Fine dispersion system for concrete preparation and working method

A fine dispersion and concrete technology, which is applied in the direction of clay preparation equipment, chemical instruments and methods, cement mixing equipment, etc., can solve the problems of insufficient dispersion of mortar and uneven top and bottom of mortar, achieve high degree of fine dispersion of mortar, and solve the problem of mortar up and down uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

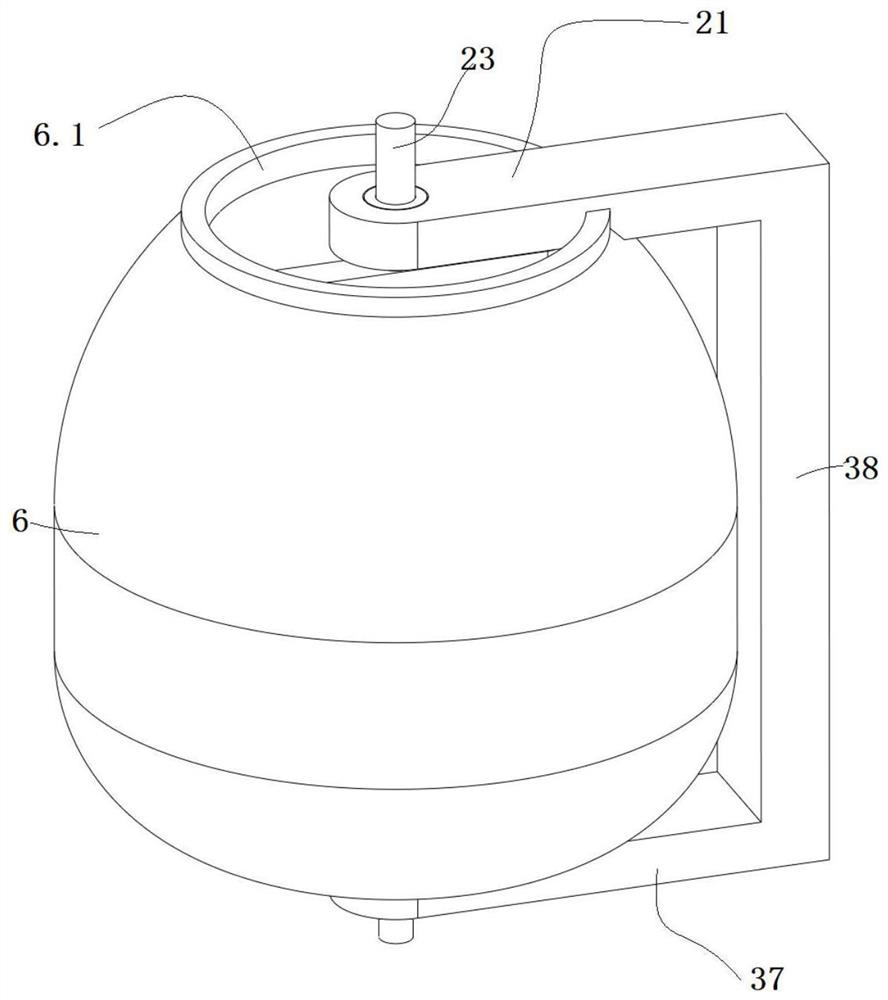

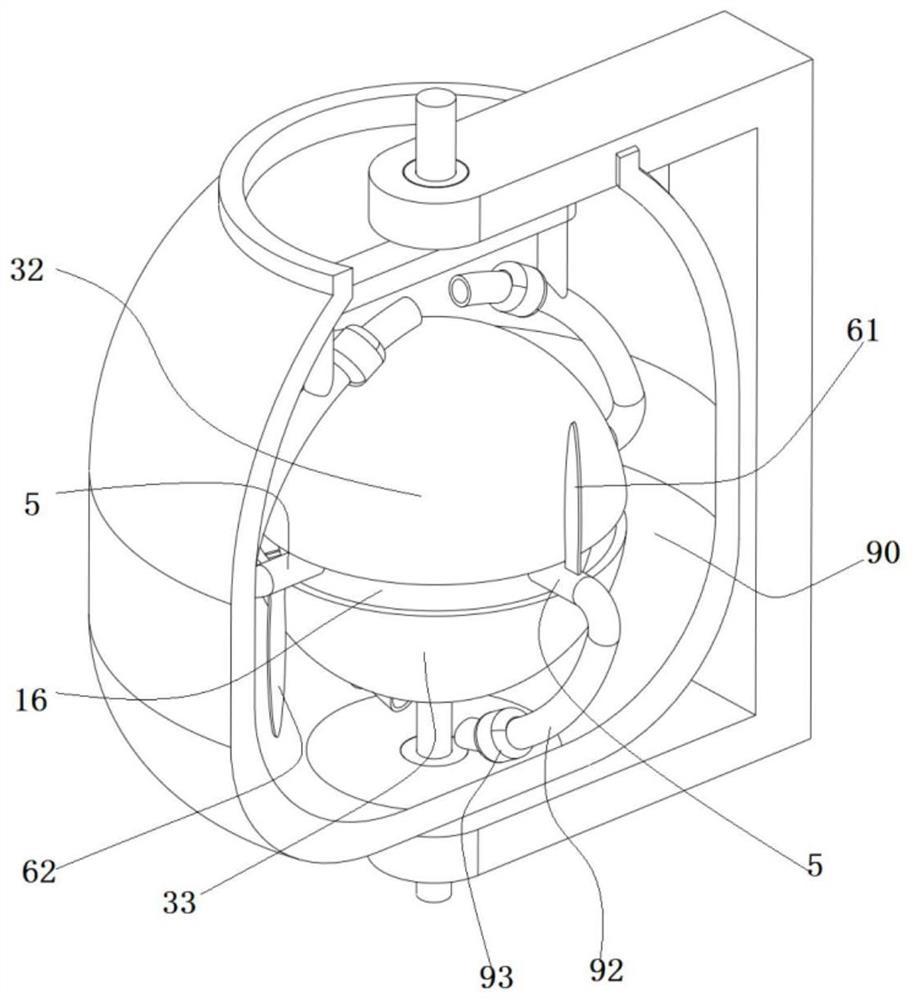

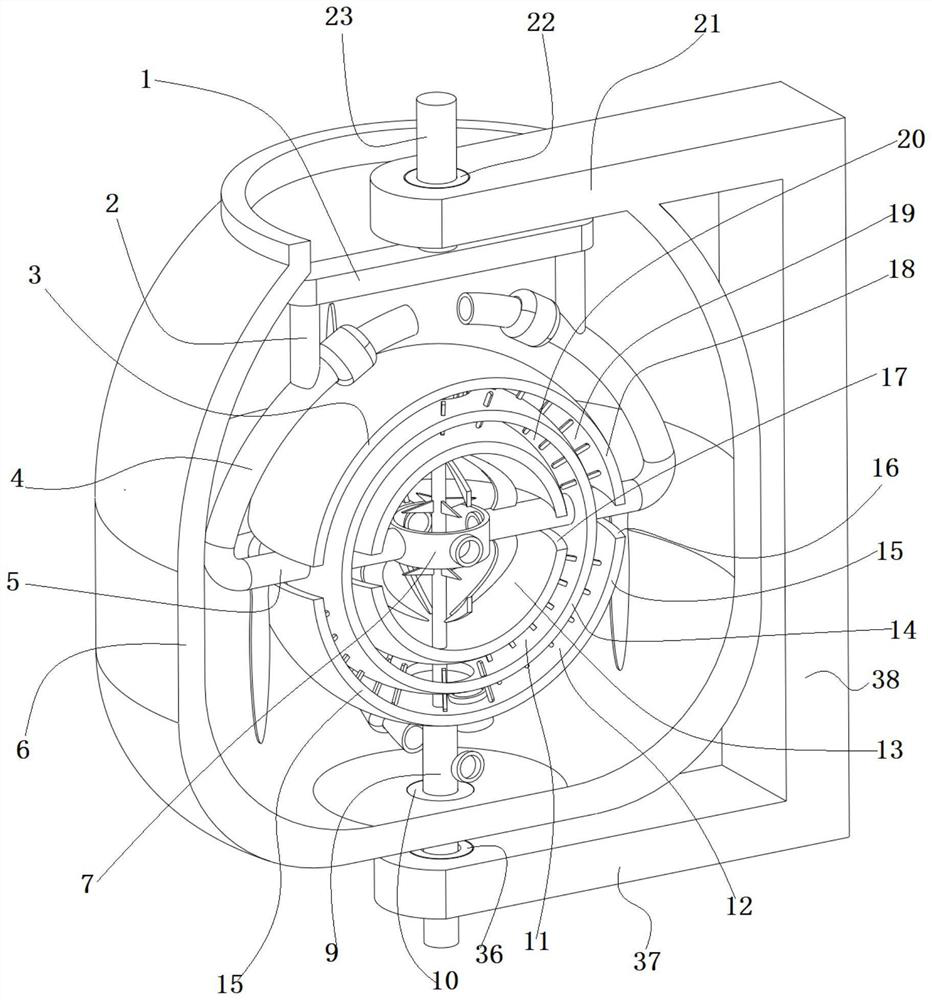

[0036] The present invention will be further described below with reference to the accompanying drawings.

[0037] Append Figure 1 to 10 The fine dispersion system prepared by the concrete, including the concrete fine stirring vessel 6, the container bin 90 in the concrete fine stirring container 6 is provided with a ventricular housing and a mid-ball housing 14 in the outer-to-internal distribution. And the inner ball housing.

[0038] The outer spherical housing is combined by the outer hemispherical housing 18 and the outer hemispheric housing 15, and the spacing between the outer hemispherion housing 18 and the outer sloppic housing 15 forms an outer ring mixed mortar overflow port 16; The spacing between the upper half of the housing 18 and the medium sphere housing 14 forms a first semi-ball housing mortar dispersion passage 19, and the spacing between the outer hemispherion housing 15 and the medium spherical housing 14 forms a second hemispheric shell mortar dispersion. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com