A kind of biochar preparation device of chili straw

A technology of biomass charcoal and preparation device, which is applied in the fields of biofuel, special form dry distillation, petroleum industry, etc., can solve the problems such as inconvenience of restricting and adjusting use, increasing drying effect, inconvenience of cooling treatment and use at the extruding and draining place.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

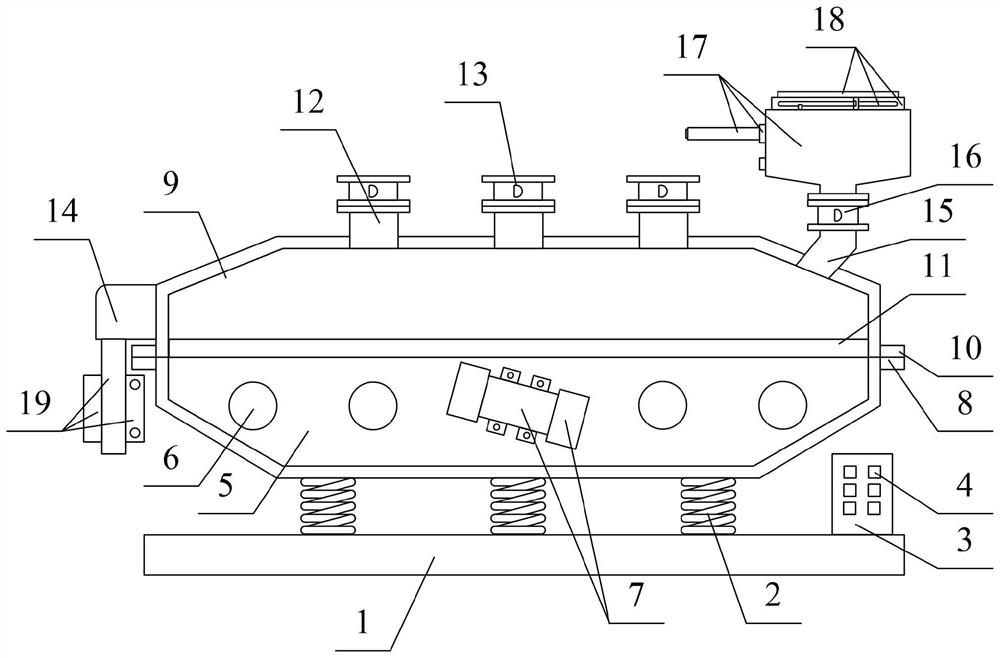

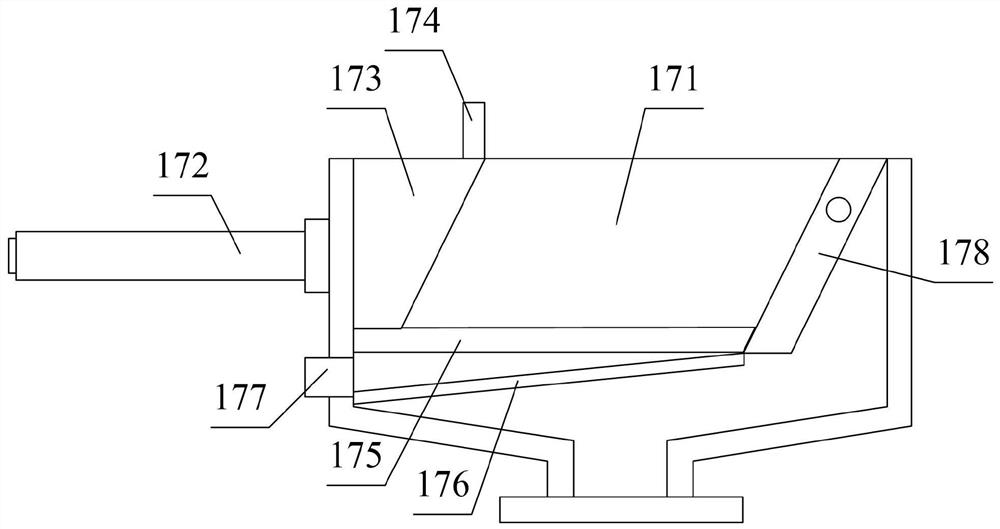

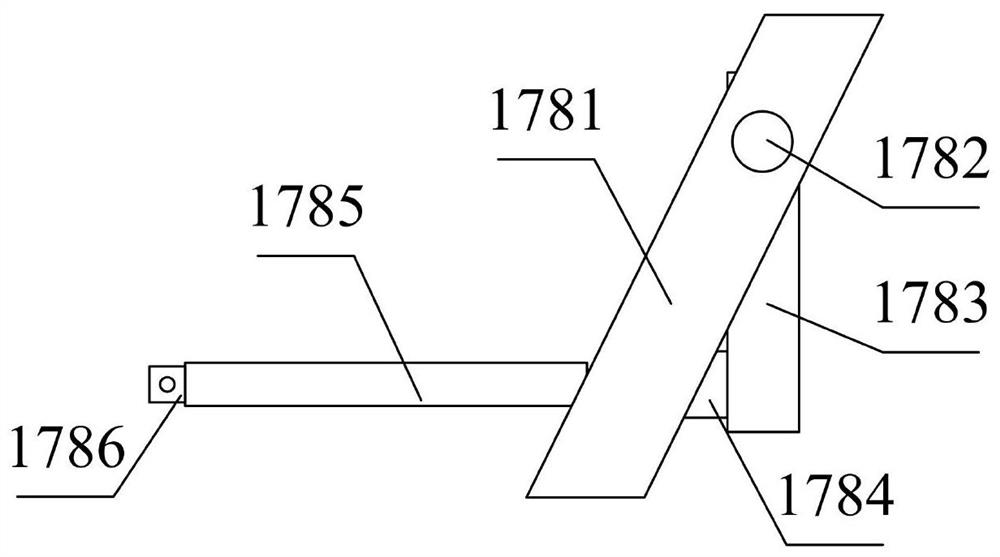

[0040] as attached figure 1 To attach figure 2Shown, a kind of biomass charcoal preparation device of pepper stalk comprises support base 1, support spring 2, controller 3, control switch 4, lower vibrating fluidized bed body 5, hot air inlet hole 6, vibrating motor 7, lower Assembly frame 8, upper vibrating fluidized bed body 9, upper assembly frame 10, fluidized bed plate 11, exhaust cylinder 12, exhaust valve 13, discharge steel box 14, feed pipe 15, feed valve 16, extrusion Press into the hopper structure 17, adjust the control plate frame structure 18 and the cooling discharge box structure 19, the support spring 2 is welded around the upper end of the support base 1, and the upper end of the support spring 2 is welded with the lower vibrating fluidized bed body 5; the controller 3 is installed on the front part of the upper right side of the support base 1 through bolts, and the front end of the controller 3 is inlaid with a control switch 4; the left and right sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com