Concrete fine dispersion preparation system and process

A preparation system and refinement technology, applied in clay preparation devices, chemical instruments and methods, cement mixing devices, etc., can solve the problems of insufficiently finely dispersed mortar, uneven upper and lower mortar, etc. uneven top and bottom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

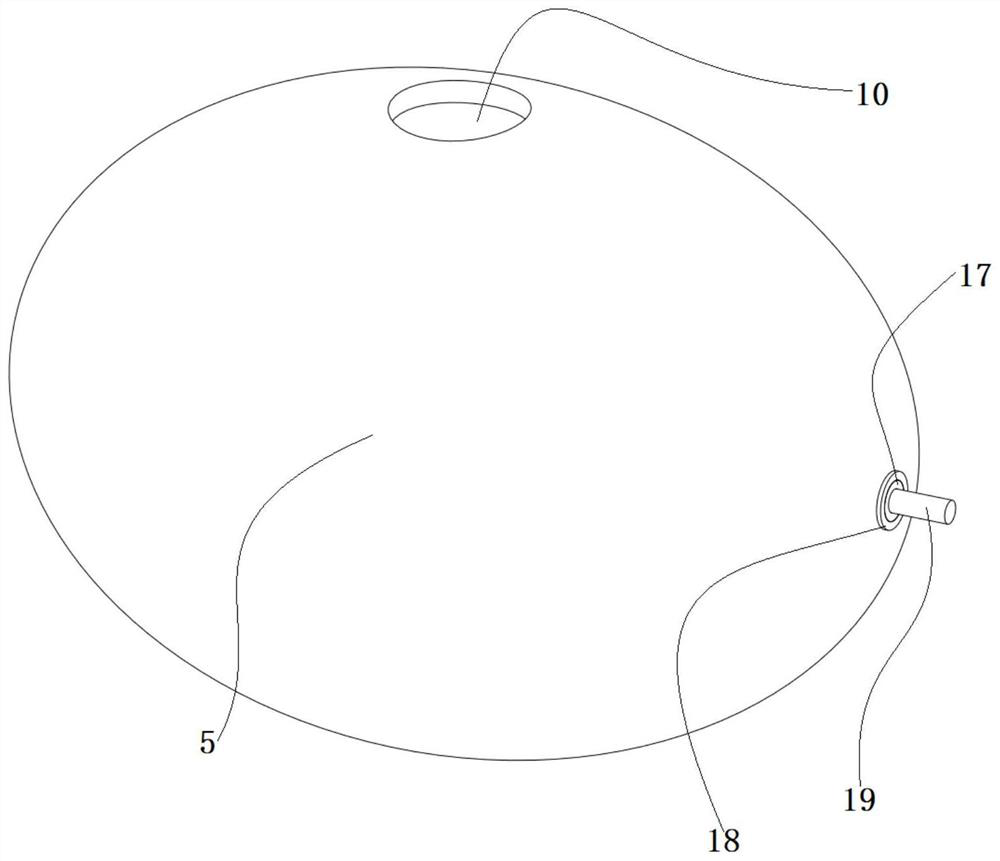

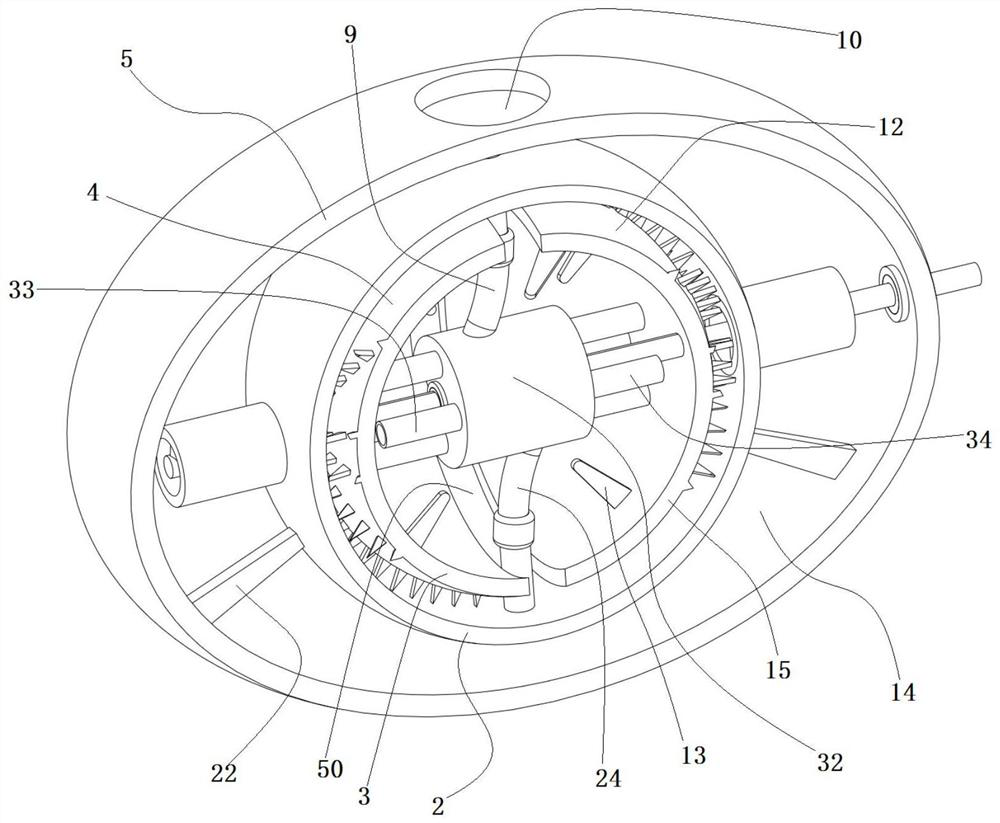

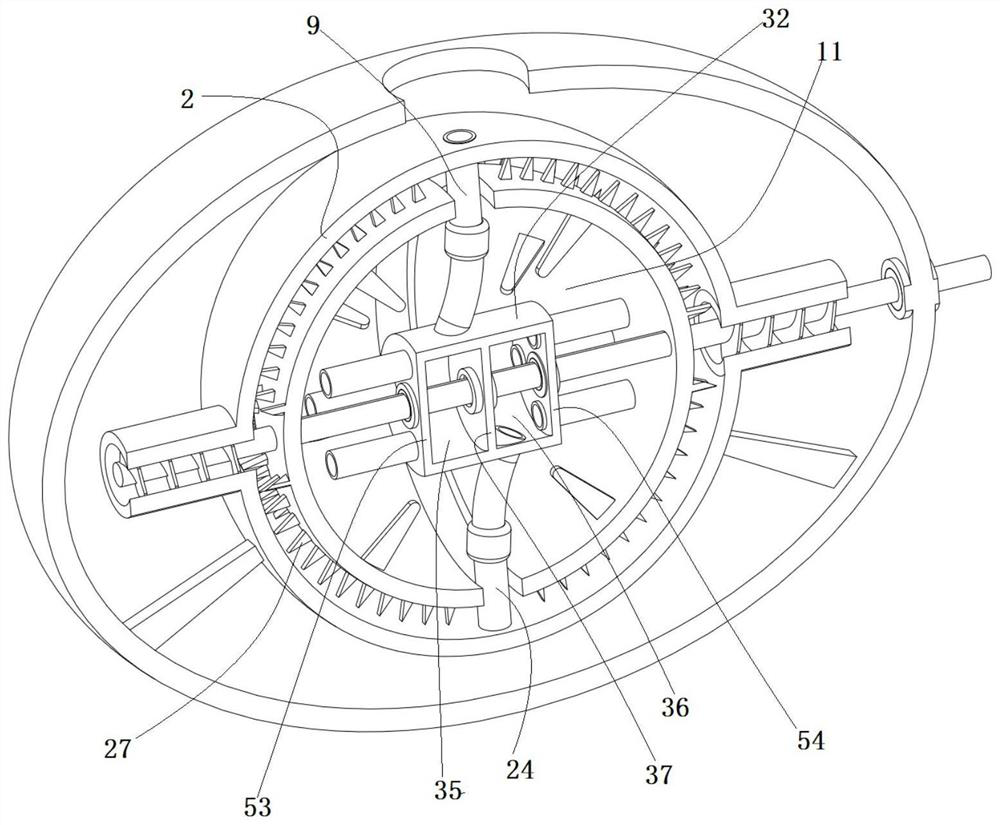

[0035] as attached Figures 1 to 8 The concrete fine dispersion preparation system shown includes an ellipsoidal agitator shell 5, inside the ellipsoidal agitator shell 5 is an ellipsoidal mortar bin 14, and the ellipsoidal agitator shell 5 is provided with a spherical agitator inner shell 2. The spherical center of the spherical agitator inner shell 2 coincides with the ellipsoid center of the ellipsoidal agitator shell 5; the interior of the spherical agitator inner shell 2 is provided with a mortar fine mixing unit .

[0036] The left and right ends of the spherical agitator inner shell 2 are respectively coaxially integrated with a left mortar circulation pipe 1 and a right mortar circulation pipe 16, and the axes of the left mortar circulation pipe 1 and the right mortar circulation pipe 16 are aligned with the The ellipsoidal major axis 97 of the ellipsoidal mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com