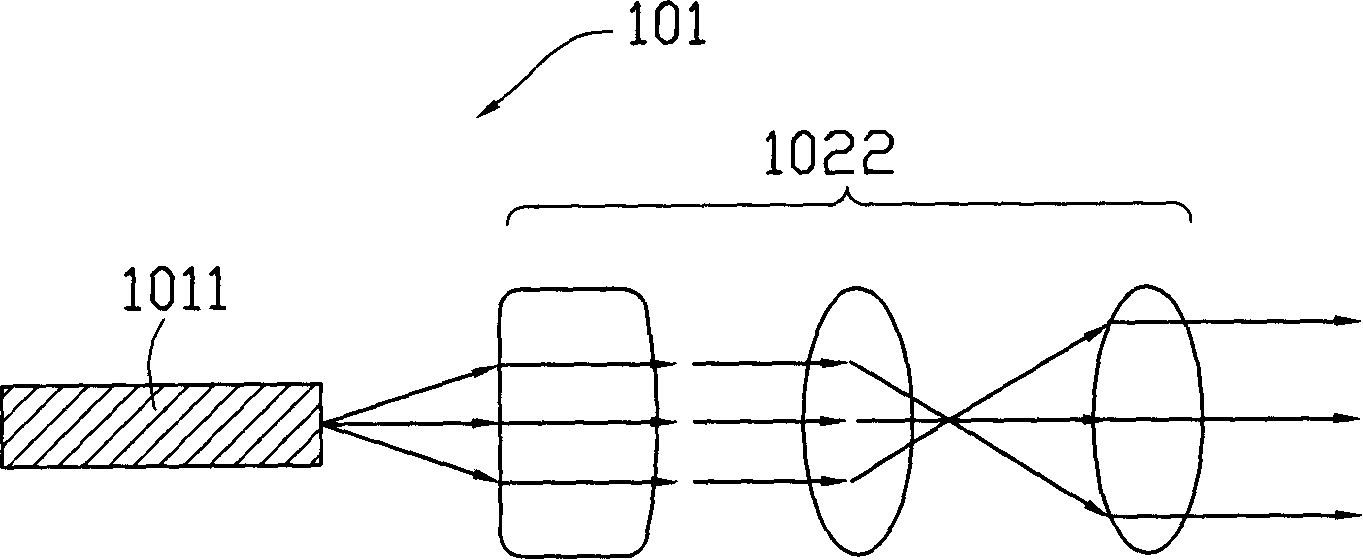

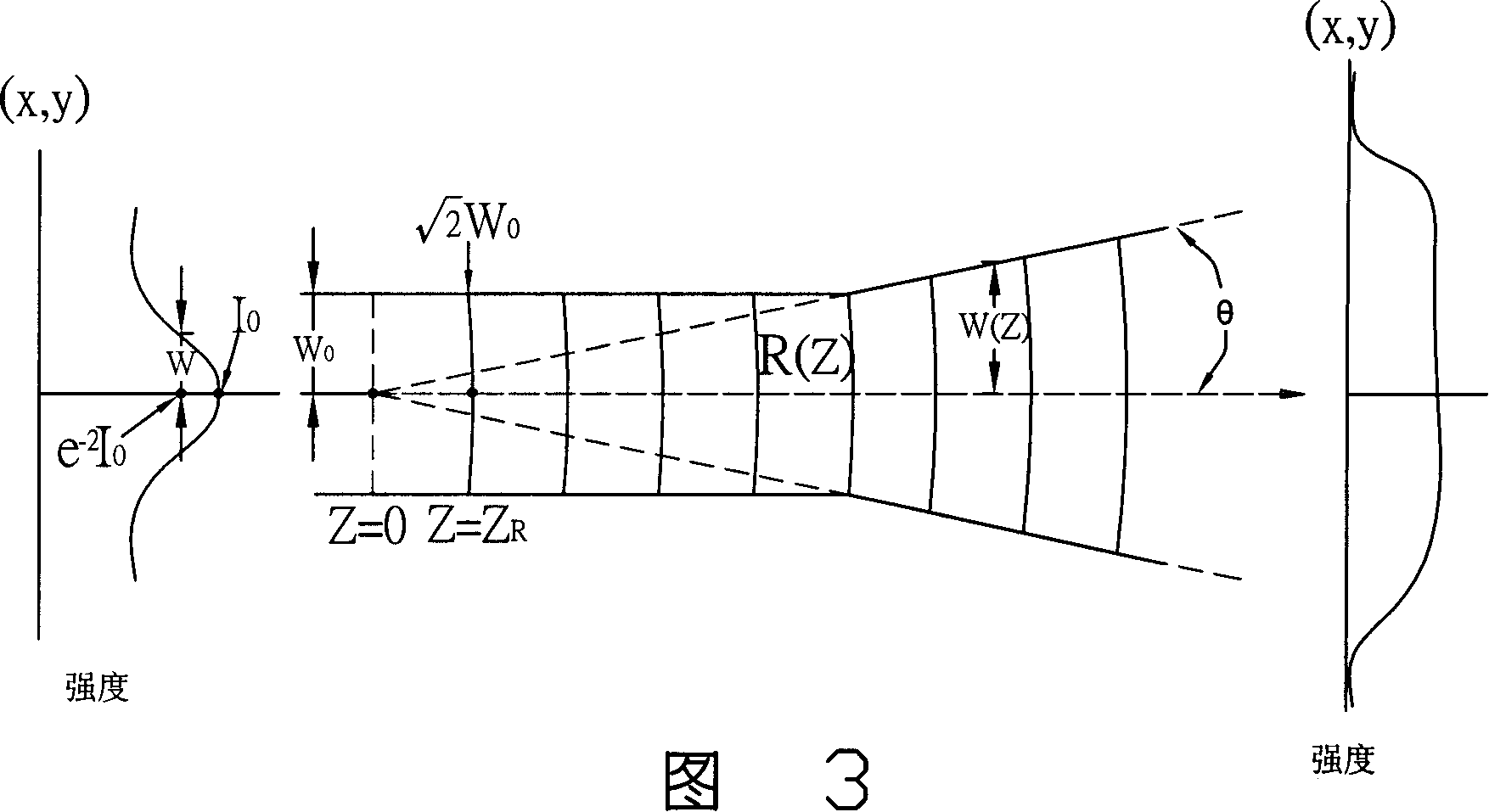

[0015] see figure 1 and figure 2 , the roundness measurement system 10 of the preferred embodiment of the present invention, the roundness measurement system 10 includes: a laser light source system 101 , a rotating device (not shown in the figure) and a sensing system 102 . The laser light source system 101 is composed of a laser light source 1011 and a plurality of lenses 1022 , which can emit a parallel laser beam 103 . The rotating device is disposed between the laser light source system 101 and the sensing system 102 . A workpiece 104 to be measured for roundness can be mounted on the rotating device, and the axis of the workpiece 104 is perpendicular to the laser beam 103 . Sensing system 102 includes a sensor 1021, an information processing module (not shown) and a display interface (not shown), in the information processing module, a database of light intensity signal and roundness conversion relationship is established, and the sensor 1021 senses The light intensit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com