Novel garbage sweeping, classifying and recycling system

A recycling system and garbage technology, applied in sorting, solid separation, solid waste removal, etc., can solve the problems of high degree of automation and difficult recycling of garbage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

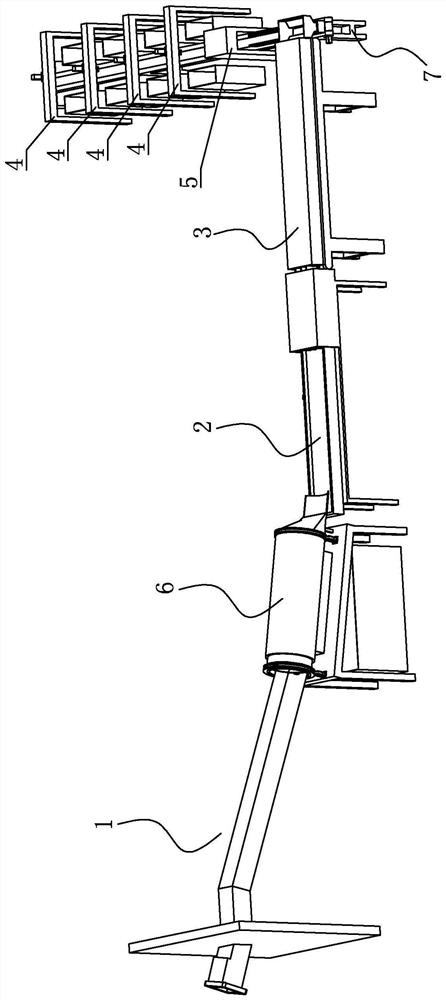

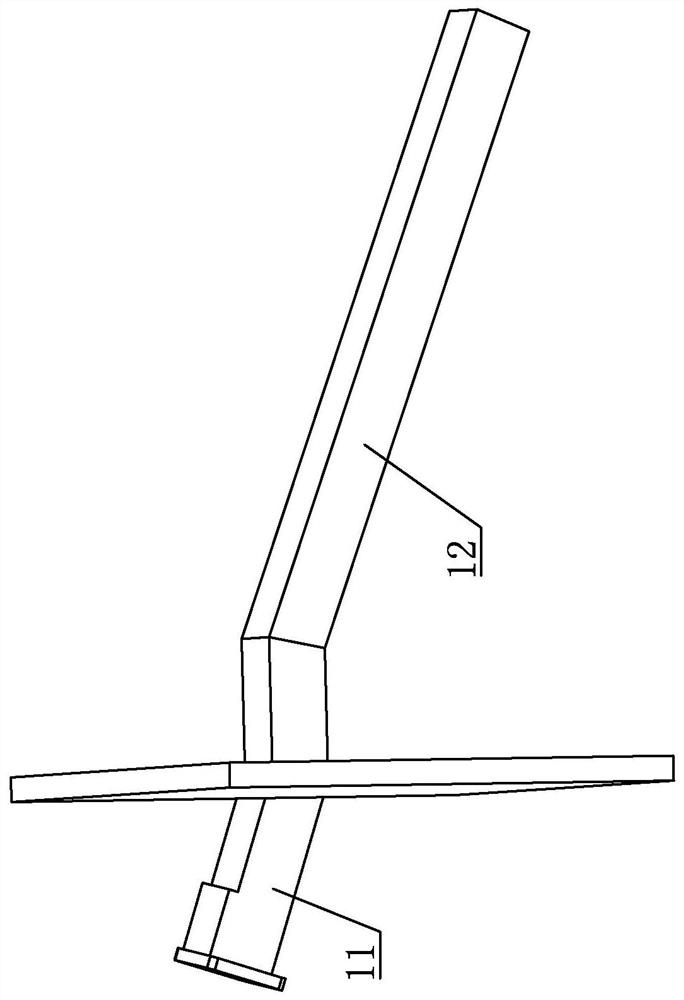

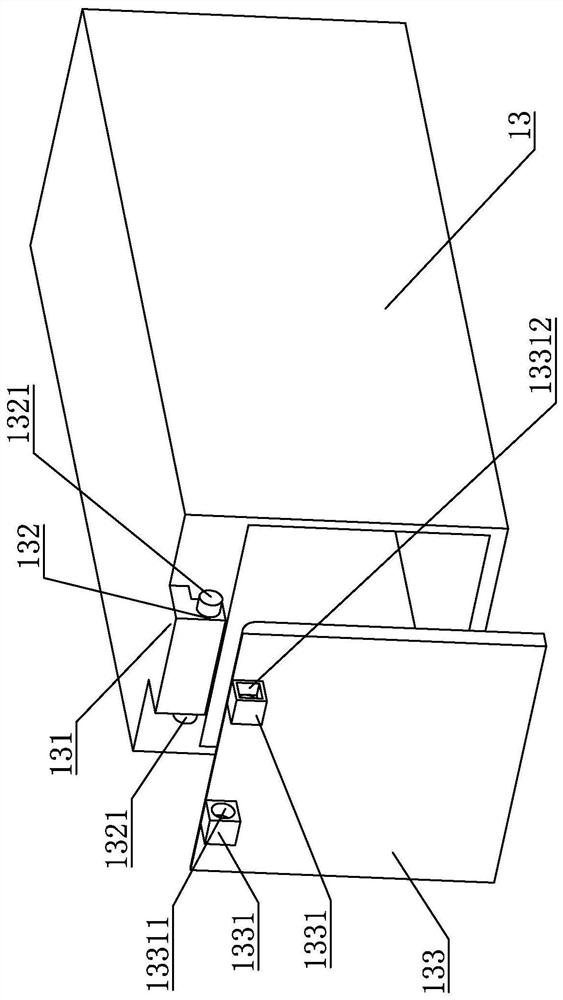

[0063] In the present invention, it is mainly used to recycle plastic product waste, glass product waste, and iron waste, etc., and it is necessary to sandblast fluorescent paint and fluorescent paint on the outer packaging of the product when the manufacturer of plastic product, glass product, and iron pop cans leaves the factory. It is a non-toxic and harmless fluorescent agent, and the colors of the fluorescent agents sprayed by different products are different; in the present invention, the ones close to the input ends of each mechanism are all upstream, and the ones close to the output ends of each mechanism are all downstream; Figure 1 to Figure 9 As shown, it is a kind of waste related to the present invention. In the present invention, it is mainly used to recycle plastic waste, glass waste, and iron wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com